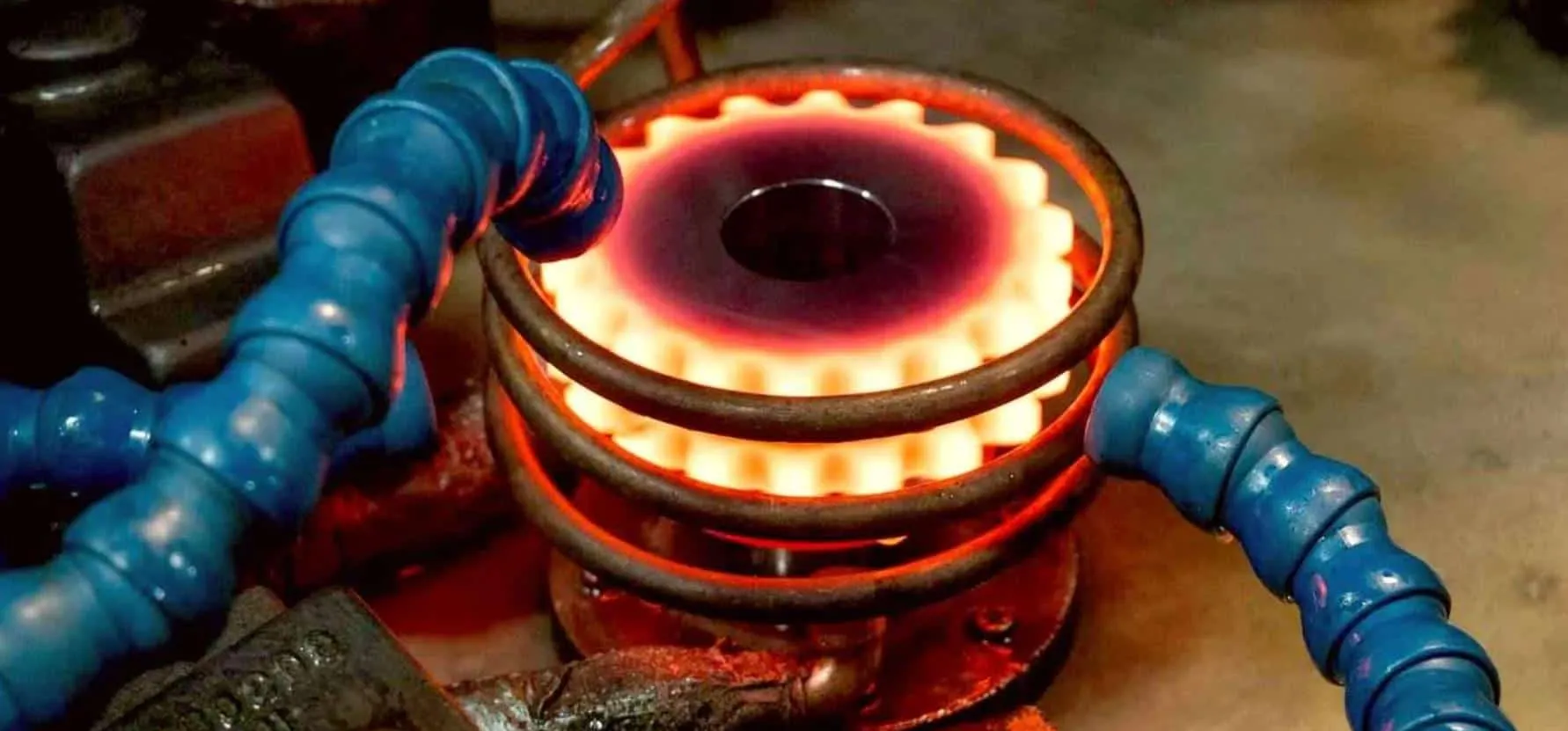

what’s induction strip heating?

Induction strip heating is a method of heating metal strips using electromagnetic induction. This process involves passing an alternating current through a coil, which creates a magnetic field that induces eddy currents in the metal strip. These eddy currents generate heat within the strip, allowing for precise and efficient heating. The induction strip heating process … Read more