What is an induction billets heater for hot billet forming?

An induction billets heater is a specialized piece of equipment used in the hot billet forming process. It uses electromagnetic induction to heat metal billets to the required temperature for shaping and forming.

The process of hot billet forming is a critical aspect of the manufacturing industry, where the transformation of metal into various shapes and products occurs. A fundamental component of this process is the heating of billets, which are long, solid bars or blocks of metal. The method employed to heat these billets significantly affects the efficiency, quality, and overall cost of production. This is where induction billet heaters come into play, offering a modern, efficient, and precise heating solution. In this comprehensive article, we will explore the technology behind induction billet heaters, their advantages, and their applications in the hot billet forming industry.

How does an induction billets heater work?

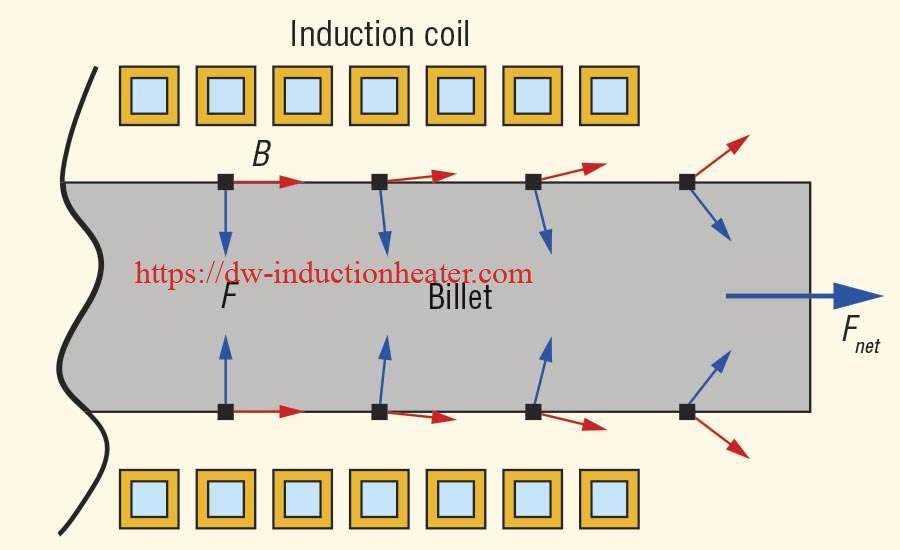

The induction billets heater works by using an electromagnetic field to generate heat within the metal billet. An alternating current is passed through a coil, creating a magnetic field. This magnetic field induces eddy currents within the billet, causing it to heat up rapidly.

Induction heating is based on the principle of electromagnetic induction, discovered by Michael Faraday in the 1830s. It involves generating eddy currents within a conductive material, such as a metal billet, by subjecting it to a varying magnetic field. The interaction between the magnetic field and the eddy currents produces resistive heat within the billet. An induction billet heater typically comprises an induction coil, power supply, and control system, all designed to heat billets uniformly to the desired temperature.

Components and Functionality:

1 Coil: The induction coil, often made from copper tubing, is the heart of the billets heater. It is designed to carry a high-frequency alternating current (AC). The shape and size of the coil are tailored to the dimensions of the billets to ensure efficient heating. When a billet is placed within or next to the coil, the alternating magnetic field induces a current in the billet, creating heat.

2. Power Supply: The power supply for an induction billet heater is an inverter that converts electrical energy from the grid to the high-frequency AC needed for the induction process. Modern power supplies are capable of delivering a wide range of frequencies, allowing for precise control over the heating process.

2. Power Supply: The power supply for an induction billet heater is an inverter that converts electrical energy from the grid to the high-frequency AC needed for the induction process. Modern power supplies are capable of delivering a wide range of frequencies, allowing for precise control over the heating process.

3. Control System: The control system is responsible for regulating the heating cycle, monitoring temperature, and ensuring that the billet is heated uniformly to the set specifications. This is typically achieved through the use of temperature sensors, feedback loops, and advanced software that adjusts the power supply in real time.

What are the advantages of using an induction billets heater?

Induction billets heaters offer several advantages over traditional heating methods such as gas furnaces or resistance ovens:

1. Efficiency: Induction heating is highly energy-efficient, as the heat is generated directly within the billet without the need for a transfer medium. This direct heating method minimizes heat loss and can significantly reduce energy consumption.

2. Precision: The ability to closely control the power and frequency of the induction heater allows for precise temperature control. This results in uniform heating of the billet, which is essential for maintaining the metallurgical properties of the metal during forming.

2. Precision: The ability to closely control the power and frequency of the induction heater allows for precise temperature control. This results in uniform heating of the billet, which is essential for maintaining the metallurgical properties of the metal during forming.

3. Speed: Induction heating can be much faster than traditional methods, as the heat is generated almost instantaneously within the billet. This reduces cycle times and increases throughput.

4. Safety: Since induction heating does not rely on combustion, it presents fewer safety hazards than flame-based heating. The absence of flames and reduced emissions contribute to a safer and cleaner working environment.

5. Flexibility: Induction billet heaters can be designed to accommodate a range of billet sizes and compositions, making them suitable for various applications within the metal forming industry.

What types of billets can be heated using an induction billets heater?

Induction billets heater can be used for heating a wide range of metal billets, including steel, aluminum, copper, and other alloys. The size and shape of the billets can vary, and the induction heater can be customized to suit specific requirements.

Applications in Hot Billet Forming:

Applications in Hot Billet Forming:

Induction billets heater are employed in a variety of hot billet forming processes, including forging, extrusion, and rolling. In forging, the heated billets are deformed between dies to form complex shapes. In extrusion, heated billets are forced through a die to create elongated products with uniform cross-sections. Rolling involves passing the heated billet through a series of rolls to achieve the desired shape and thickness.

Induction billets heaters represent a significant advancement in the field of hot billet forming. Their ability to deliver efficient, precise, and rapid heating has made them indispensable in modern manufacturing setups. With the continued focus on energy efficiency and production optimization, the role of induction heating in the metal industry is set to expand further, driving innovation and quality in the manufacturing processes of the future.