How to Make an Induction Heater

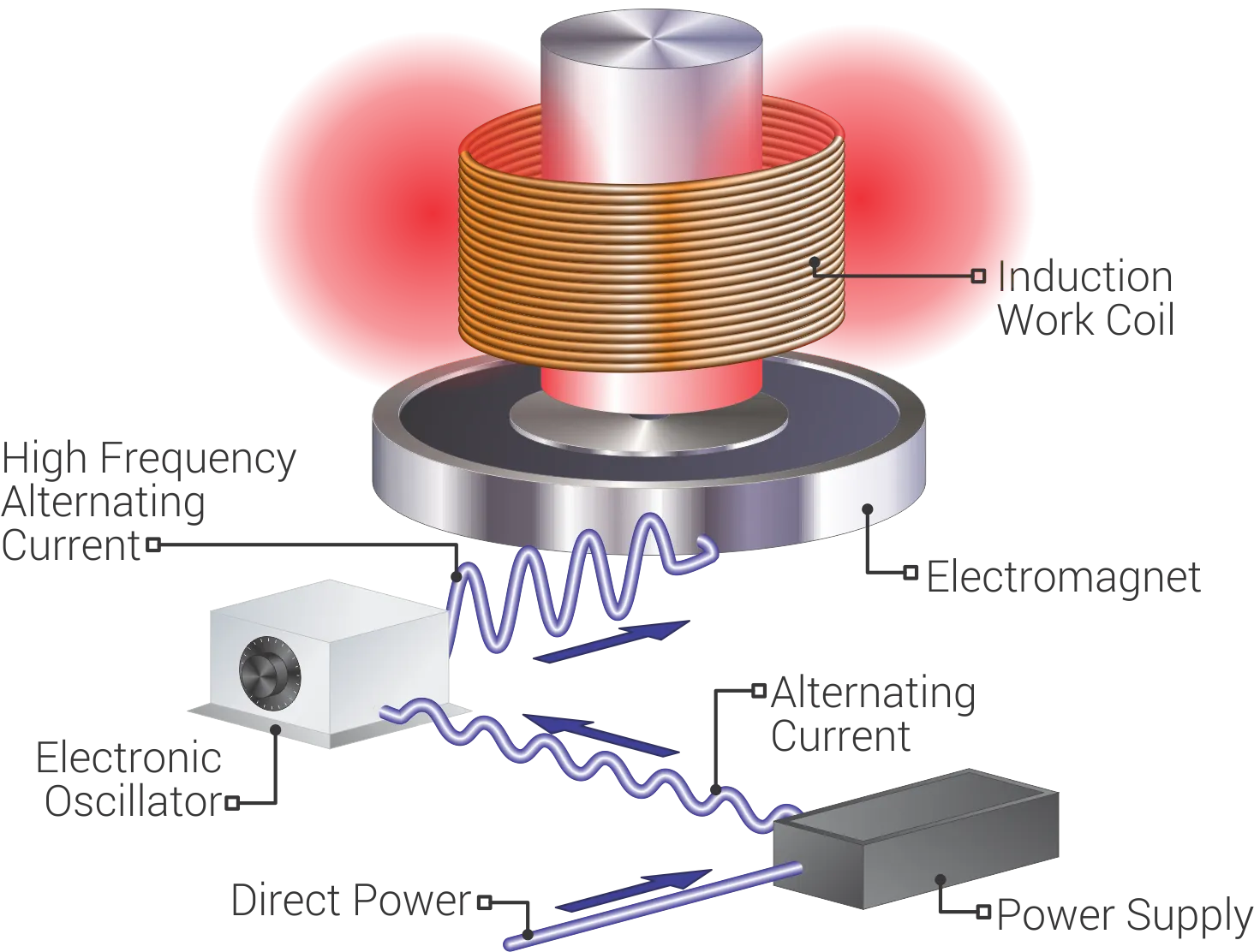

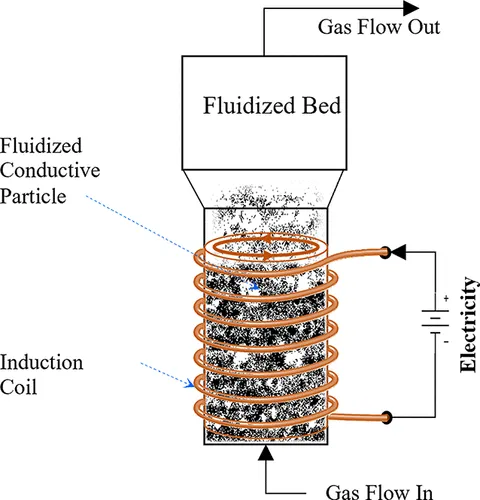

How to Make an Induction Heater: A Comprehensive Guide Table of Contents: Understanding How Induction Heating Works. 1 Safety Precautions When Making an Induction Heater. 2 Tools and Components You Will Need to Build an Induction Heater. 2 Detailed Circuit Design and Layout for an Induction Heater. 3 Key Elements of an Induction … Read more