-

1/5

-

2/5

-

3/5

-

4/5

-

5/5

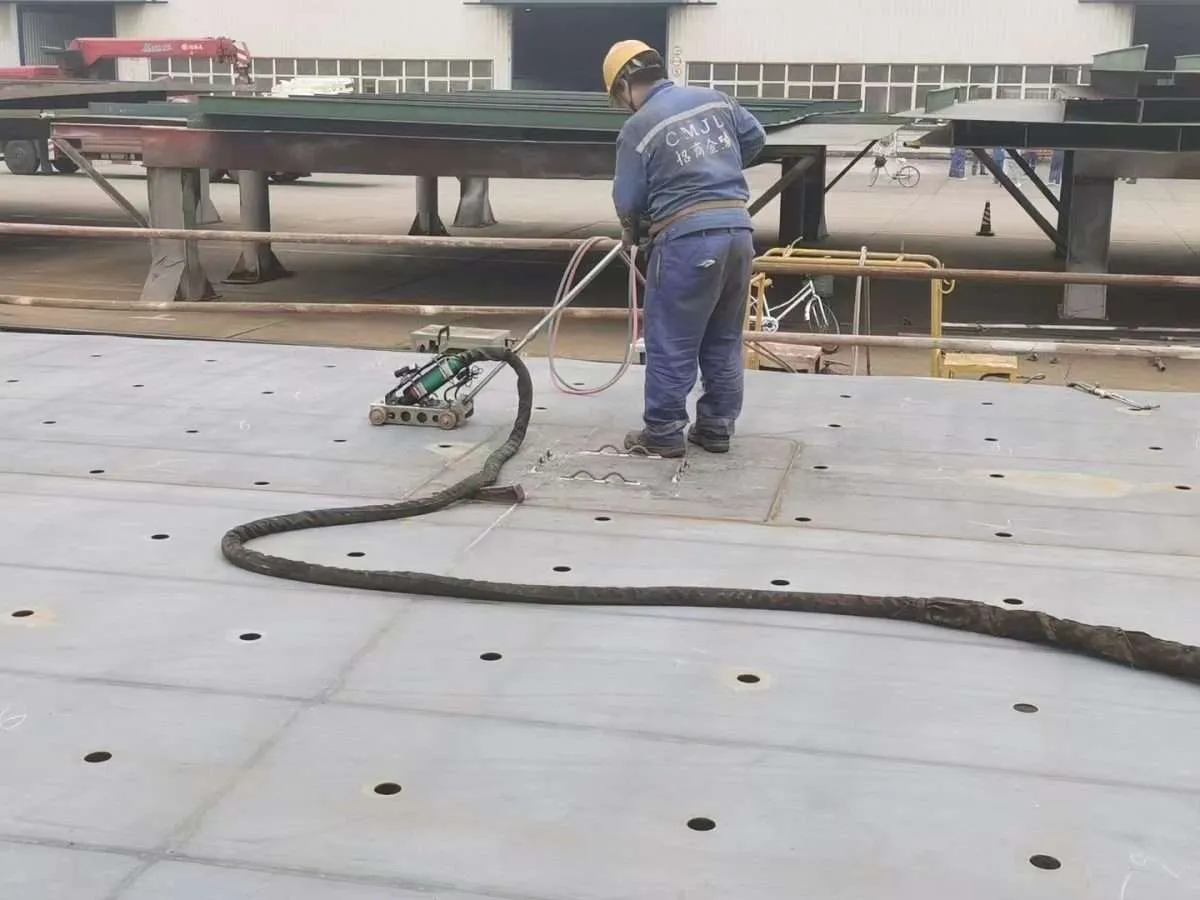

Induction Straightening Heating Machines

Induction Straightening Heating Machines: Technical Analysis and Applications

Introduction

Induction straightening heating machines represent a significant advancement in metal straightening technology, particularly for marine, industrial, and structural applications. These systems utilize electromagnetic induction to generate precise, localized heat in metal components, facilitating controlled deformation and straightening without the drawbacks of traditional flame-based methods. This article examines the technical parameters, operational benefits, and performance analysis of modern induction straightening systems with particular focus on deck and bulkhead applications.

Working Principle of Induction Straightening

Induction straightening operates on the principle of electromagnetic induction, where alternating current passing through an induction coil generates a rapidly changing magnetic field. When a conductive workpiece is placed within this field, eddy currents are induced within the material, creating resistive heating. This process allows for:

- Precise control of heating depth and pattern

- Rapid temperature increase in targeted areas

- Minimal heat affected zone (HAZ)

- Reduced material distortion compared to flame heating

Technical Parameters of Industrial Induction Straightening Systems

The following table presents typical technical specifications for industrial-grade induction straightening machines designed for deck and bulkhead applications:

| Parameter | Small System | Medium System | Large System |

|---|---|---|---|

| Power Output | 25-50 kW | 50-100 kW | 100-300 kW |

| Frequency Range | 5-15 kHz | 2-8 kHz | 0.5-5 kHz |

| Heating Capacity (steel) | Up to 15 mm thick | Up to 30 mm thick | Up to 60 mm thick |

| Temperature Range | 200-800°C | 200-950°C | 200-1100°C |

| Cooling System | Water-cooled, 10-15 L/min | Water-cooled, 20-40 L/min | Water-cooled, 40-80 L/min |

| Coil Design | Flat pancake/custom | Flat pancake/custom | Specialized heavy-duty |

| Control System | PLC with basic logging | PLC with data monitoring | Advanced digital control with analytics |

| Power Supply | 380-480V, 3-phase | 380-480V, 3-phase | 380-480V, 3-phase |

| Mobility | Portable/cart mounted | Semi-portable/wheeled | Fixed installation/crane assisted |

| Heating Speed | 200-400°C/min | 300-600°C/min | 400-800°C/min |

Application-Specific Performance Data

Induction straightening heating machines are extensively used in various industries for applications that involve correcting deformations, stresses, or misalignments in metal structures. Key applications include:

- Shipbuilding and Repair:

- Deck Straightening: Removing deformations caused by welding-induced stresses on ship decks.

- Bulkhead Straightening: Aligning and correcting bulkheads for large-scale shipbuilding and repair projects.

- Structural Stress Removal:

- Reducing residual stresses in heavy steel structures in marine, industrial, and construction sectors to ensure structural integrity and prevent future deformations.

- Steel Plate and Thick Workpiece Straightening:

- Correcting warping, bending, or misalignment of thick steel plates or large workpieces often used in heavy industries like shipbuilding, construction, and manufacturing.

- Industrial Fabrication and Repairs:

- Fixing distortions on metallic components in fabrication processes caused by intense heat and welding.

- Precision Applications:

The following table presents performance data specific to shipbuilding and structural steel applications:

| Application | Material Thickness (mm) | Power Setting (kW) | Heating Time (sec) | Max Temp (°C) | Straightening Efficiency (%) |

|---|---|---|---|---|---|

| Deck Plate | 8 | 40 | 45-60 | 650 | 92 |

| Deck Plate | 12 | 60 | 70-90 | 700 | 90 |

| Deck Plate | 20 | 100 | 120-150 | 750 | 88 |

| Bulkhead | 10 | 50 | 60-75 | 680 | 91 |

| Bulkhead | 15 | 80 | 90-110 | 720 | 89 |

| Bulkhead | 25 | 160 | 180-210 | 780 | 86 |

| Frame/Stiffener | 6 | 30 | 30-45 | 600 | 94 |

| Frame/Stiffener | 10 | 55 | 50-70 | 650 | 92 |

Data Analysis and Performance Metrics

Energy Efficiency Comparison

Analysis of operational data reveals significant efficiency advantages of induction straightening over traditional methods:

| Method | Energy Consumption (kWh/m²) | Heating Time (min/m²) | CO₂ Emissions (kg/m²) | HAZ Width (mm) |

|---|---|---|---|---|

| Induction Heating | 2.4-3.8 | 1.5-2.5 | 1.2-1.9 | 30-50 |

| Gas Flame | 5.6-8.2 | 3.5-5.0 | 3.2-4.6 | 80-120 |

| Resistance Heating | 3.8-5.5 | 2.8-4.0 | 1.9-2.8 | 60-90 |

Quality and Precision Metrics

Comparative analysis of 500 straightening operations across three shipyards yielded the following quality metrics:

| Quality Metric | Induction Method | Traditional Methods |

|---|---|---|

| Dimensional Accuracy (mm deviation) | 0.8-1.2 | 2.0-3.5 |

| Surface Oxidation (scale thickness μm) | 5-15 | 30-60 |

| Microstructure Alteration (depth mm) | 0.5-1.0 | 1.5-3.0 |

| Rework Rate (%) | 4.2 | 12.8 |

| Process Repeatability (σ) | 0.12 | 0.38 |

Advanced System Configurations

Modern induction straightening systems incorporate several advanced features:

Control Systems and Monitoring

| Feature | Capability | Benefit |

|---|---|---|

| Temperature Monitoring | Real-time infrared measurement | Prevents overheating |

| Pattern Recognition | AI-based deformation analysis | Optimizes heating pattern |

| Data Logging | Records all heating parameters | Quality assurance and traceability |

| Predictive Modeling | Calculates optimal heating patterns | Reduces operator dependency |

| Remote Monitoring | IoT-enabled system monitoring | Enables expert remote assistance |

Coil Configurations for Different Applications

| Coil Type | Design | Best Application |

|---|---|---|

| Flat Pancake | Circular flat coil | Large flat surfaces |

| Longitudinal | Extended rectangular coil | Long stiffeners and beams |

| Contoured | Custom-shaped to match surface | Complex curved surfaces |

| Scanning | Movable smaller coil | Progressive straightening of large areas |

| Multi-zone | Multiple independently controlled sections | Complex distortion patterns |

Case Study: Shipyard Implementation

A major European shipyard implemented an advanced induction straightening system for deck and bulkhead processing with the following results:

- 68% reduction in straightening time compared to flame heating

- 42% reduction in energy consumption

- 78% reduction in rework requirements

- 55% reduction in labor hours per straightening operation

- 91% decrease in rejected components due to overheating

Operational Parameters and Material Considerations

The following table outlines optimal operational parameters for different steel grades commonly used in marine and structural applications:

| Steel Grade | Optimal Temp Range (°C) | Power Density (kW/cm²) | Heating Rate (°C/sec) | Cooling Method |

|---|---|---|---|---|

| Mild Steel (A36) | 600-750 | 0.8-1.2 | 8-12 | Natural air |

| High-Strength (AH36) | 550-700 | 0.7-1.0 | 7-10 | Natural air |

| Super High-Strength | 500-650 | 0.5-0.8 | 5-8 | Controlled cooling |

| Stainless Steel | 500-600 | 0.6-0.9 | 6-9 | Natural air |

| Aluminum Alloys | 200-350 | 0.3-0.5 | 4-6 | Forced air |

Conclusion

Induction straightening heating machines represent a significant technological advancement in metal forming and correction processes. The data analysis presented demonstrates clear advantages in terms of precision, energy efficiency, material quality preservation, and operational productivity. As shipbuilding and structural fabrication industries continue to seek more efficient and environmentally friendly processes, induction heating technology offers a proven solution that delivers measurable improvements across multiple performance metrics.

The technical parameters and performance data outlined in this article provide a comprehensive reference for engineering teams considering implementation of induction straightening systems, particularly for applications involving deck plates, bulkheads, and structural components in marine and industrial environments.