-

1/3

-

2/3

induction heating aluminium

Induction heating aluminium susceptor for powder expansion with high frequency heating system

Objective Expand powder into solid form for use in crash helmets

Material Microspheric powder Aluminium chamber 110mm (4.3 in.) diameter x 35mm (1.3 in.) deep used to hold powder

Temperature 150 ºC (302 ºF)

Frequency 20 kHz

Process Time 120 seconds

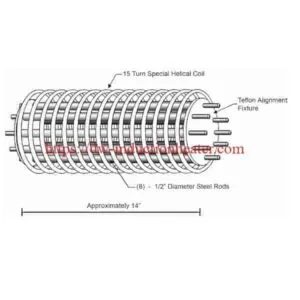

Equipment • DW-MF-25kW induction heating system, equipped with a remote workhead containing (4) 2.6 μF capacitors (for a total of 2.6 μF).

• Two pancake coils 110mm (4.3 in) dia. with 45mm (1.8 in.) gap, in a headphone configuration designed and developed specifically for this application.

Process The bottom of the susceptor chamber is sprayed with a release agent and microspheric powder is added to the chamber. The chamber is heated for 120 seconds to reach 150º C (302º F) changing

the powder into solid form. It is then allowed to air cool to 70º C (158º F) and removed from the chamber.

Results/Benefits Induction heating:

• reduces cycle time for increased production

• energy efficient – only heating the part allowing small production runs

• is very flexible allowing a variety of molds to be used