-

1/7

-

2/7

-

3/7

-

4/7

-

5/7

-

6/7

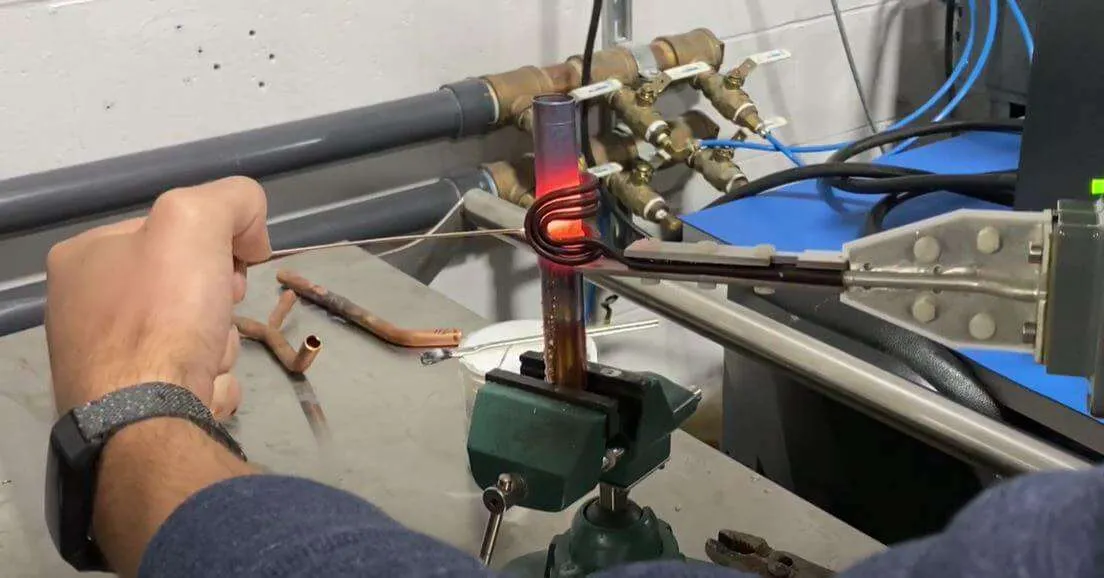

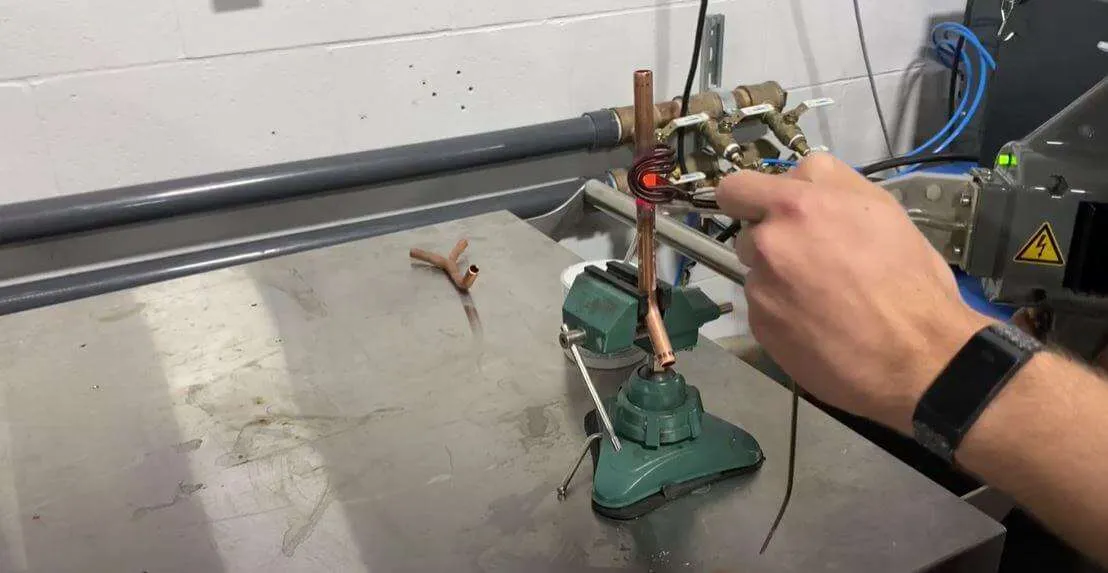

handheld induction brazing HVAC tubing

Handheld Induction Brazing HVAC Tubing

Refrigeration piping is always brazed as brazing makes a very solid leak-free joint that withstands high and low temperatures and pressures. When soldering refrigeration pipe it is best to use solder which has a composition of silver in it as the silver bounds with the copper and makes for an excellent leak free strong joint (capillary attraction).

HLQ Induction are experts at devising customized induction heating solutions for brazing of compressor parts, heating elements and heat distributors.

HLQ Induction are experts at devising customized induction heating solutions for brazing of compressor parts, heating elements and heat distributors.

Air conditioners have several parts that are brazed. The most common materials are copper and aluminium:

Aluminium parts, for example evaporator and condenser connections (tube-to-tube, tube-to-block, tube-to-tank)

Tube-to-fittings on the condenser unit

Tube-to-fittings on the evaporator unit

Tube-to-fittings on the compressor

Tube-to-valves in distribution systems

Induction Brazing is similar to soldering except the temperature is above 800 degreesF.

For copper, the brazing compound most commonly used is commonly called sil-phos as seen on the left.

There are several types of this compound.

15% Phosphorus/Copper/Silver Alloy is one type that uses 15% silver and is the standard for service techs doing repairs of refrigeration equipment.5% Phosphorus/Copper/Silver Alloy is another compound that is cheaper and some say works well for repairs. It does not work as well as 15%.

There is also a Phosphorus/Copper Alloy with no silver that I find to be largely useless for repairs.

Copper Brazing for the HVAC Industry

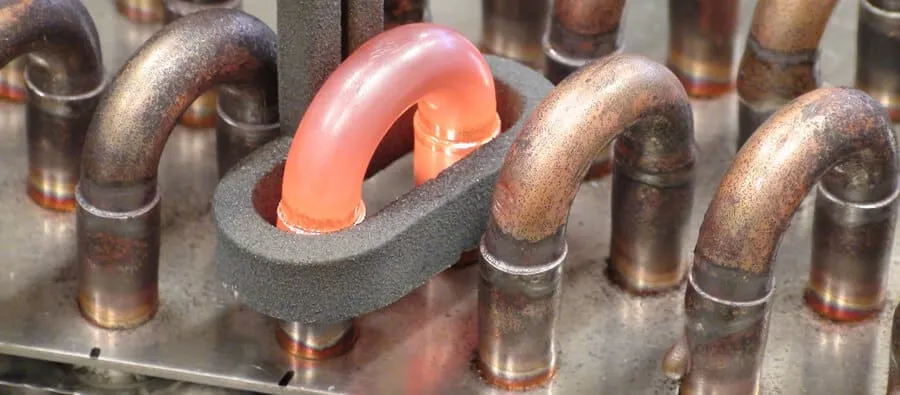

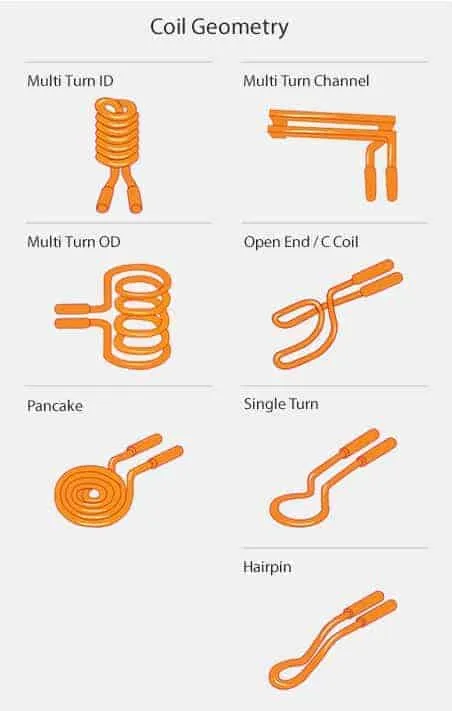

Multiple copper tubes silver brazed by MSI Automation’s proprietary induction brazing technology.Induction heating with the proper induction heating coil technology can silver braze multiples of copper tube ends in one shot. This procedure eliminates tedious hand torch brazing, improves consistency and reduces the chance of leaking connections.

Joint brazed between the copper tube and brass body is complete. Heating time using MSI’s special induction heating coil is 1/4 that of conventional round copper tube coil designs.