-

1/3

-

2/3

Preheating Turbine Blade for Welding

Induction Preheating Turbine Blade for Welding Application

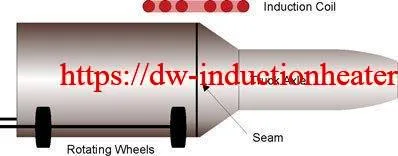

Objective: Induction PreHeating a turbine blade to 1850 ºF (1010 ºC) for a welding application

Material : Steel turbine blade

Temperature: 1850 ºF (1010 ºC)

Frequency: 305 kHz

Induction Heating Equipment: DW-UHF-6kW-I 150-400 kHz induction heating system equipped with a remote heat station containing two 1.5 μF capacitors.

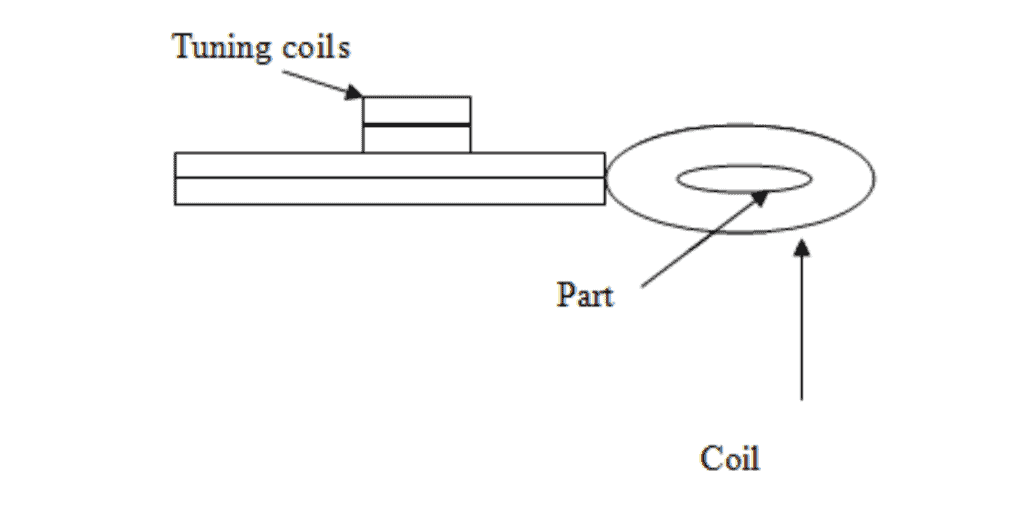

– A single position one-turn induction heating coil designed and developed specifically for this application

Process The single position one-turn induction heating coil was designed to heat the tip of the turbine blade. With a 6kW induction heating power supply, the turbine blade was heated to temperature within the targeted time of one minute.

Results/Benefits

Speed: The client wanted the part heated to temperature within one minute, which the process achieved

– Precision: The client desired uniform heating across the tip of the blade, which was attained with the proposed process

– Part quality: The end result is a preheating process that allows the part to move quickly to the welding step while

meeting all quality requirements