-

1/3

-

2/3

Induction preheating welding automotive transaxle

Induction preheating welding automotive transaxle

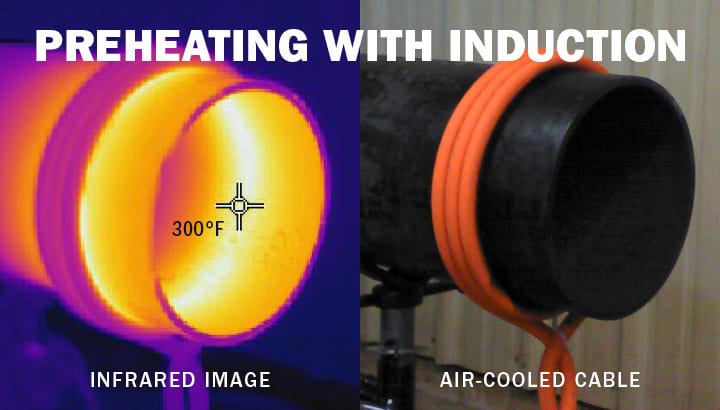

Objective: To preheat a 3.6” (91 mm) outside diameter steel axle with three weld lines to 662 ºF (350 ºC) with each weld line being heated to temperature within five seconds

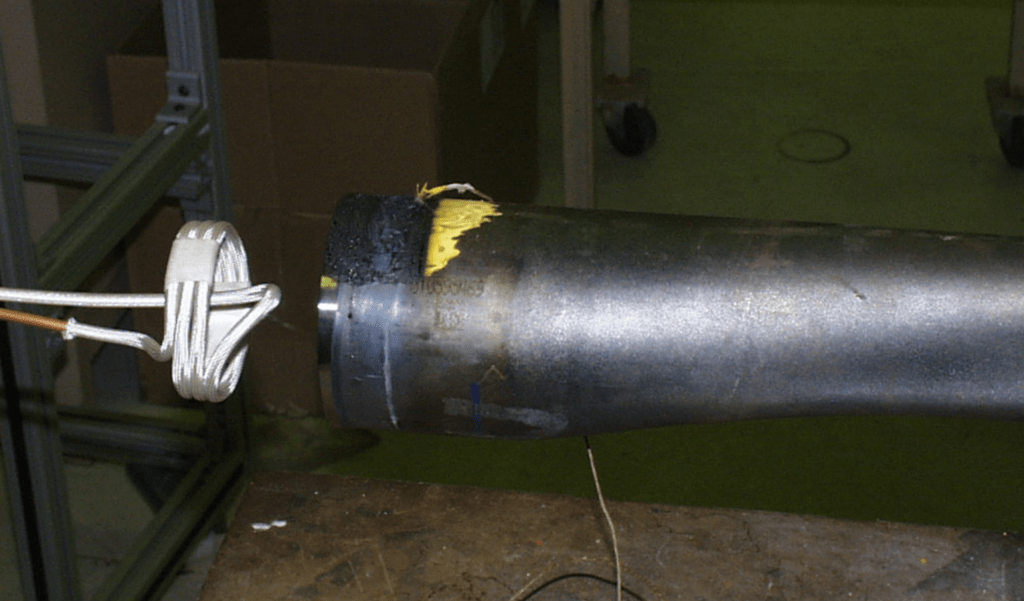

Material: Customer supplied 3.6” (91 mm) O.D. steel axle

Material: Customer supplied 3.6” (91 mm) O.D. steel axle

Frequency: 121 kHz

Equipment: DW-HF-45kW 50-150 kHz induction heating system equipped with a remote heat station containing eight 1.0 μF capacitors in series parallel

– A single position internal bore induction heating coil designed and developed specifically for this application.

Induction Preheating Process: The steel axel was painted with temperature indicating paint and a thermocouple was attached to the part. The induction heating coil was placed inside the steel axel and the power supply was turned on. This approach enabled the weld line to be heated to 662 ºF (350 ºC) within five seconds as desired by the client. The power supply is capable of being programmed to turn off after the desired heating time – five seconds in this case. Then, the coil can be moved to the second weld line, and the third weld line.

Induction Preheating Process: The steel axel was painted with temperature indicating paint and a thermocouple was attached to the part. The induction heating coil was placed inside the steel axel and the power supply was turned on. This approach enabled the weld line to be heated to 662 ºF (350 ºC) within five seconds as desired by the client. The power supply is capable of being programmed to turn off after the desired heating time – five seconds in this case. Then, the coil can be moved to the second weld line, and the third weld line.

Results/Benefits Process: With the coil being inside the axle, it does not get in the way, and it can then easily be moved to the next weld line

– Speed: Induction and the proposed process enables the weld lines to be heated to temperature within the targeted

time

– Free lab testing: This is a new project for the client, and HLQ Lab Service Request testing enabled the client to

test their application and an innovative approach was designed