-

1/5

-

2/5

-

3/5

-

4/5

-

5/5

Induction thermal stripping paint and coating process

Induction Thermal Removal Paint and Coating with Safe and Effective Solution For Paint and Coating Removal Needs

Induction thermal stripping paint and coating is a process that uses heat to remove paint from surfaces. It is a highly efficient and environmentally friendly method of paint removal that has become increasingly popular in recent years. In this article, we will explore the benefits of induction thermal stripping paint and how it works.

What is Induction Thermal Stripping Paint/costing?

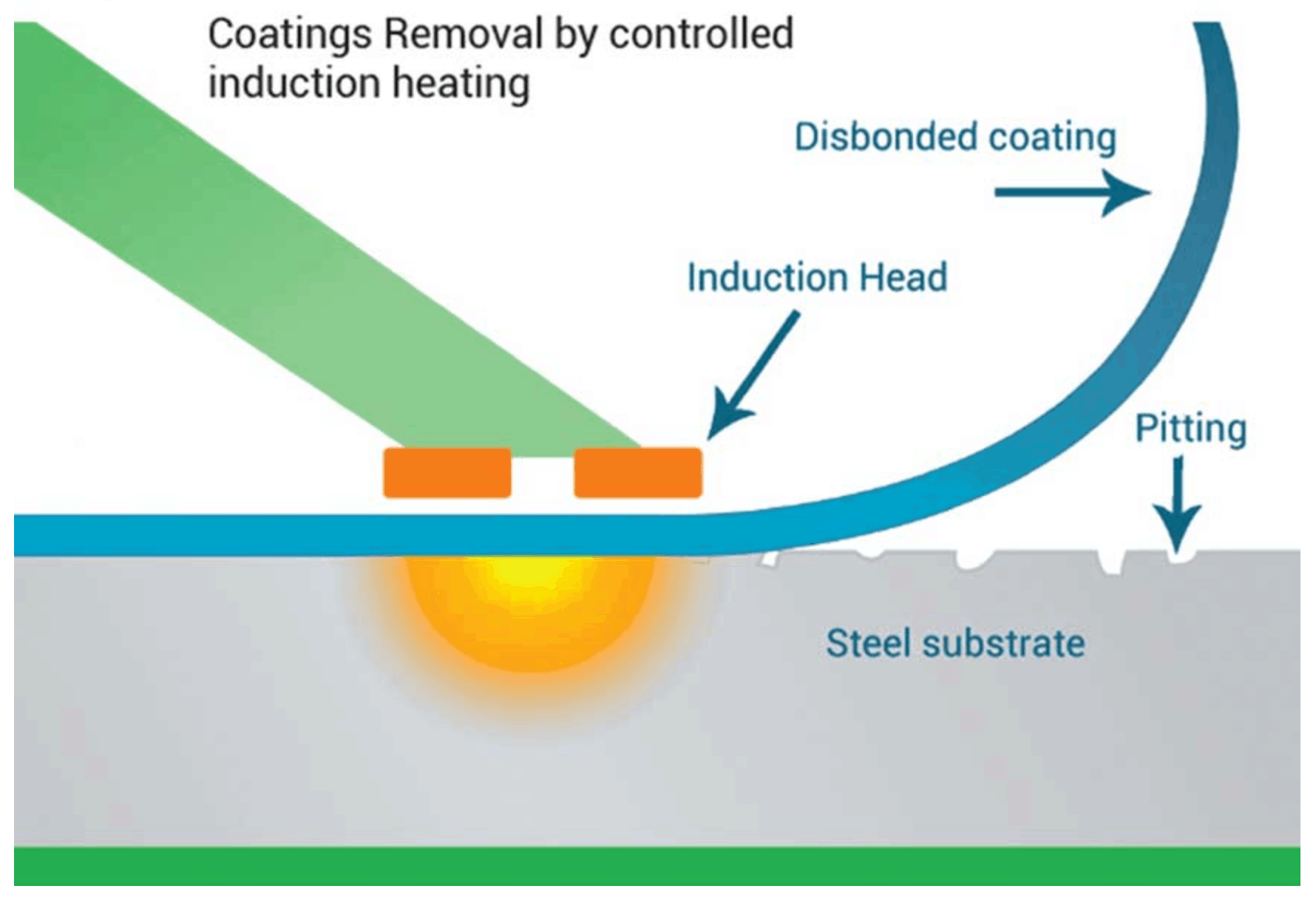

Induction thermal stripping paint is a process that uses heat to remove paint from surfaces. It works by inducing an electrical current in the metal substrate, which creates heat. The heat then softens the paint, causing it to bubble and peel away from the surface. Once the paint has been removed, the surface can be cleaned and prepared for a new coat of paint.

Benefits of Induction Thermal Stripping Paint:

1. Environmentally Friendly: Induction thermal stripping paint is an environmentally friendly method of paint removal. Unlike traditional methods, such as sandblasting or chemical stripping, induction thermal stripping paint does not produce harmful chemicals or dust.

2. Cost-Effective: Induction thermal stripping paint is a cost-effective method of paint removal. It is faster and more efficient than traditional methods, which means that it requires less labor and time.

3. Safe: Induction thermal stripping paint is a safe method of paint removal. It does not produce sparks or flames, which means that it can be used in areas where traditional methods would be unsafe.

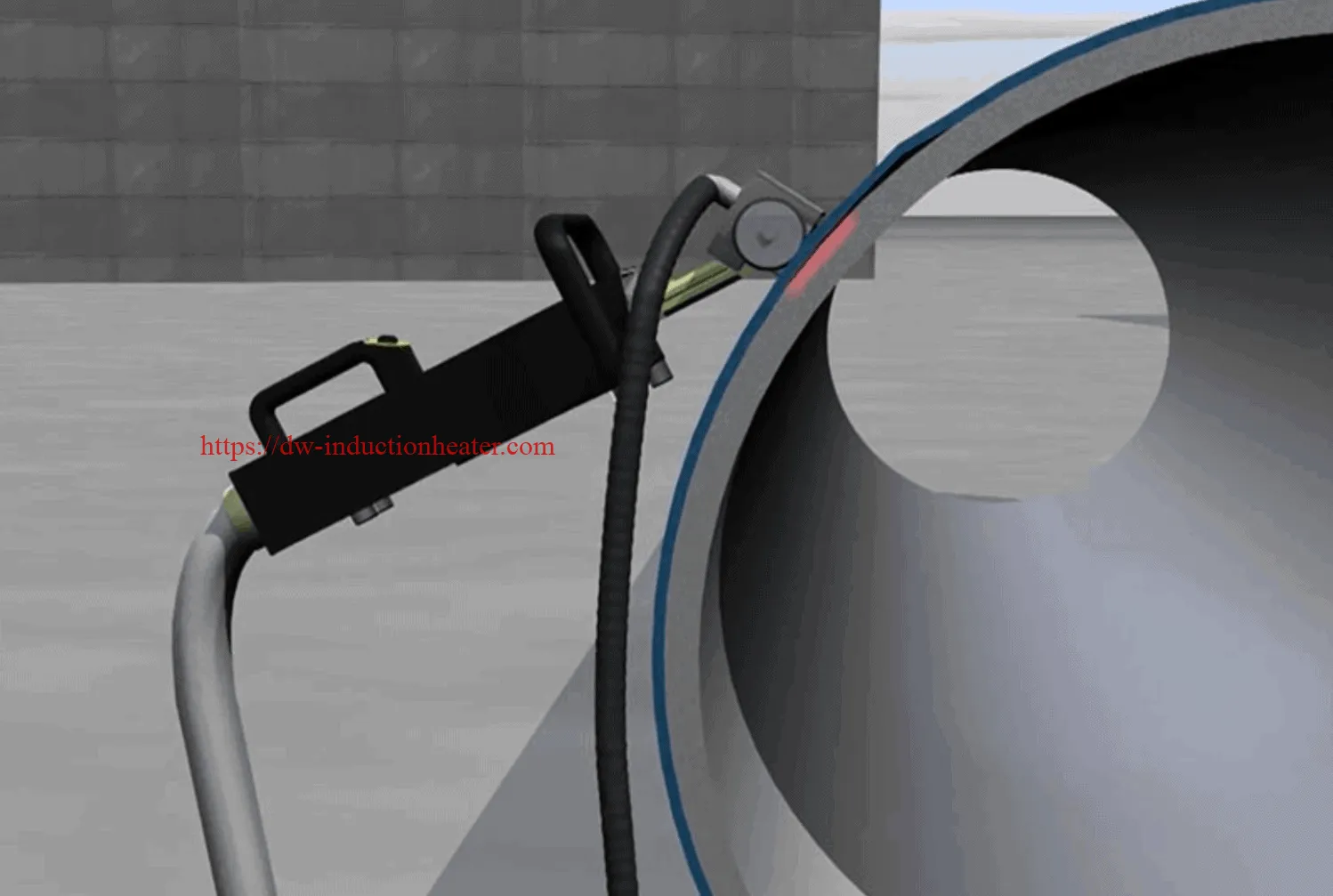

4. Versatile: Induction thermal stripping paint can be used on a wide range of surfaces, including steel, aluminum, and other metals. It can also be used on surfaces that are difficult to reach with traditional methods.

How Induction Thermal Stripping Paint Works:

Induction thermal stripping paint works by inducing an electrical current in the metal substrate. This is done using an induction coil, which is placed near the surface to be stripped. The coil is connected to a high-frequency power supply, which generates an alternating current. When the current passes through the metal substrate, it creates heat. The heat softens the paint, causing it to bubble and peel away from the surface. The paint can then be scraped away using a scraper or wire brush.

The process can be controlled by adjusting the frequency and power of the induction coil. This allows the operator to tailor the process to the specific needs of the job.

Conclusion:

Induction thermal stripping paint is a highly efficient and environmentally friendly method of paint removal. It is cost-effective, safe, and versatile, making it an ideal choice for a wide range of applications. If you are looking for a method of paint removal that is fast, efficient, and safe, then induction thermal stripping paint is definitely worth considering.