-

1/4

-

2/4

-

3/4

Induction Hardening

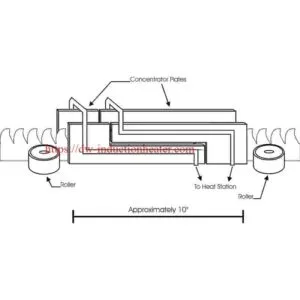

Induction hardening Treatment is favored for parts that are subject to heavy loading. Typical applications include axles, saw blades, shafts, stampings, spindles, gears and most symmetrical parts. Induction hardening treatment is widely used for surface hardening steel, but can be used with other materials as well.Steel hardening consists of heating the material to a temperature over 723ºC (austenitic temperature) and then cooling the steel quickly, often with a quench of industrial water. The aim of this induction heating application is to transform the structure of the steel in order to increase its hardness, its yield strength,and its breaking tension. The steels that are normally hardened with induction heating contain from 0.3% to 0.7% carbon.

we have many induction hardening solutions in the following areas:

1. Induction hardening treatment of engine parts such as valves, crankshafts, camshafts, connection rods and starter rings

2. Induction hardening treatment of transmission parts, for example CV joints, tulips and axle shafts

3. Induction hardening treatment of suspension parts such as shock absorber rods, springs and suspension arms

4. Induction hardening treatment of parts for automatic and manual gear gearboxes, for example rings, selector shafts and sun gears

5. Induction hardening treatment of clutch springs and brake pads

Induction hardening is a metal heat treatment process that offers a controllable and localized method of heat without contact to the metal parts or components being heated. The heat is generated by inducing an electric current to flow in the object to be heated. This provides a very economical, targeted and rapid heat treating of conductive materials.

Carbon steels

Alloy steels

Stainless steels

Powder metal

Cast iron

Copper

Aluminum