-

1/4

-

2/4

-

3/4

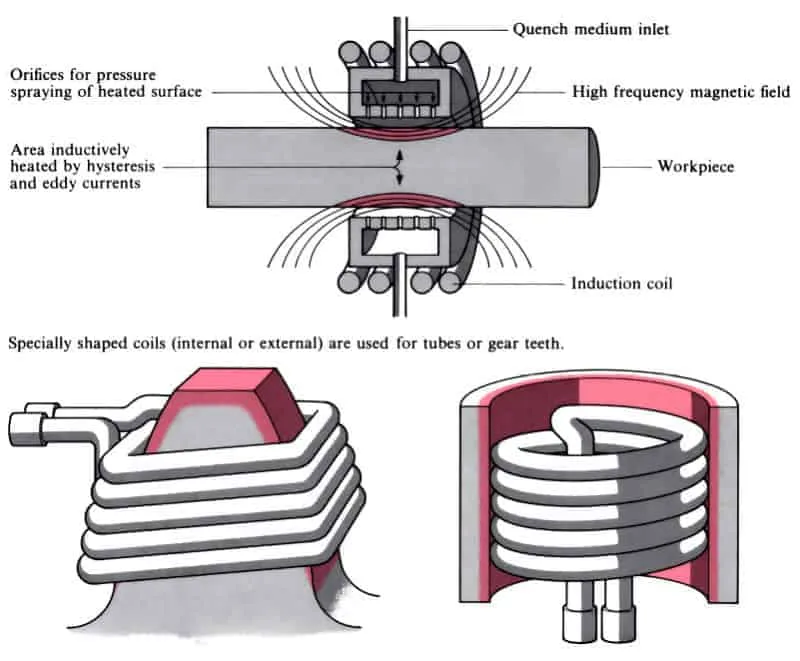

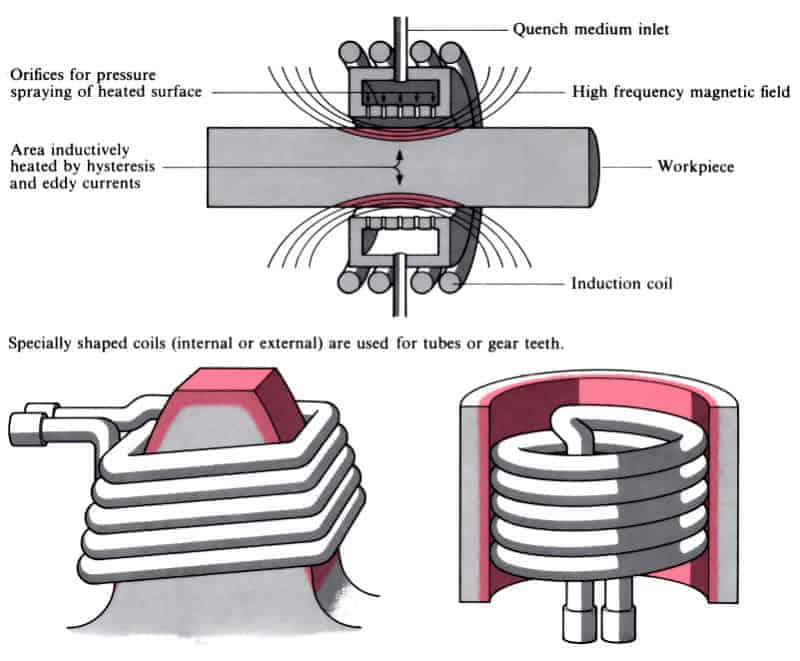

Induction surface hardening steel fitting

Induction Surface Hardening steel fitting to 1600 ºF (871 ºC) for a hardening application

Induction Surface hardening steel fitting for a machined parts manufacturer is usually carried out by induction heating.The main technical parameters are surface hardness,local hardness and effective hardened layer depth.

Material : Steel fittings (0.75”/19mm diameter)

Temperature: 1600 ºF (871 ºC)

Frequency: 368 kHz

Equipment:

–DW-UHF-10kW induction heating system equipped with a remote heat station containing two 1.0 μF capacitors

-A three-turn pancake helical induction heating coil designed and developed specifically for this application

The induction heating coil design enabled the part to be raised into the heating coil from the bottom. The design was also made to ensure it will work well within the customer’s current setup. Initial testing took place with temperature-indicating paints to evaluate the uniformity of the heating pattern and the heating speed. With a good heating pattern achieved, samples were processed at time intervals of 1.0, 1.25 and 1.5 seconds. The samples were dropped into a water quench following heating to conclude the hardening process.

Results/Benefits

Speed: The fitting was heated in well under two seconds

Efficiency: Induction uses less energy than competitive heating methods

Footprint/Design: Induction heating can be implemented while taking up modest floor space, plus the coil design fits within the customer’s operational arrangement