-

1/3

-

2/3

Induction Hardening Cast Iron

Induction Hardening Cast Iron With High Frequency Induction Heating Machinery

Objective Heat cast iron pulleys to 1600ºF(871.1ºC) in order to achieve a hardness of 55 Rockwell C.

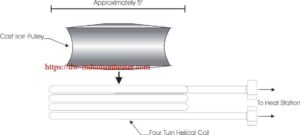

Material Ductile Iron Pulleys measuring 3 1/2″(88.9mm) OD and 2″ (50.8mm) high.

Temperature 1600ºF (871.1ºC)

Frequency 164 kHz

Equipment • DW-UHF-10kW induction heating system equipped with a remote workhead containing eight (8) capacitors totaling 0.66 μF

• An induction heating coil designed and developed specifically for this application.

Process A four turn helical coil is used to heat the cast iron pulley for 2 minutes and 45 seconds to reach the required 1600ºF (871.1ºC) Immediately following, the pulley is quenched in an agitated water bath to achieve the desired hardness.

Results/Benefits Induction heating provides:

• Increased production

• Repeatable, non-contact and energy efficient heat

• Precise heating