-

1/4

-

2/4

-

3/4

-

4/4

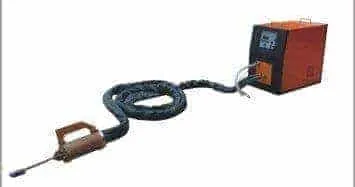

Handheld Induction Brazing Heater

Handheld&Portable Induction Brazing Heater

| Items | DWS-10 | DWS-30 | DWS-60 | DWS-100 | |

| Max. input power | 10KW | 30KW | 60KW | 100KW | |

| Input voltage | 3P×380V,50 or 60HZ | ||||

| Generator size | L50×W30×H45 | 57L×32W×71H | 70L×40W×103.5H | 56L×80W×180H | |

| Generator weight | 40KG | 47KG | 120KG | 150KG | |

| Heating head size | Φ5.5×22L | Ф8×18.5 | Φ12×25L | Ф16×25 | |

| Heating head weight | 1.5KG | 3.1KG | 4.5KG | 8KG | |

| Cable length | 3~8 meters according to order | ||||

| Cooling desire | >0.3MPa,> 5L/Min | >0.3MPa,> 15L/Min | >0.3MPa,> 30L/Min | ≥0.3MPa ≥30L/min | |

Applications:

Brazing small parts, selective heat treatment, and induction heating in areas requiring a smaller, moveable unit. Used for induction brazing on site such as the induction brazing of copper cable connectors, copper joints in the air conditioner, copper connectors of the transformer and so on.

Characteristics:

- By special design, the portable induction heating head is small sized and only weights 1.5 to 8 KG, it is especially suitable for the operation on working site when the heated parts can not be moved.

- The handheld induction heater is characterized with high reliability and high quality while the IGBT power module and our third generation inverting technology is adopted in the induction heating machine.

- The induction heating coil will be designed according to your requests.

A handheld induction brazing heater is a versatile, efficient, and portable tool designed to utilize induction heating technology for brazing applications. These devices are widely used in industries such as HVAC, plumbing, automotive, and electronics, where precision and speed are critical. Below is a concise overview of what a handheld induction brazing heater is, how it works, and its key benefits:

How a Handheld Induction Brazing Heater Works

A handheld induction brazing heater relies on electromagnetic induction to heat conductive metals. When a high-frequency alternating current passes through a coil, it generates an electromagnetic field that induces an electric current (eddy currents) in the metal. The resistance of the material to these currents produces heat, melting the filler material without direct contact, resulting in strong and precise joints.

Key Features of Handheld Induction Brazing Heaters

- Portability: Compact and lightweight, these heaters can be easily carried and operated in tight or remote spaces.

- Precision: The concentrated electromagnetic field heats only the target area, reducing the risk of damaging nearby components.

- Energy Efficiency: Induction heating systems are known for their rapid heat generation and energy conservation, cutting down on operational costs.

- Eco-Friendliness: Induction heating minimizes harmful emissions compared to flame-based methods.

- Adaptability: Designed to work with various metals, including steel, copper, aluminum, and brass, making them ideal for diverse applications.

Advantages Over Traditional Heating Methods

- No Open Flames: Reduces fire risks and ensures safety in hazardous environments.

- Fast Heating Time: Achieves target temperature quickly, shortening the brazing process.

- Consistent Results: Offers repeatable and uniform heating, leading to high-quality joints.

- Low Maintenance: Minimal wear and tear as there are no direct contact components subject to thermal stress.

Choosing the Right Handheld Induction Brazing Heater

To select the best handheld induction brazing heater, consider:

- Power Output: Ensure the wattage aligns with the requirements of the materials and applications.

- Frequency Range: A higher frequency is ideal for smaller, detailed work, while lower frequencies suit larger parts.

- Portability Features: Look for lightweight, ergonomic designs for ease of transport and operation.

- Cooling Systems: Efficient cooling mechanisms prevent overheating during extended use.

- Customization Options: Flexible coils and interchangeable parts for various use cases.

Frequently Asked Questions (FAQs)

1.

What materials can be brazed with a handheld induction brazing heater?

Handheld induction brazing heaters work well with metals such as copper, stainless steel, aluminum, brass, and other alloys.

2.

Is induction brazing faster than flame brazing?

Yes, induction brazing is significantly faster, often heating in seconds, which makes it ideal for high-volume production.

3.

Are handheld induction brazing heaters safe to use?

Yes, these heaters are safer than traditional flame-based systems because they do not produce open flames or harmful emissions.

4.

Can handheld induction brazing heaters be used outdoors?

Yes, their portability allows for outdoor use, provided there is access to power and the environmental conditions are suitable.

5.

What power supply is needed for a handheld induction brazing heater?

Most handheld units operate on standard AC power (110V or 220V). However, industrial versions may require higher power levels.

Summary

Handheld induction brazing heaters are a revolutionary tool that combines portability, precision, and energy efficiency, making them an indispensable part of modern manufacturing and repair industries. They replace traditional flame-based methods with a safer, faster, and more sustainable solution, offering unparalleled benefits in a broad range of applications. Whether you’re an HVAC technician, automotive repair specialist, or manufacturing professional, investing in a handheld induction brazing heater can significantly improve workflow efficiency and product quality.