-

1/5

-

2/5

-

3/5

-

4/5

Electromagnetic Induction Water Heaters

Electromagnetic Induction Water Heaters: The Future of Efficient Water Heating Technology

The global push toward energy efficiency and sustainable heating solutions has spotlighted electromagnetic induction water heaters as a revolutionary alternative to conventional water heating systems. These advanced systems leverage the principles of electromagnetic induction to generate heat directly within water, offering unprecedented efficiency, reduced energy consumption, and minimal environmental impact. This comprehensive guide explores the technology behind induction water heaters, their technical specifications, performance metrics, and the compelling advantages that make them increasingly popular in both industrial and commercial applications.

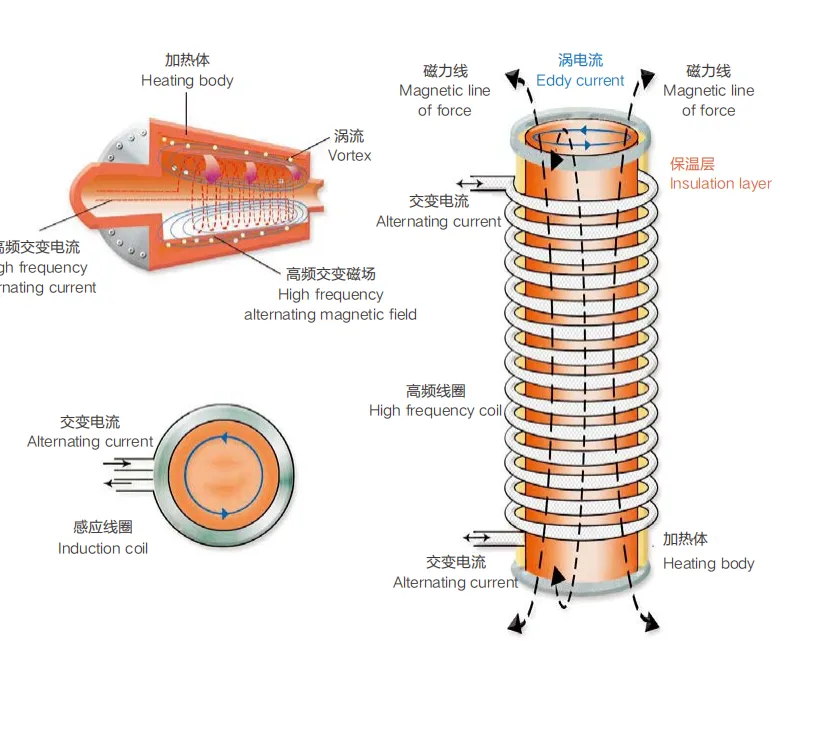

How Electromagnetic Induction Water Heating Works

Electromagnetic induction water heaters operate on Michael Faraday’s principle of electromagnetic induction. When alternating current flows through a coil (inductor), it creates a fluctuating magnetic field. This magnetic field induces eddy currents in conductive materials, generating heat through electrical resistance. In water heating applications, specially designed induction coils transfer energy directly to water passing through the system, achieving remarkable heating efficiency of up to 99%.

Unlike conventional heating methods that rely on heat transfer through surfaces, induction heating generates heat directly within the water, eliminating thermal losses associated with traditional systems. This direct energy conversion results in faster heating times, precise temperature control, and significantly reduced energy consumption.

Technical Parameters and Specifications

Electromagnetic induction water heaters are available in various power capacities to suit different applications. The following tables provide detailed technical specifications across different power ranges:

Table 1: Small to Medium Capacity Induction Water Heaters (30kW-200kW)

| Parameter | 30kW Model | 60kW Model | 100kW Model | 150kW Model | 200kW Model |

|---|---|---|---|---|---|

| Input Voltage | 380V±10%, 3-phase | 380V±10%, 3-phase | 380V±10%, 3-phase | 380V±10%, 3-phase | 380V±10%, 3-phase |

| Frequency | 50/60Hz | 50/60Hz | 50/60Hz | 50/60Hz | 50/60Hz |

| Power Factor | ≥0.95 | ≥0.95 | ≥0.96 | ≥0.96 | ≥0.97 |

| Heating Efficiency | 98% | 98% | 98.5% | 99% | 99% |

| Water Flow Rate | 0.5-1.5 m³/h | 1.0-3.0 m³/h | 1.7-5.0 m³/h | 2.5-7.5 m³/h | 3.4-10.0 m³/h |

| Max Water Temp | 95°C | 95°C | 98°C | 98°C | 98°C |

| Temp Control Precision | ±1°C | ±1°C | ±0.8°C | ±0.8°C | ±0.5°C |

| Working Pressure | ≤0.6MPa | ≤0.6MPa | ≤0.8MPa | ≤0.8MPa | ≤1.0MPa |

| Cooling Method | Water-cooled | Water-cooled | Water-cooled | Water-cooled | Water-cooled |

| Protection Grade | IP54 | IP54 | IP54 | IP54 | IP54 |

Table 2: High Capacity Industrial Induction Water Heaters (250kW-800kW)

| Parameter | 250kW Model | 350kW Model | 500kW Model | 650kW Model | 800kW Model |

|---|---|---|---|---|---|

| Input Voltage | 380V±10%, 3-phase | 380V±10%, 3-phase | 380V±10%, 3-phase | 380V/480V, 3-phase | 380V/480V, 3-phase |

| Frequency | 50/60Hz | 50/60Hz | 50/60Hz | 50/60Hz | 50/60Hz |

| Power Factor | ≥0.97 | ≥0.97 | ≥0.98 | ≥0.98 | ≥0.98 |

| Heating Efficiency | 99% | 99% | 99% | 99% | 99% |

| Water Flow Rate | 4.3-12.5 m³/h | 6.0-17.5 m³/h | 8.5-25.0 m³/h | 11.0-32.5 m³/h | 13.6-40.0 m³/h |

| Max Water Temp | 98°C | 98°C | 99°C | 99°C | 99°C |

| Temp Control Precision | ±0.5°C | ±0.5°C | ±0.3°C | ±0.3°C | ±0.3°C |

| Working Pressure | ≤1.0MPa | ≤1.0MPa | ≤1.2MPa | ≤1.2MPa | ≤1.6MPa |

| Cooling Method | Water-cooled | Water-cooled | Water-cooled | Water-cooled | Water-cooled |

| Protection Grade | IP54 | IP54 | IP54 | IP54 | IP54 |

| IGBT Protection | Advanced | Advanced | Advanced | Advanced | Advanced |

| Control System | PLC + HMI | PLC + HMI | PLC + HMI | PLC + HMI | PLC + HMI |

Performance Analysis and Efficiency Metrics

Energy Efficiency Analysis

Electromagnetic induction water heaters demonstrate remarkable energy efficiency advantages over conventional heating systems. The following data analysis highlights the comparative performance:

| Heating Method | Energy Efficiency | Heat-up Time (50°C rise) | Annual Energy Consumption* |

|---|---|---|---|

| Induction Water Heater | 95-99% | 60-90 seconds | 100% (baseline) |

| Electric Resistance Heater | 70-80% | 180-240 seconds | 125-135% |

| Gas Water Heater | 55-75% | 240-300 seconds | 130-150% |

| Oil-fired Boiler | 50-70% | 300-360 seconds | 140-160% |

*For equivalent heating capacity, normalized to induction heater consumption

Temperature Rise Performance

The following graph data demonstrates the rapid temperature rise capabilities of induction water heaters across different power ratings:

| Power Rating | Temp Rise (°C/min) at 50% Flow | Temp Rise (°C/min) at 75% Flow | Temp Rise (°C/min) at 100% Flow |

|---|---|---|---|

| 30kW | 50-55 | 35-40 | 25-30 |

| 100kW | 52-58 | 37-42 | 27-32 |

| 250kW | 55-60 | 38-43 | 28-33 |

| 500kW | 58-63 | 40-45 | 30-35 |

| 800kW | 60-65 | 42-47 | 32-37 |

Return on Investment Analysis

Based on operational data from industrial installations, electromagnetic induction water heaters demonstrate compelling ROI metrics:

| Parameter | Small Scale (30-100kW) | Medium Scale (100-350kW) | Large Scale (350-800kW) |

|---|---|---|---|

| Initial Investment Premium* | +30-40% | +25-35% | +20-30% |

| Annual Energy Savings | 20-30% | 25-35% | 30-40% |

| Maintenance Cost Reduction | 40-50% | 45-55% | 50-60% |

| Typical Payback Period | 1.5-2.5 years | 1.2-2.0 years | 0.8-1.5 years |

| Lifetime Cost Advantage | 30-40% | 35-45% | 40-50% |

*Compared to conventional heating systems of equivalent capacity

Key Advantages of Electromagnetic Induction Water Heaters

1. Unparalleled Energy Efficiency

With efficiency ratings of up to 99%, electromagnetic induction water heaters convert virtually all electrical energy into heat, minimizing waste and reducing operational costs. The direct energy transfer mechanism eliminates intermediate heat exchanges that typically result in thermal losses.

2. Precise Temperature Control

Advanced digital control systems enable temperature precision within ±0.3°C, ensuring consistent water temperature for critical processes. This precision is particularly valuable in industrial applications where temperature stability directly impacts product quality.

3. Rapid Heating Response

Induction heating systems can reach target temperatures within seconds, eliminating warm-up periods associated with conventional systems. This responsiveness allows for on-demand heating, reducing standby energy consumption.

4. Compact Design and Space Efficiency

Modern electromagnetic induction water heaters require up to 70% less installation space compared to traditional boiler systems, offering significant advantages for facilities with limited space.

5. Environmental Benefits

Induction water heaters produce zero direct emissions, supporting carbon reduction goals. Their high efficiency translates to reduced energy consumption and lower greenhouse gas emissions from power generation.

6. Reduced Maintenance Requirements

The absence of combustion components, heating elements, and complex mechanical systems results in minimal maintenance needs and extended operational life. Most systems require only annual inspection rather than regular component replacement.

Applications Across Industries

Electromagnetic induction water heaters are highly efficient and versatile devices that leverage the principles of electromagnetic induction to heat water. Their applications span a variety of sectors due to their efficiency, reliability, and compact design. Here are some of the key applications:

- Domestic Hot Water Supply

- Residential tankless water heaters that use electromagnetic induction for on-demand, efficient hot water with minimal heat loss.

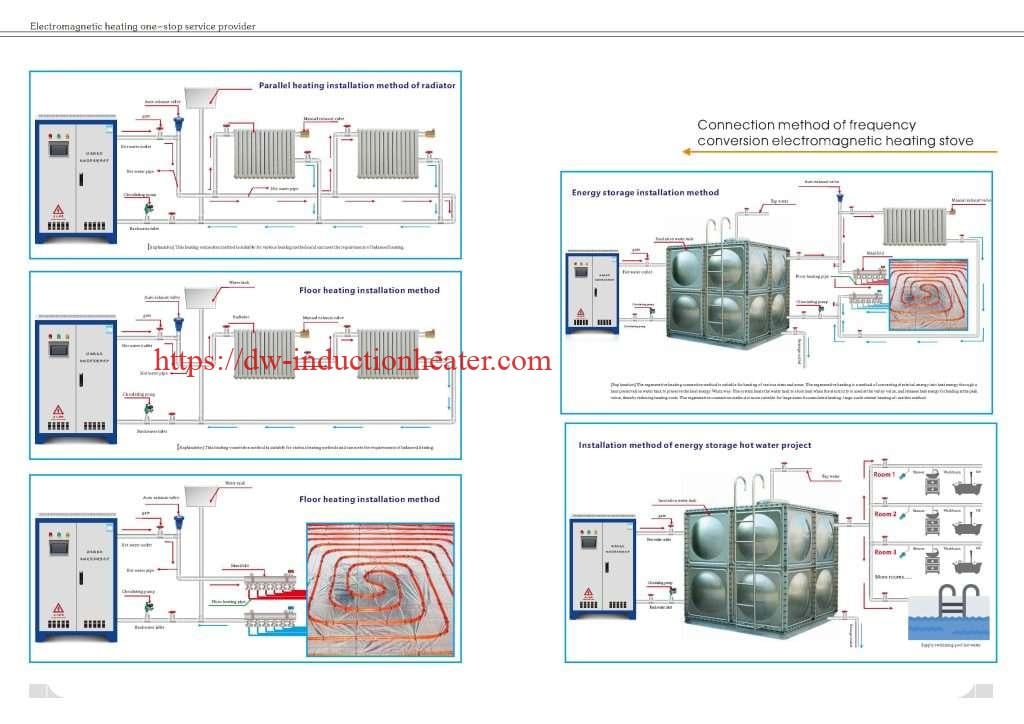

- Central Heating and HVAC Systems

- Integration into home or commercial heating systems, providing a rapid heating source for radiators and water-based HVAC solutions.

- Commercial Kitchens and Food Service

- Rapid water heating for dishwashers, sanitizers, and other commercial appliances where quick, precise temperature control is essential.

- Laundry and Textile Facilities

- Industrial-scale induction heaters for hot water supply in laundromats and textile dyeing processes, boosting efficiency while reducing downtime.

- Industrial Process Heating

- Automotive and Car Wash Facilities

- Supplying on-demand hot water for vehicle cleaning and detailing services, taking advantage of efficient energy use and fast temperature ramp-up.

- Sterilization and Sanitation

- Hospitals, research laboratories, and veterinary clinics often require reliable high-temperature water for sterilizers, autoclaves, or cleaning systems.

- Hot Water Supply for Swimming Pools and Spas

- Using electromagnetic induction heaters in conjunction with pumps and filtration systems for faster heating and precise temperature maintenance.

- Remote or Off-Grid Locations

- Potentially paired with renewable energy sources (solar, wind) for efficient on-demand water heating in cabins, remote healthcare centers, or mobile installations.

- Heat Recovery and Circulation Systems

- Integration with heat exchangers or closed-loop systems where induction-based heating complements or replaces traditional boiler elements.

Across all these applications, the main advantages of electromagnetic induction water heaters include rapid heating speeds, high energy efficiency, improved safety (no open flame), and reduced scaling issues compared to conventional resistance heating systems.

Future Trends and Innovations

The electromagnetic induction water heating market continues to evolve with several emerging trends:

- Smart Integration: Modern systems increasingly feature IoT connectivity, allowing remote monitoring, predictive maintenance, and integration with building management systems.

- Hybrid Systems: Manufacturers are developing hybrid solutions that combine induction heating with renewable energy sources like solar thermal and heat pumps.

- Advanced Materials: Research into specialized magnetic materials promises to further enhance efficiency and reduce manufacturing costs.

- Miniaturization: Compact designs are expanding applications into residential markets previously dominated by conventional water heaters.

Conclusion

Electromagnetic induction water heaters represent a significant advancement in water heating technology, offering substantial improvements in efficiency, control, and environmental performance. The comprehensive technical data presented demonstrates their superior performance metrics across multiple parameters, making them an increasingly attractive option for forward-thinking businesses seeking to optimize energy usage while reducing operational costs.

As energy costs continue to rise and environmental regulations become more stringent, the adoption of electromagnetic induction water heating technology provides a strategic advantage for industries requiring reliable, efficient, and precise water heating solutions. With rapid return on investment and compelling lifetime cost advantages, these systems are positioned to become the standard for industrial and commercial water heating applications in the coming decade.