-

1/6

-

2/6

-

3/6

-

4/6

-

5/6

CNC Induction Horizontal Hardening Scanners-Quenching Surface Machines

What is an Induction Horizontal Hardening Scanner?

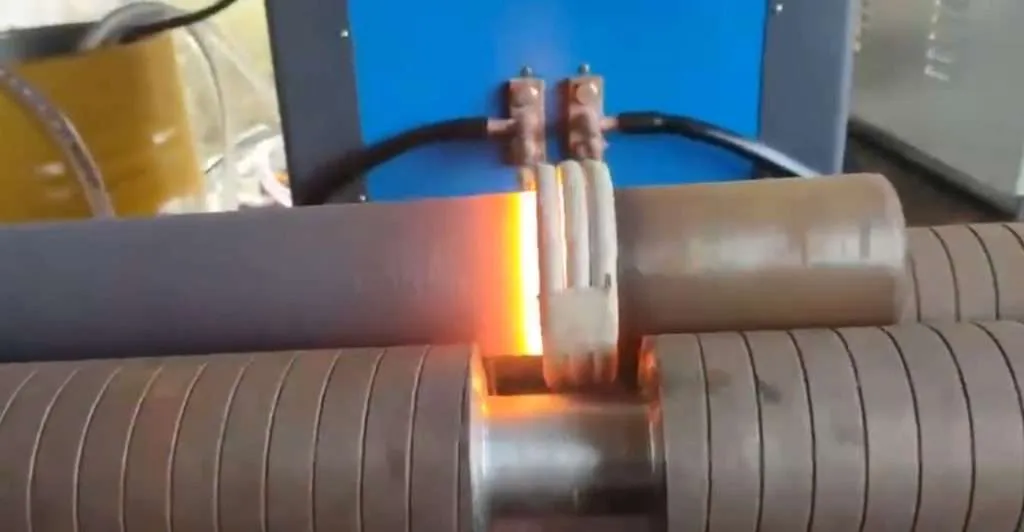

An induction horizontal hardening scanner is a machine used in the metalworking industry to harden the surface of metal parts. It uses electromagnetic induction to heat the metal, followed by rapid cooling, to improve its hardness and durability.

The induction horizontal hardening scanner represents a pivotal innovation in the realm of metallurgical engineering and heat treatment processes. This article provides an in-depth examination of the induction horizontal hardening scanner’s design, operational principles, key applications, and the advancements it brings to the industry. By leveraging electromagnetic induction, this state-of-the-art equipment enables precise control over the induction hardening of various metallic components, enhancing their wear resistance and extending their service life.

How does an Induction Horizontal Hardening Scanner work?

The scanner generates an electromagnetic field through an induction coil, heating the metal part to a specific temperature. The part is then quickly cooled, often with water or another quenching medium, to harden the surface.

What are the benefits of using Induction Horizontal Hardening Scanners?

What are the benefits of using Induction Horizontal Hardening Scanners?

These scanners offer precision in hardening specific areas of a part, consistency in treatment results, increased production efficiency due to faster processing times, and energy savings compared to traditional hardening methods.

- Which industries commonly use Induction Horizontal Hardening Scanners? Industries that commonly use these scanners include automotive, aerospace, tool manufacturing, and any sector requiring improved wear resistance and durability of metal components.

Can Induction Horizontal Hardening Scanners treat all types of metals? While they are versatile, their effectiveness can vary depending on the metal’s properties, such as its electrical conductivity and magnetic permeability. Commonly treated metals include steel and its alloys, but the suitability for other metals should be evaluated based on specific requirements.

Can Induction Horizontal Hardening Scanners treat all types of metals? While they are versatile, their effectiveness can vary depending on the metal’s properties, such as its electrical conductivity and magnetic permeability. Commonly treated metals include steel and its alloys, but the suitability for other metals should be evaluated based on specific requirements.

Design and Operational Principles:

The induction horizontal hardening scanner embodies a complex assembly of inductive coils, quenching mechanisms, and precise control systems. It operates on the principle of electromagnetic induction to generate eddy currents and localized heat within the metallic workpiece. The induced heat is meticulously controlled, both spatially and temporally, to achieve the desired hardening effect. Quenching mediums—typically water, oil, or polymer solutions—are subsequently applied to rapidly cool the heated areas, locking in the hardness. The horizontal configuration of the scanner allows for the accommodation of elongated workpieces, promoting a uniform hardening process and enabling the treatment of parts with various geometries. The precision of the scanner is augmented by advanced sensors and control software, which monitor and adjust parameters in real-time to ensure consistent quality.

Technical Details of CNC Horizontal Induction Hardening Machine Tools (It can be customized for you):

Technical Details of CNC Horizontal Induction Hardening Machine Tools (It can be customized for you):

|

Model

|

LP-SK-600 | LP-SK-1200 | LP-SK-2000 | LP-SK-3000 |

|

Max Holding Length(mm)

|

600 | 1200 | 2000 | 3000 |

| Max Hardening Length(mm) | 580 | 1180 | 1980 | 2980 |

| Max Swing Diameter(mm) | ≤500 | ≤500 | ≤500 | ≤500 |

| Work-piece Moving Speed(mm/s) | 20~60 | 20~60 | 20~60 | 20~60 |

| Rotation Speed(r/min) | 40~150 | 30~150 | 25~125 | 25~125 |

| Tip Moving Speed(mm/min) | 480 | 480 | 480 | 480 |

| Work-piece Weight(kg) | ≤50 | ≤100 | ≤800 | ≤1200 |

| Input Voltage(V) | 3 phase 380V | 3 phase 380V | 3 phase 380V | 3 phase 380V |

| Total Motor Power(KW) | 1.1 | 1.2 | 2 | 2.5 |

| Hardening Quantity Each Time | Single/Double | Single | Single | Single |

The induction horizontal hardening scanners stand as a testament to the relentless pursuit of technological excellence in materials engineering. By providing a highly controlled, efficient, and versatile approach to metal hardening, it plays a crucial role in enhancing the performance and durability of critical components across various industries. As the technology continues to evolve, it will undoubtedly remain at the forefront of manufacturing innovation, pushing the boundaries of what is possible in the heat treatment landscape.