-

1/6

-

2/6

-

3/6

-

4/6

-

5/6

-

6/6

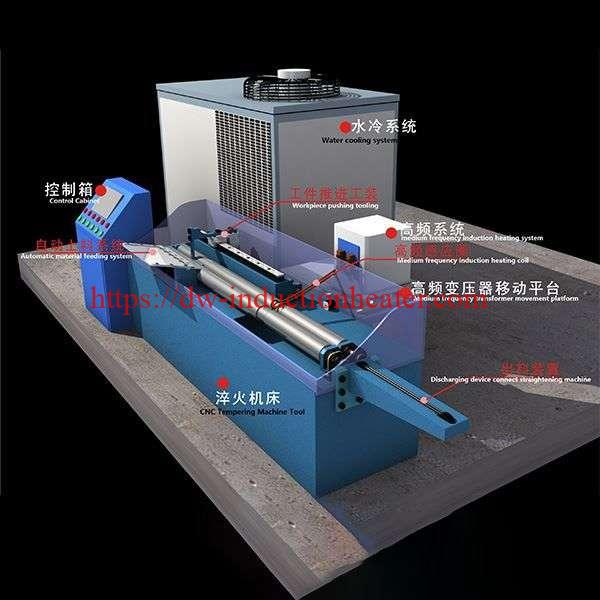

CNC Horizontal Induction Hardening Machine Tools

CNC Horizontal Induction Hardening Machine Tools are advanced equipment used for the induction hardening process. These machines use computer numerical control (CNC) technology to precisely control the induction hardening process, resulting in consistent and high-quality hardened parts.

The horizontal design of these machines allows for easy loading and unloading of workpieces, making them suitable for mass production and high-volume manufacturing environments. The CNC control system enables operators to program specific hardening parameters such as heating temperature, heating time, and quenching process, ensuring precise and repeatable results.

Induction hardening is a heat treatment process that involves heating the surface of a metal part using electromagnetic induction, followed by rapid quenching to achieve a hardened surface layer. This process is commonly used in the automotive, aerospace, and manufacturing industries to improve the wear resistance and durability of components such as gears, shafts, and bearings.

Technical Details of CNC Horizontal Induction Hardening Machine Tools (It can be customized for you):

|

Model

|

LP-SK-600 | LP-SK-1200 | LP-SK-2000 | LP-SK-3000 |

|

Max Holding Length(mm)

|

600 | 1200 | 2000 | 3000 |

| Max Hardening Length(mm) | 580 | 1180 | 1980 | 2980 |

| Max Swing Diameter(mm) | ≤500 | ≤500 | ≤500 | ≤500 |

| Work-piece Moving Speed(mm/s) | 20~60 | 20~60 | 20~60 | 20~60 |

| Rotation Speed(r/min) | 40~150 | 30~150 | 25~125 | 25~125 |

| Tip Moving Speed(mm/min) | 480 | 480 | 480 | 480 |

| Work-piece Weight(kg) | ≤50 | ≤100 | ≤800 | ≤1200 |

| Input Voltage(V) | 3 phase 380V | 3 phase 380V | 3 phase 380V | 3 phase 380V |

| Total Motor Power(KW) | 1.1 | 1.2 | 2 | 2.5 |

| Hardening Quantity Each Time | Single/Double | Single | Single | Single |

Applications:

1.Suitable for quenching and tempering of various workpieces, such as induction quenching of crankshafts, gears, rollers, guide rails and other parts.

2.It has the functions of continuous quenching, simultaneous quenching, segmented continuous quenching, segmented simultaneous quenching, etc.

3.The CNC system or PLC and frequency conversion speed regulation system are used to realize workpiece positioning and scanning, and the PLC and induction power supply are connected to realize fully automated production.

Overall, CNC Horizontal Induction Hardening Machine Tools are essential equipment for achieving precise and efficient induction hardening of metal parts in modern manufacturing operations.