-

1/2

Annealing Titanium Fasteners With Induction

Annealing Titanium Fasteners With Induction Heater

Objective Heating a titanium fastener to 1100-1450ºF (593-788ºC) for an annealing process.

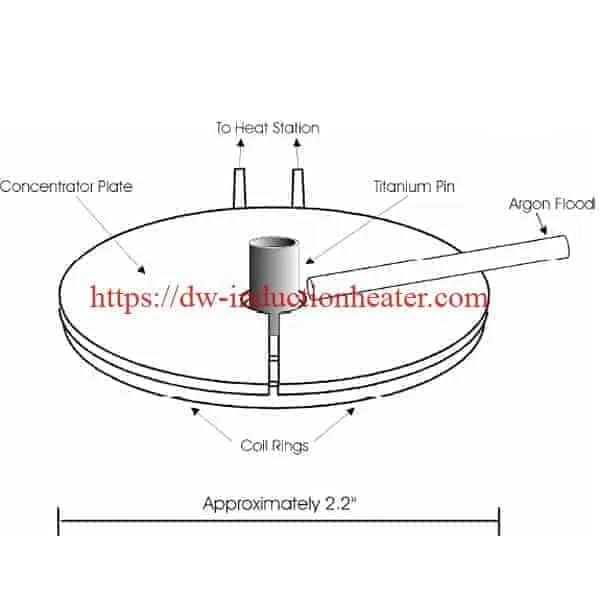

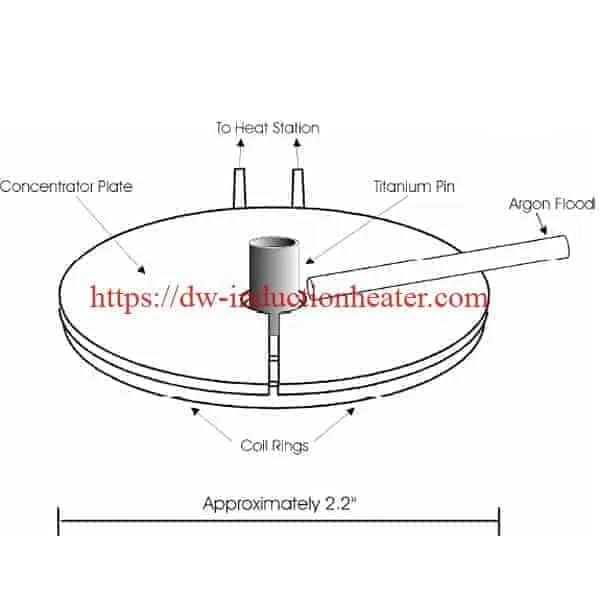

Material 0.06” (1.5mm) high zone on a titanium fastener measuring 0.163-0.375” (4.14-9.52mm) in diameter and 0.5-3.0” (12.7- 76.2mm) in length

Temperature 1100-1450ºF (593-788ºC)

Frequency 150 kHz

Equipment •DW-UHF-20kW induction heating system, equipped with a remote workhead containing one 0.66μF capacitor.

• An induction heating coil designed and developed specifically for this application.

Process A three turn concentrator plate coil is used to heat the fastener for 0.2 seconds. This is an automated process that includes robotic placement of parts in the coil from a bowl fed track while Argon gas is flooded across the part to prevent oxidation. The parts are processed at a rate of 1000 parts per minute.

Results/Benefits Induction heating provides:

• Can be incorporated easily with pick and place robotics.

• Flameless process.

• Heating is limited to the specific area.