-

1/3

-

2/3

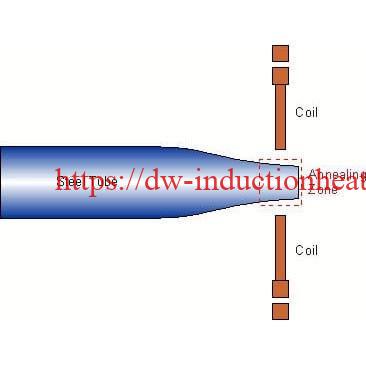

Induction Annealing Steel Tube

Induction Annealing Steel Tube-Copper Tubing-Pipe With High Frequency Heating Units

Objective To heat steel tubes to 2000 ºF (1093 ºC) in an inert atmosphere

Material 0.1” (2.54mm) diameter stainless steel tube

Temperature 2000 ºF

Frequency 323 kHz

Equipment • DW-UHF-6kW induction heating system, equipped with a remote workhead containing one 1.0μF capacitor.

• An induction heating coil designed and developed specifically for this application.

Process A two turn concentrator coil is used to heat the stainless steel tube. The annealing process takes place in an inert atmosphere to prevent oxidation. The stainless steel tube is placed in the inert atmosphere and heats to 2000 ºF (1093 ºC) in 15 seconds to achieve the desired characteristics.

Results/Benefits Induction heating provides:

• Fast, controllable process

• Heat very small areas within precise production tolerances

• Hands-free heating that involves no operator skill for manufacturing

• Even distribution of heating