-

1/10

-

2/10

-

3/10

-

4/10

-

5/10

-

6/10

-

7/10

-

8/10

-

9/10

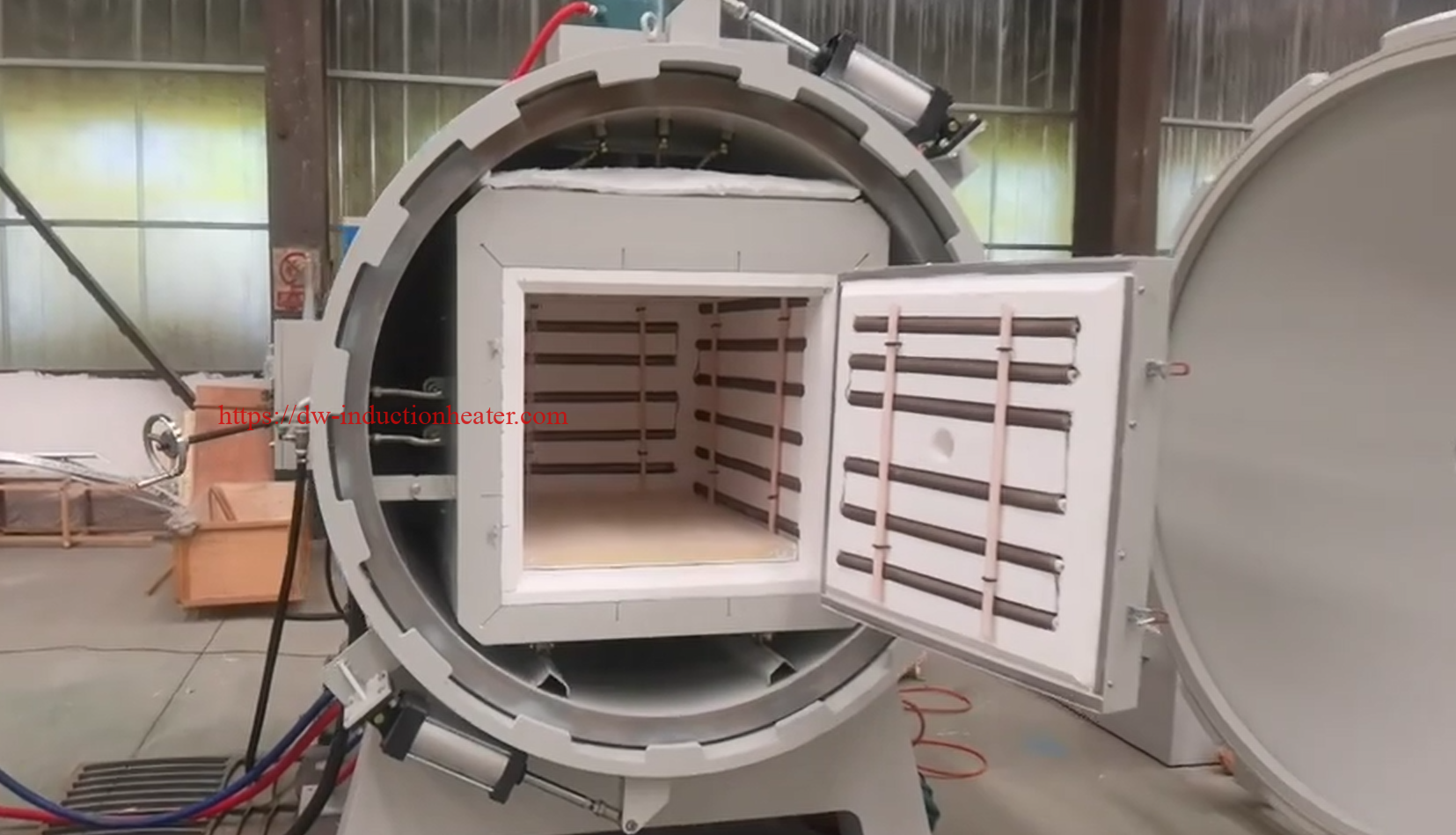

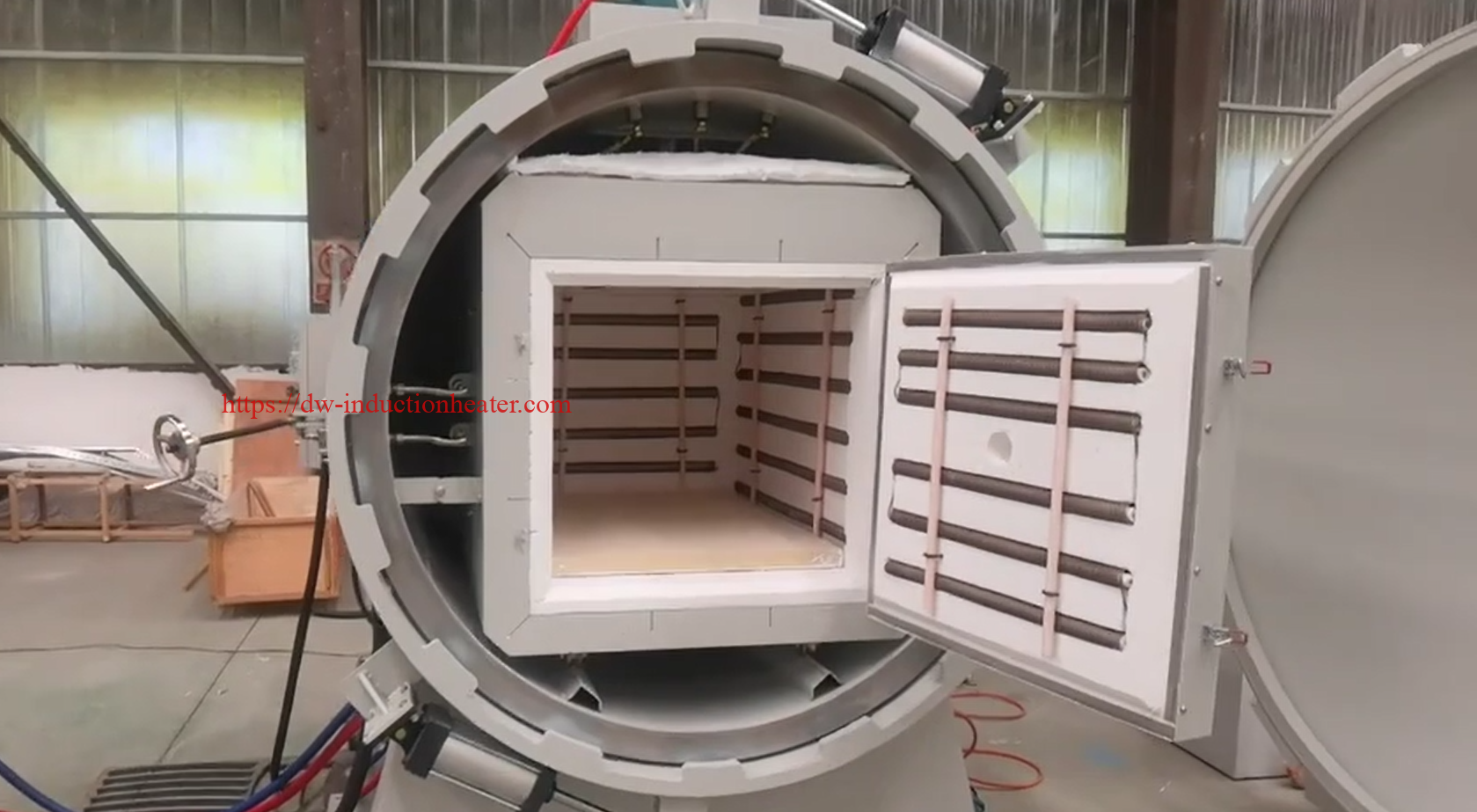

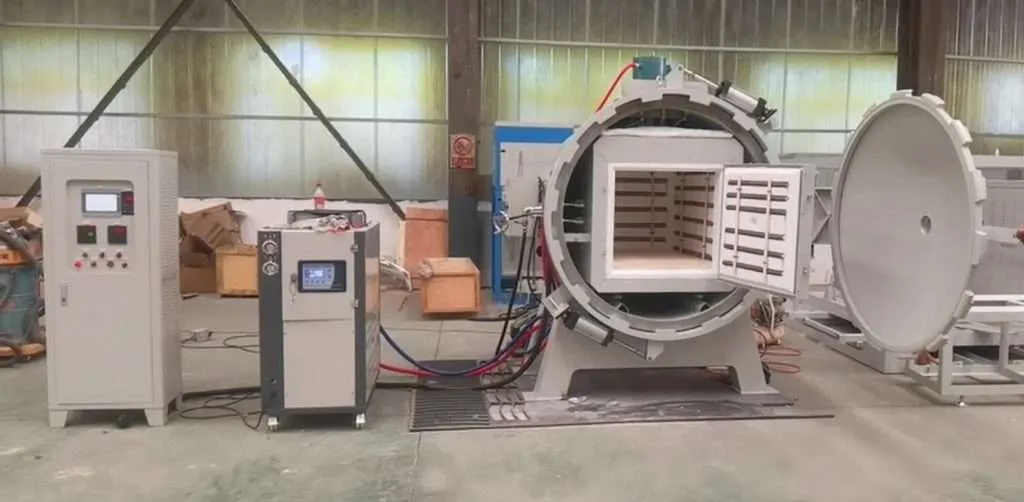

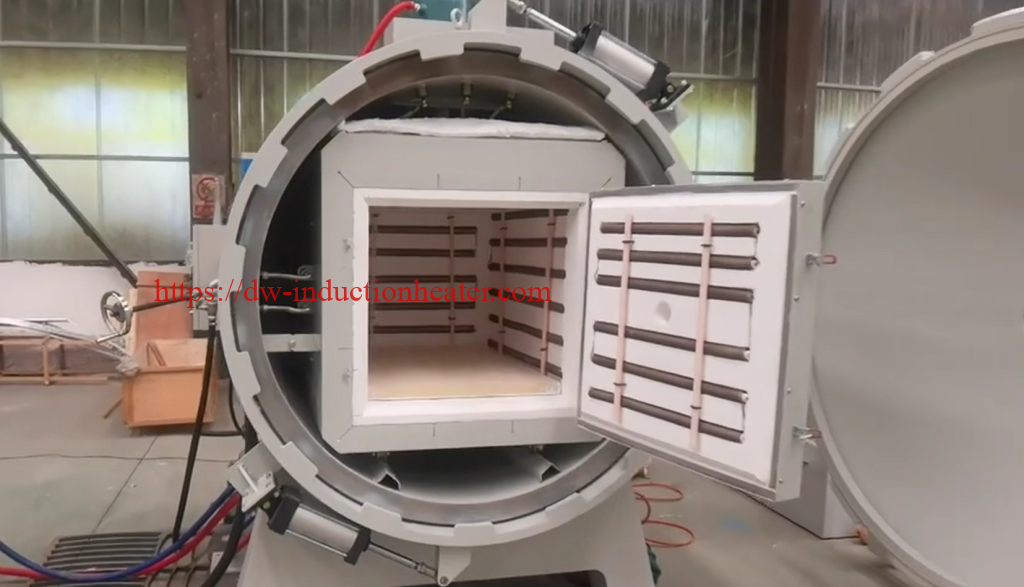

Vacuum Atmosphere Heat Treatment Furnace with hot air circulation

The Vacuum Atmosphere Heat Treatment Furnace has emerged as a critical technology in modern material science, offering unparalleled control over environmental conditions during the heat treatment process. This article delves into the intricacies of this system, exploring its design, operation, benefits, and applications in the industry.

The Vacuum Atmosphere Heat Treatment Furnace represents a significant leap forward, providing a contaminant-free environment that allows for precise control of temperature and atmospheric conditions. This technology has become instrumental in various industries that require high-performance materials, including aerospace, automotive, and tool-making sectors.

| Items | Parameter |

| Temperature | 1000 ℃ |

| Model | GWL-1000VSF |

| Furnace size (mm) | Depth×width×height: 600×600×900 |

| power | 45KW |

| VoltageAC | 380V |

| Maximum power | The design power is 75KW, and the actual power used is within about 85%. The power can be automatically adjusted according to different heating processes. |

| Temperature control accuracy | ±1 ℃ (Integrated circuit control, no overshoot) |

| The control range is | 50 to 1000 degrees |

| Temperature field uniformity in the furnace | ±5 ℃ |

| Temperature measuring element and temperature measuring range | Thermocouple K type, temperature measurement range 0-1320 degrees |

| Heating rate | The heating rate can be adjusted freely, and the adjustment range is: the fastest heating rate is 15 degrees per minute (15 degrees/min), and the slowest heating rate is 1 degree per hour (1 degree/h). |

| Heating element | Beijing Shougang HRE high temperature alloy resistance wire (containing molybdenum ) is used and wound into a spiral spring shape |

| Heating element installation location | It is evenly distributed around the inside of the furnace + at the bottom, and uses five-sided heating. The heating body generates heat evenly, and the temperature field in the furnace is uniform and the effect is good. |

| Furnace body | The furnace body is processed by CNC machine tools, and is made by polishing, grinding, pickling, phosphating, spraying plastic powder, high-temperature baking, etc. It has two-color matching, a novel and beautiful appearance, and has anti-oxidation, acid and alkali resistance, corrosion resistance, and corrosion resistance. High temperature, easy to clean and other advantages |

| Furnace structure | The electric furnace body adopts the internationally advanced air-cooled double-layer furnace structure. The effective air-cooling guide partition circulates cold air throughout the furnace shell, and finally cools the conductive sheets of the heating element and then discharges the furnace body, avoiding high-temperature oxidation of the conductive sheets of the heating element. ; Ensure a good working environment |

| Observation window | The furnace door is equipped with an observation window |

| Furnace door opening method | The furnace door opening method is side door opening. |

| Furnace door locked | Use pneumatic locking furnace door |

| Furnace shell temperature | for long-term use , and the outer shell temperature is less than 45 degrees. |

| Hot air stirring | The function of hot air stirring: There is an air leaf on the top of the furnace. Through the rotation of the air leaf , the temperature of the space inside the furnace is evenly distributed, so as to achieve the purpose of uniform temperature in the furnace. |

| Mixing blade | 310S stainless steel, operating temperature below 1050 degrees |

| Stirring motor and speed | The mixing motor is water-cooled, and the speed is infinitely adjusted through a frequency converter. Power 3KW |

| Forced cooling system | The furnace is equipped with a stainless steel cooling coil, which can be filled with circulating cold zone water to accelerate heat dissipation in the furnace, increase the cooling speed, and improve the working efficiency of the equipment. The circulating cold water system adopts a closed circulation system, which is composed of a closed water cooler, control valves and stainless steel pipes, which can effectively improve equipment utilization. The cooling speed can be guaranteed to be ≮ 35 ℃ /h, which can meet the demand of opening the furnace door when the furnace temperature drops to 70 ℃ within 10 hours . |

| Refrigerator | 3P |

| Vacuum pump | Adopt two-stage rotary vane vacuum pump 70L/s |

| Vacuum degree | -0.1Mpa. |

| Pressure resistant | The steel plate of the electric furnace furnace is 6-20mm thick, double-sided welded, and can withstand positive pressure of 0.1Mpa. |

| Air valve | Imported stainless steel valves |

| Pressure detection | A positive pressure and negative pressure double indicator pointer pressure gauge

A positive pressure and negative pressure dual indication digital pressure gauge |

| Barometer | Two float flow meters |

| air intake | 2 |

| exhaust vent | 1 |

| Seals | The seal is made of high temperature resistant silicone rubber ring (temperature resistant 260 degrees-350 degrees) |

| pressure protection | In order to prevent the furnace exhaust port from being closed, the exhaust port is blocked, and the furnace pressure is too high, this system is specially designed. The principle is: the electric contact pressure gauge or pressure sensor obtains the signal, drives the control module to close the electromagnetic air inlet valve, and starts the electromagnetic exhaust valve. The air valve and alarm release the pressure from the exhaust port, and the sound and light alarm buzzer sounds the alarm. To protect the normal operation of the electric furnace |

| accessible atmosphere | Hydrogen, nitrogen, argon, carbon monoxide, oxygen, etc. |

| Refractory materials | The furnace lining is made of vacuum-formed high-purity alumina poly-light materials. Lightweight hollow spherical alumina plates are used for easy-to-touch material handling and load-bearing locations (furnace mouth and furnace bottom). It has high operating temperature, low heat storage, and is resistant to rapid heat and rapid cooling. , no cracks, no slag, good thermal insulation performance (the energy saving effect is more than 80% of the old electric furnace) |

| Insulation Materials | It adopts three layers of insulation, namely: aluminum silicate fiber board, alumina fiber board, and alumina (polycrystalline) fiber board. The energy saving effect is more than 80% of that of the old electric furnace. |

| Protect | Using an integrated modular control unit, the control accuracy is accurate, and dual-loop control and dual-loop protection are designed, with overshoot, overshoot, undershoot, segment coupling, phase loss, overvoltage, overcurrent, overtemperature, and current feedback , soft start and other protection |

| control | Adopting closed-loop technology thyristor module trigger control, phase-shift trigger control method, the output voltage, current or power is continuously adjustable, with the characteristics of constant voltage, constant current or constant power; the current loop is the inner loop and the voltage loop is the outer loop. When a load is suddenly added or the load current exceeds the current limit value, the output current of the voltage regulator is limited to the rated current range to ensure the normal operation of the output and voltage regulator; at the same time, the voltage loop also participates in the adjustment, so that the output current of the voltage regulator is It is limited to the rated current range and maintains constant output current and voltage with sufficient adjustment margin; thereby protecting the heating element from the impact of excessive current and voltage, and achieving safe and reliable control effect and control accuracy. |

| Display parameters | Temperature, temperature segment number, period of time, remaining time, output power percentage, voltage, current, etc. |

| button | The imported buttons have a service life of more than 100,000 times and are equipped with LED indicators. |

| Temperature curve setting | Using 7-inch touch screen paperless recorder |

| temperature control | Adopt intelligent temperature controller |

| Multiple curve input | 30-segment program control function, you can input settings: one curve is 30 segments, two curves are 14 segments/strip, three curves are 9 segments/segment, five curves are 5 segments/strip; multiple curves can be input at the same time, and they can be used at will transfer. |

| Communication Interface | RS485 RS232 USB |

| Alarm and protection | Install an audible and visual ultra-high temperature alarm and an automatic power-off device when opening the door |

| Automatic fire extinguishing system | The equipment is equipped with a flame detection alarm and fire extinguishing system. When a fire occurs in the furnace through the remote sensing sensing system, an alarm signal will be sent out to prompt the operator to confirm the fire and whether to turn on the powder fire extinguishing system. Compressed fire extinguishing dry powder can be charged into the furnace. Perform fire extinguishing treatment on the sintered specimens. |

| Warranty scope and period | The electric stove has a one-year free warranty, but the heating element is not under warranty (it will be replaced free of charge if it is damaged due to natural damage within three months). |

| Random spare parts | Two heating elements, two sets of rods , a pair of crucible pliers , and a pair of high-temperature gloves |

| Packing List | One electric furnace, two heating elements, two sets of rods , one crucible pliers , one pair of high-temperature gloves, one instruction manual, one certificate of conformity, one acceptance report (factory inspection report), and one sales delivery note. |

Design and Operation:

The design of a Vacuum Atmosphere Heat Treatment Furnace is centered around its ability to create and maintain a vacuum or controlled atmosphere. The furnace typically comprises a robust, sealed chamber constructed from stainless steel or other high-temperature resistant alloys. The chamber is equipped with heating elements capable of reaching high temperatures, often in the range of 1200°C to 1800°C, depending on the application.

The heat treatment process begins with the evacuation of air from the chamber to achieve the desired vacuum level, using high-performance vacuum pumps. Alternatively, the chamber can be backfilled with an inert gas, such as argon or nitrogen, to create a specific atmosphere. The material to be treated is then heated at a controlled rate to the target temperature, held for a predetermined time, and subsequently cooled, either rapidly or slowly, based on the required material properties.

Benefits of Vacuum Atmosphere Heat Treatment:

The use of a vacuum or controlled atmosphere during heat treatment offers several benefits over traditional methods:

1. Reduced Oxidation and Decarburization:

By removing oxygen from the environment, the risk of oxidation and decarburization is minimized, preserving the material’s surface integrity and overall quality.

2. Enhanced Mechanical Properties:

Vacuum heat treatment can lead to more uniform microstructures, resulting in improved mechanical properties such as hardness, toughness, and fatigue resistance.

3. Clean and Bright Finishes:

Materials processed in a vacuum atmosphere often have a cleaner and brighter finish, reducing the need for additional surface treatments.

4. Precise Control:

The ability to control the atmosphere and temperature profiles with high accuracy allows for the fine-tuning of material properties to meet specific requirements.

Applications:

The versatility of Vacuum Atmosphere Heat Treatment Furnaces has led to their adoption in various applications:

1. Aerospace Components:

The aerospace industry requires components that can withstand extreme conditions. Vacuum heat treated parts offer the necessary strength and durability without compromising weight.

2. Automotive Parts:

High-performance automotive parts, such as gears and bearings, benefit from the wear resistance and strength provided by vacuum heat treatment.

3. Tool and Die Making:

Tools and dies require exceptional hardness and dimensional stability, which vacuum heat treatment can achieve while maintaining tight tolerances.

4. Medical Devices:

The biocompatibility and performance of medical implants and devices are enhanced through vacuum heat treatment processes that ensure clean and sterile surfaces.

Conclusion:

The adoption of Vacuum Atmosphere Heat Treatment Furnaces has become indispensable in the pursuit of advanced materials. Its ability to precisely control environmental conditions during heat treatment translates into superior material properties and performance. As industries continue to demand higher quality and more specialized materials, the role of vacuum heat treatment technology will undoubtedly expand, fostering further innovations and applications in the field of material science.

[pdf-embedder url=”https://dw-inductionheater.com/wp-content/uploads/2024/03/Vacuum-Atmosphere-Furnace-En.pdf” title=”Vacuum Atmosphere Furnace En”]