-

1/3

-

2/3

Induction Heating Steel Rods

Induction Heating Steel Rods Simultaneously for a Molding Process With High Frequency Heating Equipment

Objective Heat eight steel rods simultaneously to 212°F (100°C) for a molding operation.

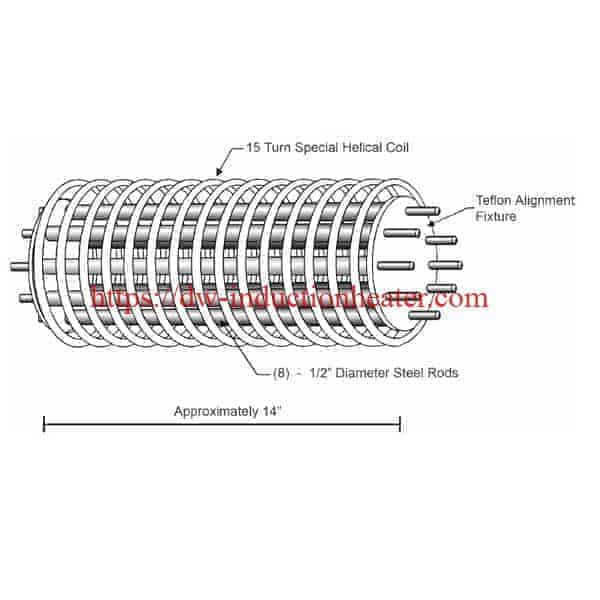

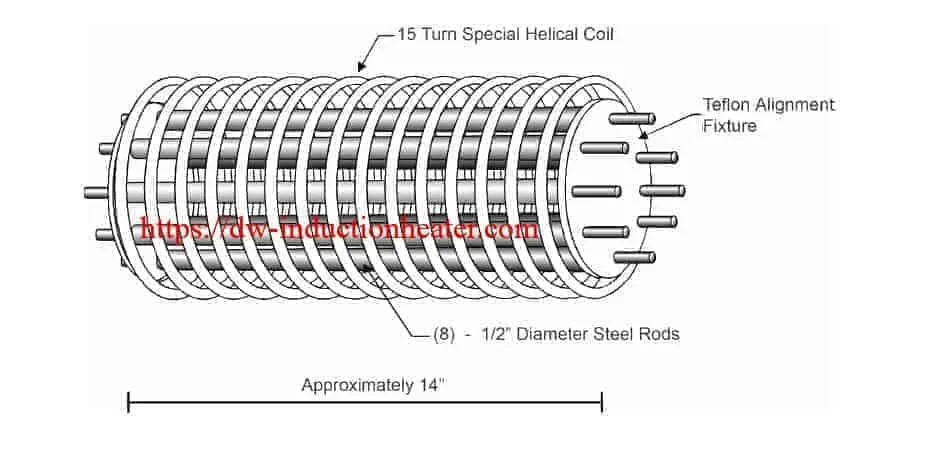

Material 8 Steel Rods measuring 1/2″ (12.7mm) in diameter and 14″ (355.6mm) long held in place by 2.5” (63.5mm) diameter Teflon end plates.

Temperature 212°F (100°C)

Frequency 20 kHz

Equipment • DW-MF-25kW power supply kW induction heating system equipped with a remote workhead containing one capacitor equaling 0.66 μF

• An induction heating coil designed and developed specifically for this application.

Process A fifteen turn helical coil is used to heat the stainless steel rods simultaneously for 45 seconds to reach 212°F (100°C). Teflon end plates are used to hold the rods in place.

Results/Benefits Induction heating provides:

• Uniform heating without rotation of rod capsule

• Decrease in energy consumption

• Hands free operation