-

1/2

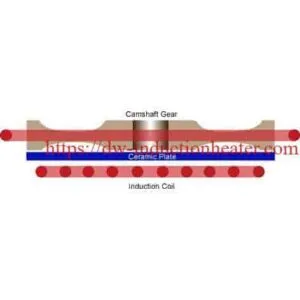

Induction Heating Shrink Steel Flange

Induction Heating Shrink Steel Flange With IGBT Heating Fitting Units

Objective To heat steel flange for heat shrink application. Reaching the desired temperature results in adequate expansion to allow for placing of the flange over a graphite seal.

Material Graphite seal 1” (25.4mm) diameter steel flange

Temperature indicating paint

Temperature 700°F (370°C)

Frequency 206 kHz

Equipment DW-UHF-4.5kW, 150-400 kHz solid state induction power supply, equipped with a remote heat station containing one 0.66 μF capacitor.

A three-turn helical induction heating coil designed and developed specifically for this application.

Process The part is placed inside the induction heating coil and power is supplied to the coil until the steel heats. This is done to determine the time-to-temperature and the heating pattern on the part.

The composite assembly heats uniformly and reaches 700 F (370°C) in 10-12 seconds.

Results/Benefits When the steel reaches the desired temperature it easily slips on to the graphite.

Benefits include uniform, precise heat with quick heat up cycles.