-

1/3

-

2/3

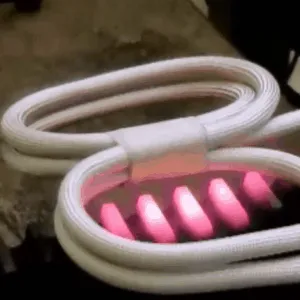

Induction hardening Jaw Teeth of Carbon Steel

Category: Induction Hardening

Tags: hardening, hardening carbon steel, hardening jaw teeth, hardening jaw teeth induction, high frequency, high frequency hardening, high frequency hardening teeth, high frequency induction hardening, induction hardening, induction hardening steel teeth, induction hardening teeth

High frequency induction hardening Jaw Teeth of Carbon Steel surface process

Objective

Successful hardening of the jaw teeth using induction.

Equipment

DW-UHF-6KW-I handheld induction hardening machine

HLQ custom coil

Materials

Carbon steel jaw teeth supplied by the customer

Key Parameters

Power: 4 kW

Temperature: Approximately 1526° F (830° C)

Time: 10-15 sec

Process:

- A test coil was custom made for the application.

- The sample was fixed in position inside of the coil.

- Induction heating was applied to the teeth.

- The temperature of the sample was monitored during heating.

- Heat was applied until the hardening temperature was reached.

Results:

- System managed to achieve its maximum power.

- The tooth was heated to 830°C in 12 sec.

- 930°C was reached in 20 sec.

- The Curie point (around 770°C) is reached in 5 sec.

Conclusions:

- System configuration –DW-UHF-6KW-I is suitable for the process.

- Classic coil is also suitable for this application.

Recommendations:

- Automation of the process can be achieved by moving either the HS with coil or the jaw in vertical direction.

- Proper cooling systems have to be chosen. Cooling capacity – at least 4kW. Water-to-air system can be used, but it depends on the ambient operational temperature.