-

1/4

-

2/4

-

3/4

-

4/4

Induction Brazing Copper Tube

Induction Brazing Copper Tube With High Frequency RF Heating Equipment

Research Objective

To heat a copper tube assembly in an inert atmosphere to 1450°F within 45 seconds for brazing without flux or acid wash clean-up.

Parts & Materials Description

Copper tube assembly, temperature sensing paint, braze pre-forms

Temperature Required

1450°F

Induction Heating Equipment

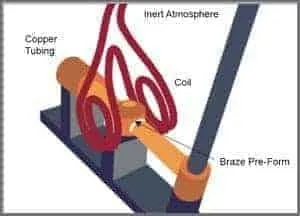

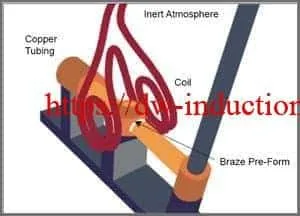

DW-UHF-10kW Induction Heating power supply, remote heat station with two 1.25 microfarad capacitors (cumulative capacitance of 0.625 mfd.) and a specially-designed inductor (coil)

Operating Frequency

400kHz

Heating Procedure

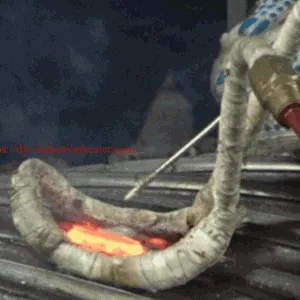

The testing was done in the ABS Mark 2 containing a mixture of 95% Argon and 5% Hydrogen gas. A specially- designed, four-turn split helical inductor was used to provide optimal heating to the joint area of the tube assembly. After initial tests were conducted with bare parts and temperature sensing paints to establish time-to-temperature and heating profiles, a temperature of 1450°F was reached in 45 seconds to melt the brazing pre-forms.

Conclusion

Successful results were achieved at 1450°F within 45 seconds. Since the heat conducts through the tube assembly, subsequent joints on the same assembly would require less time. Brazing copper tube assemblies is an excellent application for induction heating.