-

1/5

-

2/5

-

3/5

-

4/5

electromagnetic induction fluid liquid boiler | induction thermal oil heating boiler

The Ultimate Guide to electromagnetic induction fluid liquid boiler: Benefits, Applications and Maintenance.

electromagnetic induction fluid liquid boiler are an efficient and eco-friendly way to heat commercial and industrial spaces. With their numerous benefits and applications, it’s no wonder that more and more businesses are turning to this technology for their heating needs. In this article, we will explore the world of induction thermal oil boilers, discussing the benefits they offer, the wide variety of applications they can be used for, and the best practices for maintenance.

electromagnetic induction fluid liquid boiler are an efficient and eco-friendly way to heat commercial and industrial spaces. With their numerous benefits and applications, it’s no wonder that more and more businesses are turning to this technology for their heating needs. In this article, we will explore the world of induction thermal oil boilers, discussing the benefits they offer, the wide variety of applications they can be used for, and the best practices for maintenance. Whether you’re a business owner looking to improve your energy efficiency or simply someone interested in learning more about this innovative technology, this guide will provide you with all the information you need to make informed decisions about induction thermal oil boilers.

Whether you’re a business owner looking to improve your energy efficiency or simply someone interested in learning more about this innovative technology, this guide will provide you with all the information you need to make informed decisions about induction thermal oil boilers.

Introduction to electromagnetic induction fluid liquid boiler

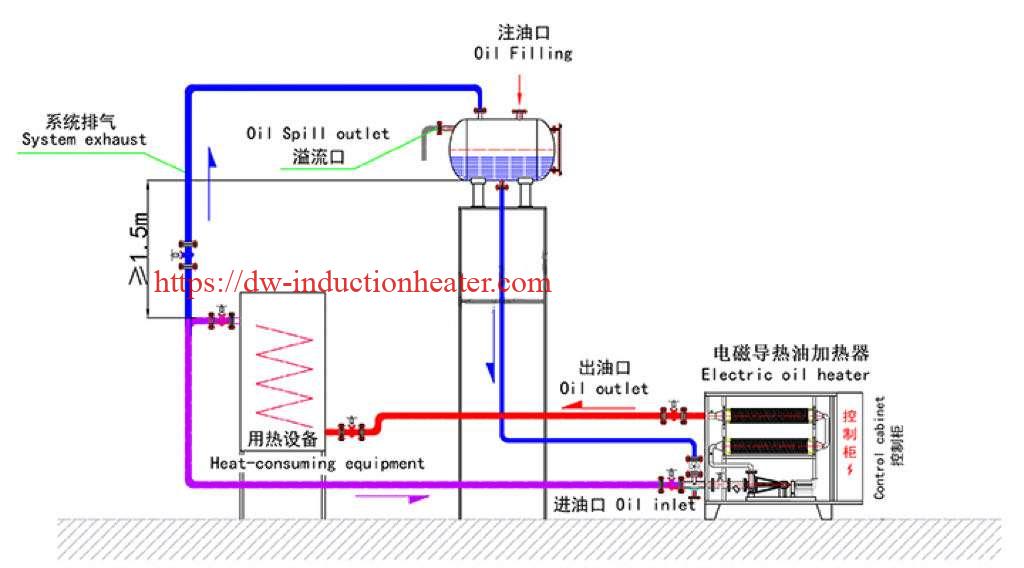

electromagnetic induction fluid liquid boiler is a type of heating system that uses a liquid phase heat transfer medium to transfer heat energy.  They are commonly used in industrial applications where high temperatures are required, such as in the chemical, pharmaceutical, and food industries. Induction thermal oil boilers use electromagnetic induction to heat the heat transfer medium, which is usually thermal oil. The heat is then transferred to the process equipment, where it is used to heat up the process. One of the main benefits of using an induction thermal oil boiler is the high efficiency of heat transfer. This is due to the fact that the heat transfer medium is in a liquid phase, which allows for very efficient heat transfer. Additionally, induction thermal oil boilers are very safe and reliable, as they do not use any open flames or combustion processes. They are also very clean, as they do not produce any emissions or waste products. Overall, induction thermal oil boilers are an excellent choice for industrial heating applications, providing a safe, efficient, and reliable heating solution. In the following sections of this guide, we will explore the benefits, applications, and maintenance of induction thermal oil boilers in more detail.

They are commonly used in industrial applications where high temperatures are required, such as in the chemical, pharmaceutical, and food industries. Induction thermal oil boilers use electromagnetic induction to heat the heat transfer medium, which is usually thermal oil. The heat is then transferred to the process equipment, where it is used to heat up the process. One of the main benefits of using an induction thermal oil boiler is the high efficiency of heat transfer. This is due to the fact that the heat transfer medium is in a liquid phase, which allows for very efficient heat transfer. Additionally, induction thermal oil boilers are very safe and reliable, as they do not use any open flames or combustion processes. They are also very clean, as they do not produce any emissions or waste products. Overall, induction thermal oil boilers are an excellent choice for industrial heating applications, providing a safe, efficient, and reliable heating solution. In the following sections of this guide, we will explore the benefits, applications, and maintenance of induction thermal oil boilers in more detail.

Benefits of electromagnetic induction fluid liquid boiler

electromagnetic induction fluid liquid boilers have become increasingly popular in recent years due to their many benefits. There are several benefits of using an induction heating thermal oil boiler for industrial heating applications. These include:

1. Energy efficiency: electromagnetic induction fluid liquid boilers can achieve a high level of energy efficiency due to the use of electromagnetic induction to heat the oil in the system. This means that less energy is wasted in the heating process, resulting in lower energy bills and reduced environmental impact.

2. Precise control: Induction technology allows for precise control of the heating process, so that the temperature of the oil can be maintained at a consistent level. This is important for applications where temperature control is critical, such as in the production of chemicals or pharmaceuticals.

3. Safety: Induction thermal oil boilers do not use an open flame or hot surface to heat the oil, which reduces the risk of fire or explosion. This makes them a safer option than traditional boilers in many applications.

4. Versatility: Induction thermal oil boilers can be used with a wide range of heat transfer fluids, including synthetic and mineral oils. This makes them suitable for use in a variety of industrial processes and applications.

5. Low maintenance: Induction thermal oil boilers require minimal maintenance, as there are no moving parts that need regular servicing. This reduces downtime and maintenance costs over the lifetime of the system.

6. Long lifespan: Induction thermal oil boilers have a long lifespan, as they are built from durable materials and do not suffer from the same wear and tear as traditional boilers. This means that they offer a good return on investment over time.

Applications of electromagnetic induction fluid liquid boilers

electromagnetic induction fluid liquid boilers are used in a variety of industrial heating applications, including:

1. Chemical Processing: Induction heating thermal oil boilers are used in chemical processing applications to heat reactors, distillation columns, and other equipment.

2. Food Processing: Induction heating thermal oil boilers are used in food processing applications to heat kettles, ovens, and other equipment.

3. Plastics Processing: Induction heating thermal oil boilers are used in plastics processing applications to heat extruders, injection molding machines, and other equipment.

4. Textile Processing: Induction heating thermal oil boilers are used in textile processing applications to heat dyeing machines, finishing machines, and other equipment.

Maintenance of induction thermal oil boilers

Induction thermal oil boilers are an essential part of many industrial processes that require high temperatures to be sustained over a prolonged period of time. As with any machinery, regular maintenance is essential to ensure that it continues to function optimally. Regular maintenance of induction thermal oil boilers includes checking and adjusting the thermostat, inspecting the fuel and water supply lines for leaks, ensuring that the oil is clean and free of contaminants, and checking the pressure of the system. It is also essential to regularly clean the heating coils and the burners to ensure that they are free from any build-up that can cause blockages and lead to reduced efficiency.  In addition, it is important to check the electrical connections and wiring to ensure that the system is working safely and effectively. Regular maintenance not only ensures that the system is working efficiently but also helps to prolong its lifespan, reducing the frequency of costly repairs and replacements. Ultimately, by investing in regular maintenance, you can avoid downtime, increase productivity, and ensure that your induction thermal oil boiler continues to deliver reliable and consistent performance.

In addition, it is important to check the electrical connections and wiring to ensure that the system is working safely and effectively. Regular maintenance not only ensures that the system is working efficiently but also helps to prolong its lifespan, reducing the frequency of costly repairs and replacements. Ultimately, by investing in regular maintenance, you can avoid downtime, increase productivity, and ensure that your induction thermal oil boiler continues to deliver reliable and consistent performance.

Conclusion

electromagnetic induction fluid liquid boilers are a game-changer for the heating industry. They offer significant advantages over traditional heating systems, including high efficiency, rapid heating, precise temperature control, and low maintenance. These benefits make them an ideal solution for a wide range of industrial heating applications. As the heating industry continues to evolve, it is likely that induction heating thermal oil boilers will become even more prevalent, helping to improve efficiency and reduce environmental impact.

Related products

-

Induction Heating for Disassembly and Assembly large bearings, shaft couplings, propeller hubs and Turbine Bearings in Shipbuilding Industry and Heavy Machinery Maintenance

-

Induction Post Weld Heating Treatment Machine

-

Electromagnetic Induction Heating Steam Generators

-

stress relief heat treatment with induction