-

1/1

brazing carbide tips

Categories: Applications, Induction Brazing, induction brazing machine

Tags: brazing carbide, brazing carbide induction heater, brazing carbide tips induction, carbide tips, carbide tips brazing, carbide tips induction brazing, induction brazing carbide, induction brazing carbide tips, induction soldering carbide tips, soldering carbide tips

Equipment

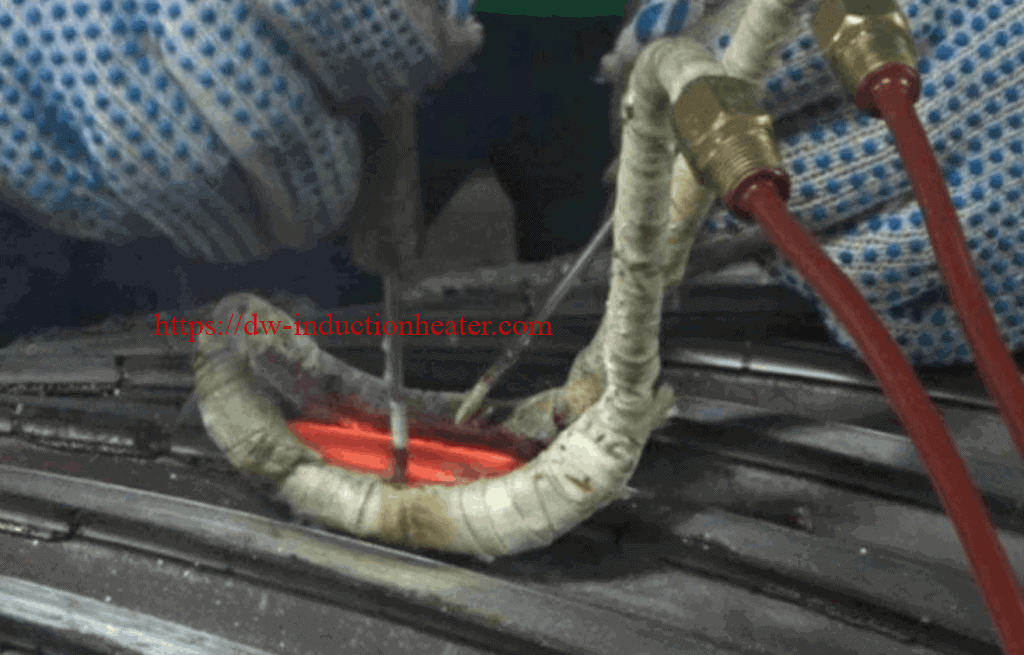

DW-UHF-20kw induction brazing machine

Power: 11,5kW (max)

Time: 10 sec (to brazing temperature)

Process Steps

1. Induction Heating to brazing temperature to remove stale tool

2. Removing old solder during heating

3. Braze new tool

Results and Conclusions:

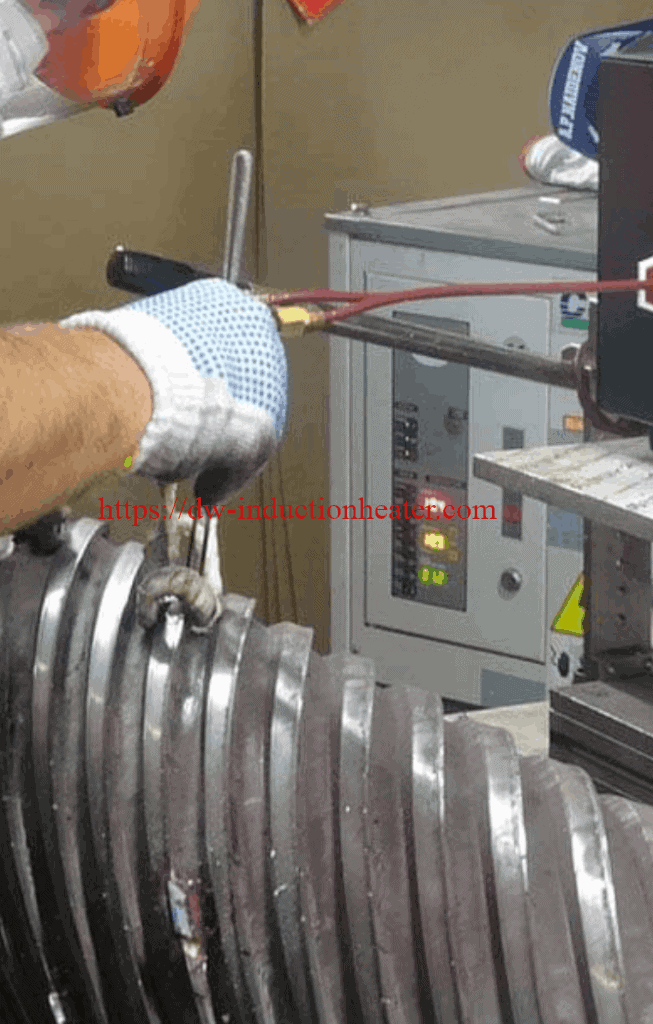

1. The delivered power to the load was more than enough and the test was performed successful

2. Coil bar connection between customer induction coil and our heat station was only for test purposes

3. Using of foot-switch for this application is useful for this application

Conclusions:

The induction heating machine performance exceeds customer expectations. The customer was very happy to reduce the time needed for worn carbide tips replacement.