-

1/6

-

2/6

-

3/6

-

4/6

-

5/6

650 °C – 1300 °C high temperature multi zone tube furnace

What is a High-Temperature Multi-Zone Tube Furnace?

A high-temperature multi-zone tube furnace is a type of furnace that offers unparalleled temperature precision across several heating zones within the same apparatus. Constructed with high-purity quartz or alumina tubes, these furnaces facilitate various heat treatments with each zone capable of operating under different temperatures. This capability ensures the creation of specific and controlled thermal environments, essential for a wide range of scientific and engineering processes .

High-temperature multi-zone tube furnaces are advanced laboratory equipment used for various applications requiring controlled temperature environments. These furnaces typically use high-purity quartz or alumina tubes and feature multiple heating zones (ranging from 2 to 5, or even up to 8 zones) that can be controlled separately. This design allows for precise temperature profiles and excellent uniformity across different sections of the furnace. They are capable of reaching maximum temperatures up to 1300℃, with some specialized models designed for higher temperatures. The multi-zone control is particularly useful for thermo-treatments under vacuum conditions and gas protection, providing versatility for research and industrial applications in materials science, chemistry, and engineering. Customization options, such as varying the heating zone length and the number of zones, are also available to meet specific requirements .

Applications and Uses

High-temperature multi-zone tube furnaces find extensive applications in the fields of materials science, chemistry, physics, and engineering. Their ability to create controlled atmospheres and precise temperature gradients makes them ideal for a variety of processes. Notable applications include thermo-treatments under vacuum or gas protection, synthesis of advanced materials, and the study of phase transitions. The versatility of these furnaces allows researchers and engineers to push the boundaries of what is possible in material synthesis and modification, contributing significantly to advancements in technology and science .

The HLQ company’ Large Multi-temperature Zone Tube Furnace offers the benefits of simultaneous heating and mixing of the sample, in addition to the use of an inert atmosphere.

The furnaces are suitable for continuous material processing. Residence time in the heated zone depends on the degree of inclination and the rotating speed (which can be controlled by the customer) and the length of the working tube, in addition to the flow properties of the material.

The design of the split furnace, drive system and feeder/ collection assemblies allows the work tube to be easily removed and replaced.

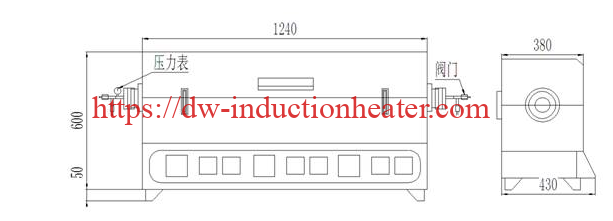

The single zone and Multi-heating zone split tube furnaces have a maximum operating temperature of 1300 °C. All models are available with maximum heated lengths of 7500mm.

Standard features

- 1300 °C maximum operating temperature; normal operating temperature range 650 °C – 1250 °C

- Heated lengths options(3000、4000、5000、6000、9000、12000 and so on)

- Heating tube diameter(80、90、100、110、150、220、300、350、500、600)

- Single zone models fitted with PID controller with the single ramp to setpoint

- Single or 3-zone models or multi-heating zone.

- Adjustable inclination and rotation speeds offer the flexibility of residence time

- Work tube rotation speed 1.5 to 10.0 revolutions per minute

- The temperature controllers and associated equipment are housed within the integral control box

- Wire elements in high-quality vacuum formed insulation ensures fast heat up, excellent temperature uniformity and short cooldown times

- Vacuum degree can be -0.1Mpa

In summary, high-temperature multi-zone tube furnaces represent a critical advancement in the ability to manipulate and understand the properties of materials under specific thermal conditions. Their design, functionality, and wide range of applications not only enhance research capabilities but also pave the way for innovations in various scientific and industrial fields.

In summary, high-temperature multi-zone tube furnaces represent a critical advancement in the ability to manipulate and understand the properties of materials under specific thermal conditions. Their design, functionality, and wide range of applications not only enhance research capabilities but also pave the way for innovations in various scientific and industrial fields.