-

1/5

-

2/5

-

3/5

-

4/5

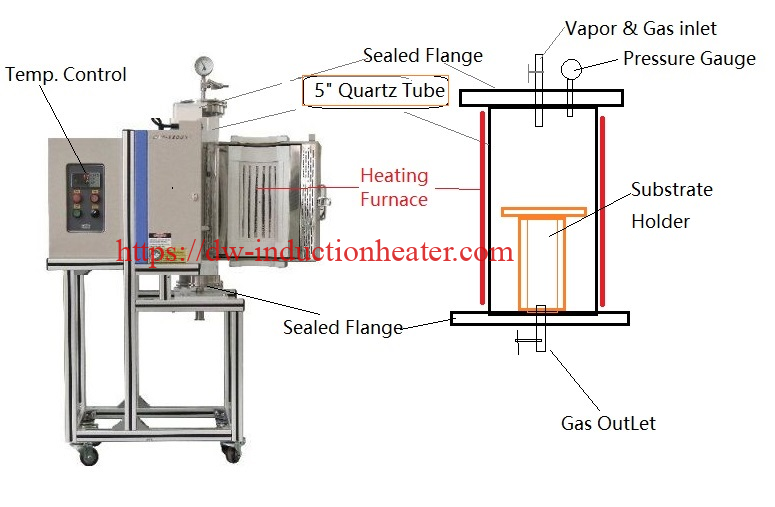

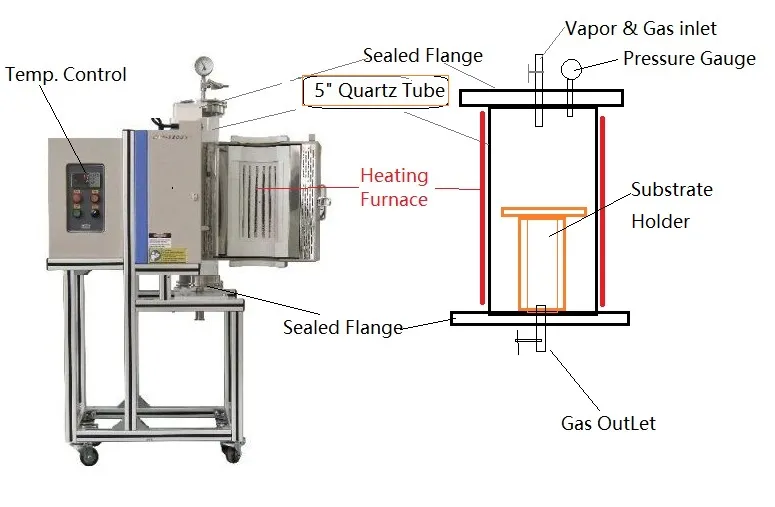

1200°C – 1800°C vertical Split tube furnace-high temperature tubular furnace

What’s the vertical split tube furnace ?

A vertical split tube furnace is a type of furnace that has a vertically oriented heating chamber, which is split into two halves. This design allows for easy loading and unloading of samples or materials into the furnace.

The split tube furnace typically consists of a cylindrical heating chamber, which is made of a refractory material such as alumina or quartz. The heating element is wound around the outside of the chamber to provide uniform heating.

The split tube design allows for convenient access to the heating chamber. One half of the chamber can be opened, either manually or with a motorized mechanism, to allow for easy insertion and removal of samples or materials. This is especially useful for processes that require frequent loading and unloading or for experiments that involve multiple samples.

The split tube furnace is often used in research laboratories and industrial applications for various heat treatment processes such as annealing, sintering, and brazing. It is also popular in materials science and metallurgy for studying the properties of different materials at high temperatures.

Application Examples

annealing, carbonisation, crystal growth, debinding, degassing, drying, glowing, hardening, metal injection moulding (MIM), pyrolyses, rapid prototyping, sintering, sublimation, synthesis, tempering

Standard features

- 1800 °C maximum operating temperature

- Double layer furnace shell air cooling ensure the surface temperature less than 45℃

- Temperature accuracy :±1℃; Temperature uniformity:±1℃(Base on Heating zone size)

- intelligent current and voltage meter temperature controller, simple to use, Programmable

- Optimised for vertical usage

- Low thermal mass ceramic fibre insulation

- Vertically hanging, high quality MoSi2 heating elements

- Double loop protection(over current, over temperature and over voltage etc)

- Metal, Quartz, Corundum materials can be selected as the tube material

- Vacuum degree can be -0.1Mpa

Spes:

| Temperature | 1200℃ | 1400℃ | 1600℃ | 1700℃ | 1800℃ |

| Voltage AC | 220V/380V | 220V/380V | 220V/380V | 220V/380V | 220V/380V |

| Long-term operating temperature | 1150℃ | 1350℃ | 1550℃ | 1650℃ | 1750℃ |

| Temperature control accuracy | ±1℃ | ||||

| Furnace tube material | Stainless steel tube/quartz glass tube/corundum tube | corundum tube | |||

| Temperature field uniformity in the furnace | ±1℃ (depending on the size of the heating chamber) Multi-point temperature control can be used when higher requirements are required | ||||

| Temperature measuring element and temperature measuring range | Nickel chromium nickel silicon K temperature measurement range 0-1350℃ | S type | Type B | ||

| Number of programmed curve segments | One group has 50 segments, the second group has 22 segments, and the third group has 8 segments. | ||||

| Heating rate | Adjustable from 1℃/h to 40℃/min | ||||

| Heating element | Silicon carbide rod | Silicon carbide rod | Silicon molybdenum rod | ||

| Heating element location | The installation position is around the furnace tube and horizontal to the furnace tube. | ||||

| Refractory materials | High purity alumina fiber board | ||||

| Warranty scope and period | The electric furnace has a one-year free warranty. The heating element and furnace tube are not under warranty (the heating element will be replaced free of charge if it is naturally damaged within three months). | ||||

| Random spare parts | Two heating elements, two sets of rods , one instruction manual, one certificate of conformity, one furnace door insulation brick, one crucible pliers , one pair of high-temperature gloves, one special crucible for tube furnace, and two sealing rings | ||||

In conclusion, the vertical split tube furnace is a valuable tool for researchers, engineers, and manufacturers who require precise and reliable high-temperature heating capabilities. Its robust construction, versatile design, precise temperature control, and safety features make it an essential piece of equipment for a wide range of applications in industries such as materials science, metallurgy, semiconductor processing, and more. As technology continues to advance, we can expect further improvements in vertical split tube furnace design and functionality, leading to even greater efficiency and performance in high-temperature processing and experimentation.

In conclusion, the vertical split tube furnace is a valuable tool for researchers, engineers, and manufacturers who require precise and reliable high-temperature heating capabilities. Its robust construction, versatile design, precise temperature control, and safety features make it an essential piece of equipment for a wide range of applications in industries such as materials science, metallurgy, semiconductor processing, and more. As technology continues to advance, we can expect further improvements in vertical split tube furnace design and functionality, leading to even greater efficiency and performance in high-temperature processing and experimentation.

[pdf-embedder url=”https://dw-inductionheater.com/wp-content/uploads/2024/03/Industrial-Electric-Tube-Furnace.pdf” title=”Industrial Electric Tube Furnace”]