high frequency induction preheating copper rod and connector for an epoxy curing application

induction preheating copper rod and connector for an epoxy curing application

Objective: To preheat a portion of the copper rod and a rectangular connector to temperature prior to epoxy curing during a manufacturing process for electrical turnbuckles

Material : Customer supplied plated copper rod (12” x 2” x 1”/305mm x 51mm x 102 mm) and connector

Temperature :302 ºF (150 ºC)

Frequency :25 kHz

Induction Heating Equipment:

-DW-HF-60kW 15-45 kHz induction heating system equipped with a remote workhead containing four 21 μF capacitors

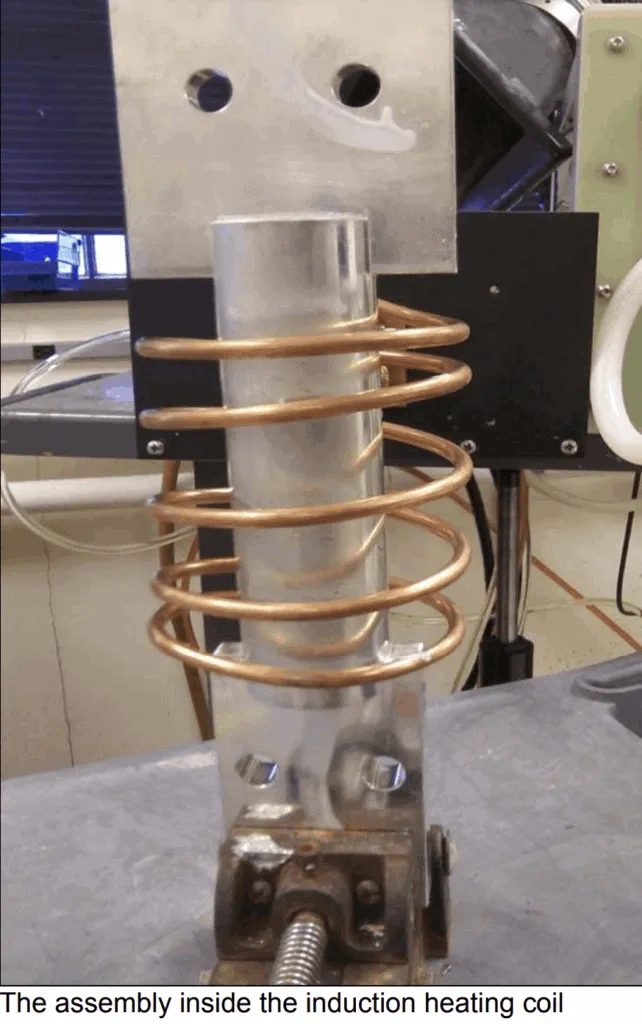

– A single position seven-turn helical induction heating coil designed and developed specifically for this application

Induction Heating Process

The copper rod and connector were placed inside the induction heating coil and the power was turned on. The part heated to temperature within 55 seconds. After being heated to temperature, the part was moved and an epoxy curing/molding process took place. The client was using a large oven to preheat these rods, which

was cost inefficient. Induction offers a faster and more costefficient heating method.

Results/Benefits – Speed: Induction heated the part to temperature quickly

– Efficiency: Induction is a far more efficient method of heating these parts to temperature when compared to their

large oven

– Precision: Induction made it possible to heat only the parts of the rod that required heating