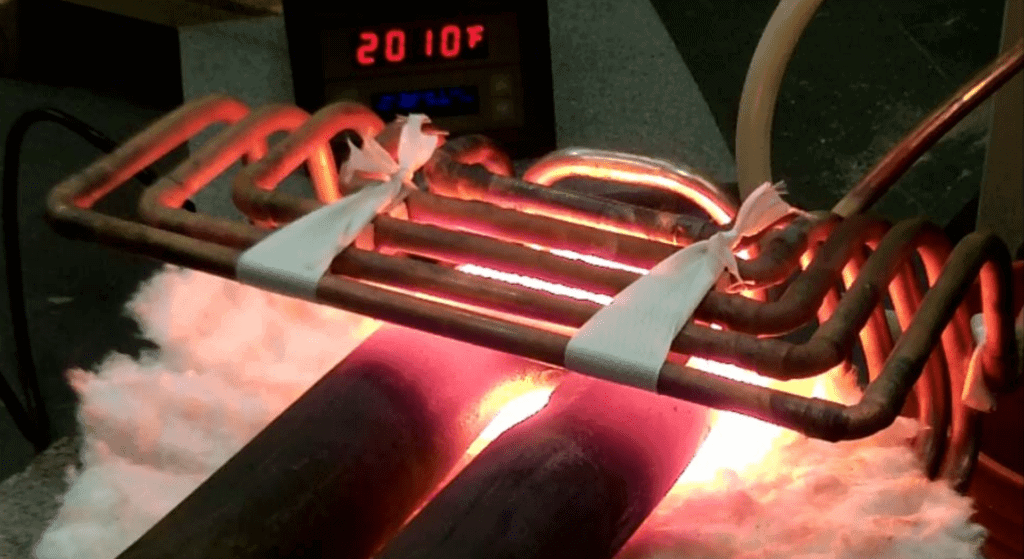

Induction Hot Forming Steel Pipe

Objective : To heat a magnetic steel pipe to the targeted temperature to enable pipe induction bending; the objective is to create u-bends in pipes for boiler systems

Material: Steel pipes (2.5”/64 mm OD bent steel pipe)

Temperature: 2010 °F (1099 °C)

Frequency: 8.8 kHz

Equipment : DW-MF-250 kW, 5-15 kHz induction heating power supply with a remote workhead containing eight 6.63 μF capacitors for a total of 53 μF.

– A single position six-turn channel induction heating coil designed and developed for this application

Process: The steel pipe was placed inside the induction coil, and it heated to temperature within 120 seconds with an DW-MF- 250kW/10 kHz induction heating system.

Speed: A large steel pipe heated to the targeted temperature quickly

– Repeatability: Induction is highly repeatable and easy-tointegrate into manufacturing processes

– Precise heating: Induction is able to target the portion of the tube that requires bending while not heating the remainder of the tube

– Energy efficiency: Induction offers fast, flameless, instant on/instant off heating