Induction bending pipe

What is Induction Bending?

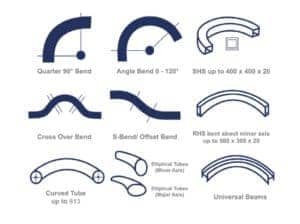

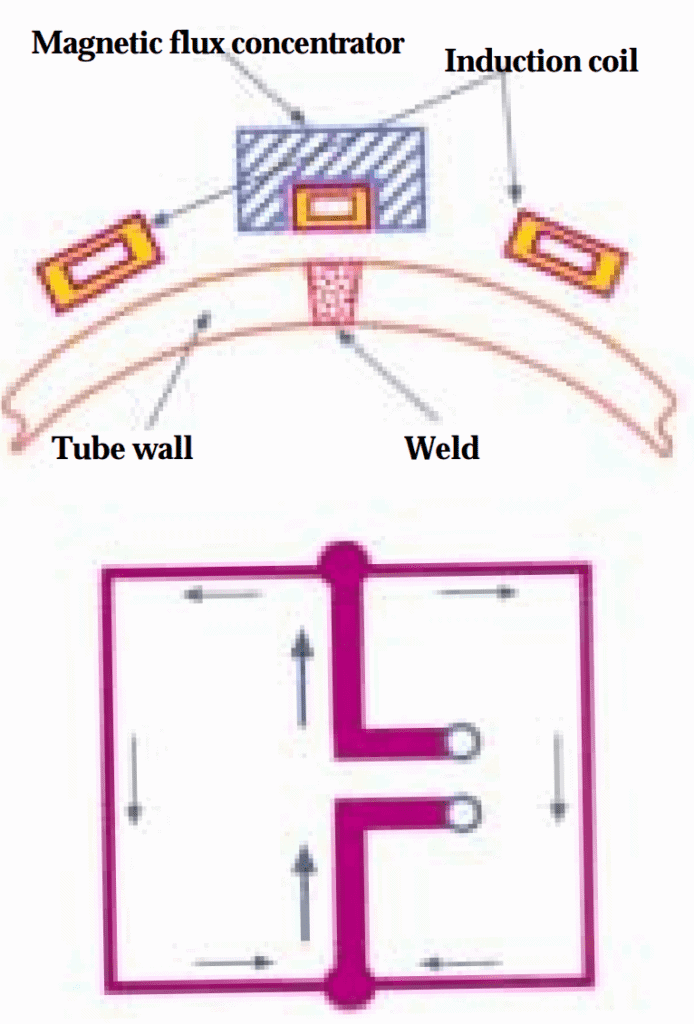

Induction Bending is a precisely controlled and efficient piping bending technique. Local heating using high frequency induced electrical power is applied during the induction bending process. Pipes, tubes, and even structural shapes (channels, W & H sections) can be bent efficiently in an induction bending machine. Induction bending is also known as hot bending, incremental bending, or high-frequency bending. For bigger pipe diameters, when cold bending methods are limited, Induction bending is the most preferable option. Around the pipe to be bent, an induction coil is placed that heats the pipe circumference in the range of 850 – 1100 degrees Celsius.

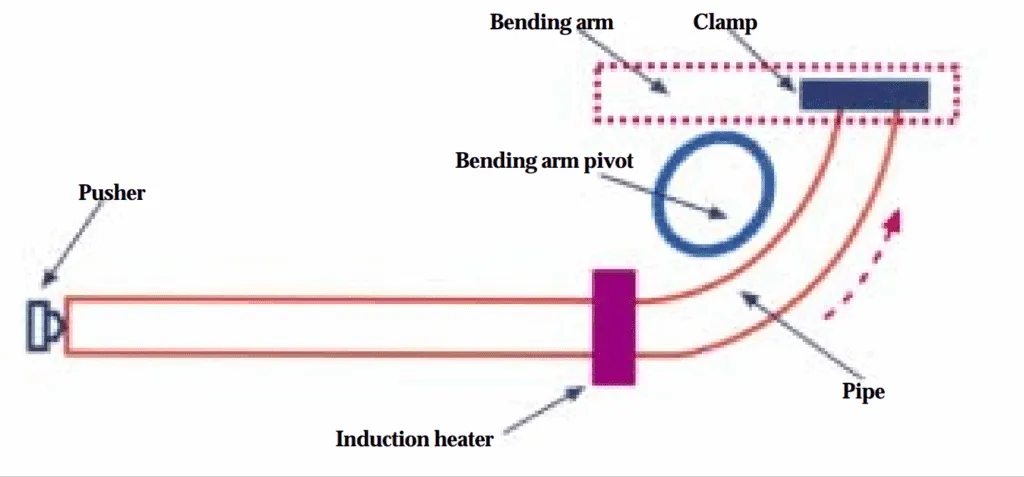

An induction bending pipe/tube machine is sketched in the photo. After positioning the pipe and securely clamping its ends, power is applied to a solenoid-type inductor that provides circumferential heating of the pipe in the area where it will be bent. When a temperature distribution that provides sufficient ductility to the metal at the region of bending has been attained, the pipe is then pushed through the coil at a certain speed. The pipe’s leading end, which is clamped to the bending arm, is subjected to a bending moment. The bending arm can pivot up to 180°.

In induction bending of carbon steel pipe, the length of the heated band usually is 25 to 50 mm (1 to 2 in.), with a required bending temperature in the 800 to 1080°C (1470 to 1975°F) range. As pipe passes through the inductor, it bends within the hot, ductile region by an amount dictated by the radius of the bending arm pivot, while each end of the heated region is supported by a cold, nonductile section of pipe. Depending upon the application,

bending speed can range from 13 to 150 mm/min (0.5 to 6 in./min). In some applications where larger radii are required, a set of rolls is used to provide the required bending force instead of a bending arm pivot.After the bending operation, the pipe is cooled to ambient temperature using a water spray, forced air, or natural cooling in air. A stress relief or temper can then be conducted to obtain required post-bend properties.

Wall thinning: Induction heating provides rapid circumferential heating of selected areas of the pipe, consuming a minimum amount of energy compared with other hot bending processes in which the entire pipe is heated. There also are other important benefits provided by induction tube bending. These include highly predictable shape distortion (ovality) and wall thinning. Minimization and predictability of wall thinning are particularly critical when producing tubes and pipes for applications that must meet high-pressure requirements,such as nuclear power and oil/gas pipelines. For example, oil and gas pipeline ratings are based on wall thickness. During bending, the outer side of the bend is in tension and has a reduced cross section, while the inner side is in compression. When conventional heating is used in bending, the cross section of the outer side of the bend area often is reduced by 20% or more resulting in a corresponding reduction of the total pipeline pressure rating.The pipe bend becomes the pipeline’s pressure-limiting factor.

With induction heating, the reduction in cross section is reduced to typically 11% due to very even heating, an optimized bending program via a computerized bending machine, and a narrow plasticized (ductile) zone. Consequently, induction heating not only reduces production costs and increases bend quality, but also reduces total pipeline cost.

Other important advantages of induction bending: it is not labor intensive, it has little effect on surface finish, and it has the ability to make small radii, which enables bending of thinwall tubes and the production of multiradius curves/multiple bends in one pipe.

Benefits of Induction Bending:

Benefits of Induction Bending:

- Large radii for smooth flow of fluid.

- Cost efficiency, straight material is less costly than standard components (e.g. elbows) and bends can be produced faster than standard components can be welded.

- Elbows can be replaced by larger radius bends where applicable and subsequently friction, wear and pump energy can be reduced.

- Induction bending reduces the number of welds in a system. It removes welds at the critical points (the tangents) and improves the ability to absorb pressure and stress.

- Induction bends are stronger than elbows with uniform wall thickness.

- Less non-destructive testing of welds, such as X-ray examination will save cost.

- Stock of elbows and standard bends can be greatly reduced.

- Faster access to base materials. Straight pipes are more readily available than elbows or standard components and bends can almost always be produced cheaper and faster.

- A limited amount of tools is needed (no use of thorns or mandrels as required in cold bending).

- Induction bending is a clean process. No lubrication is needed for the process and water needed for the cooling is recycled.

ADVANTAGES OF USING INDUCTION BENDING

- Infinitely variable bend radius, offering optimum design flexibility.

- Superior quality in terms of ovality, wall thinning and surface finish.

- Avoids the need for components with an elbow, allowing cheaper, more readily available straight materials to be utilised.

- A stronger end product than elbows with a uniform wall thickness.

- Large radius bend capability reduces friction and wear.

- Surface quality of bent material is not relevant in terms of suitability for use.

- Quicker production times than the welding of separate components.

- No cutting, rounding-up, match boring, fitting or heat treating/welding of forged fittings.

- Pipe and other sections can be curved to smaller radii than with cold bending techniques.

- Material surface unaffected/unblemished by the process.

- Multiple bends possible on a single length of pipe.

- Reduced welding requirement with compound bends, improving finished pipework integrity.

- Welds avoided at critical points.

- Less need for non-destructive testing, driving costs further down.

- Faster and more energy efficient than traditional fire/hot slab bending methods.

- Process eliminates the need for sand filling, mandrels or formers.

- A clean, lubricant-free process.

- Bend specification changes are possible right up to the last minute before production.

- Reduced need for formal on-site inspection of welded joint integrity.

- Faster repair and maintenance lead times, due to relative ease of producing replacement induction-bent pipes or tubes.