induction coating removal for removing paint

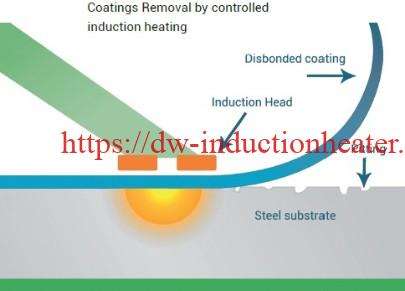

Induction coating removal principle

The induction disbonder works by the principle of induction. Heat is generated in the steel substrate and the bonding is broken. The coating is then removed entirely without disintegrating and completely free from contaminating agents, i.e. blast media.This obviously makes disposal and recycling of waste easier and cheaper. Even inside the pittings and cracks in the surface the coating is disbonded.

The HLQ Induction heating works by fast transfer of energy to the steel substrate, as a result securing a controlled heating of the surface and fast removal of most types of coatings.

What is induction coating removal?

The HLQ Induction coating removal system is a state-of-the-art induction heating tool that rapidly strips paint and tough, high-build coatings. It is a faster, cleaner and safer way to strip coatings.

What are the benefits?

What are the benefits?

Induction heating can outperform traditional paint-stripping methods. Abrasive blasting or disk grinding are generally more labour intensive and come with other issues such as the cost of enclosure or containment and collection of blast media, plus the filtration or separation of the coating materials for disposal. In many urban projects these are prime considerations and extremely costly to overcome. Whereas, when coatings are removed by induction, the only waste is the coating itself which in most cases can be swept or even vacuumed like any other workshop waste.

Safer working environment: The controlled, localized heat results in significantly reduced fumes and toxic dust.

Easy clean-up: The coating material mainly peels off in flakes rather than being pulverized.

Noiseless operation: Operators can work in public areas without creating a disturbance.

Mobile: The equipment is rugged and reliable but still light-weight and easy to move around worksites.

Reduced energy consumption: Fast, accurate and repeatable heat delivery makes the coating removal process extremely energy efficient.

Method flexibility: Spot heating, scanning, freehand and semi-automatic.

No limitations: The system can be used at flat surfaces, round contours, inside/outside corners, both sides of substrate, round rivets, etc.

Where is it used?

Induction coating removal is used in many industries, such as ships/marine, buildings, storage tanks, pipelines, bridges and offshore.

induction heating involves using alternating current and an induction coil to generate a powerful electro-magnetic field. When used properly, this field generates heat below a coating on a steel substrate, resulting in the coating de-bonding quickly and easily from the metal surface.

At Alliance, we use this process to remove coatings from steel such as:

- Multiple coatings including epoxies, urethanes and others

- Lead paint

- Fire-retardant coatings (PFPs)

- Glued and vulcanized rubber as well as chlorinated rubber

Induction Coating Removal On Storage Tanks –

The Induction Heating System for coatings removal is highly suitable for fast and efficient stripping of large surfaces or for inspection of weld seams in storage tanks. Experience from work on tank bottoms have shown that thick glass-fiber (5-6 mm) can be removed with stripping rates up to 10-12 m2/hr. while thinner traditional painting systems can be removed in rates up to 35 m2/hr.

Not only does the Induction system yield great economic benefits like higher stripping rates and minimal waste disposal, but it is also enables environmentally – and operator friendly operation.

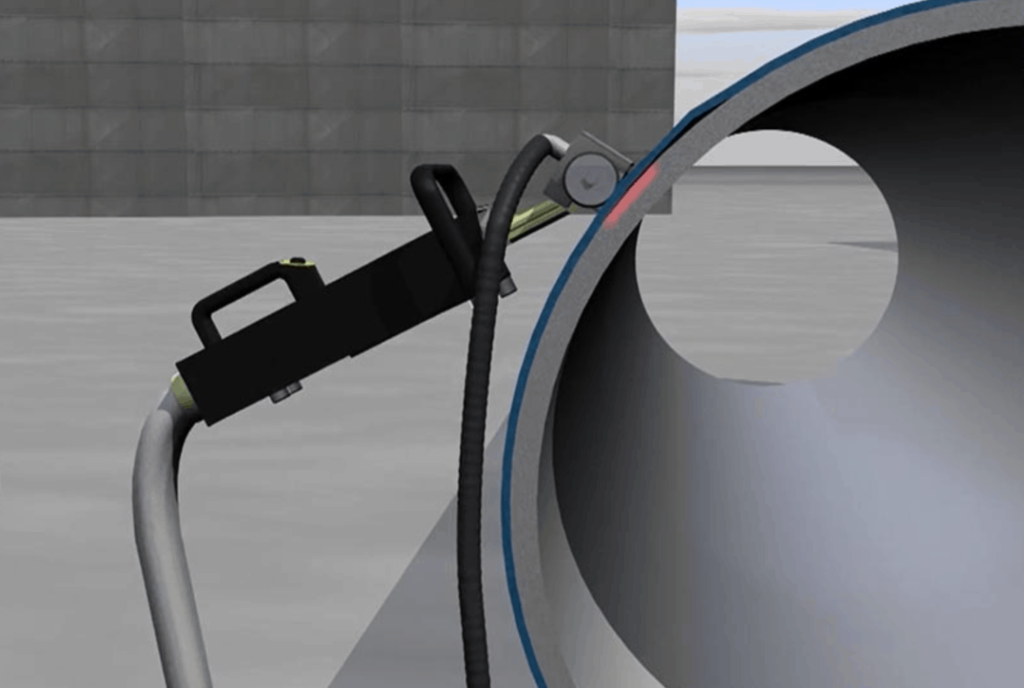

Induction Coating Removal On Pipelines –

The patented HLQ Induction Heating System for coatings removal has proven to be very effective on pipes and live pipeline projects around the world. It efficiently and safely removes coatings such as Coal Tar, Ebonite, 3LPE/3LPP, rubber and other tough linings with thickness up to 30 mm.

Coatings removal with HLQ Technologies is cost effective and does not produce additional grit or water waste, yielding great potential for savings in logistic handling, especially in remote areas.The coatings is removed easily in strips or pieces that is easy to put in waste bags for disposal without risk of contamination to air, ground or water.

Working distance from the main unit is up to 100m that allows a flexible and efficient operation. HLQ has developed a patented solution that eliminates the risk of overheating the surface when using the induction system on steel. This has been a prerequisite in the process of successfully receiving approval for use on live oil- and gas pipelines.