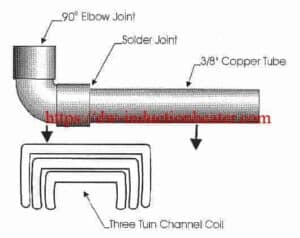

Induction Soldering Copper Tube With High Frequency Heating Units

Objective: To heat a section of 3/8″ copper tubing along with a 900 elbow for soldering. The copper tubing is to be used in Ice Machine Evaporator Assemblies, and soldering takes place after the tubes have been placed within the assembly. Heating must take place in a channel type coil to provide easy access, once the tubing has been installed. Solder can be manually fed after temperature

has been reached.

Material: 3/8″ Thin Walled Copper Tubing and 900 Elbow

Temperature: 6000F

Application: Through the use of the DW-UHF-20kW output solid state induction power supply and a unique three (3) turn channel coil, the following results were achieved:

6000F was reached in 10 seconds.

A quality solder joint was observed with adequate flow and surface texture.

Equipment: DW-UHF-20kW output solid state induction power supply including one (1) remote heat station containing one (1) 1.2 μF capacitor, and a unique three (3) turn channel coil.

Frequency: 200 kHz