Application of Induction Heating In Food

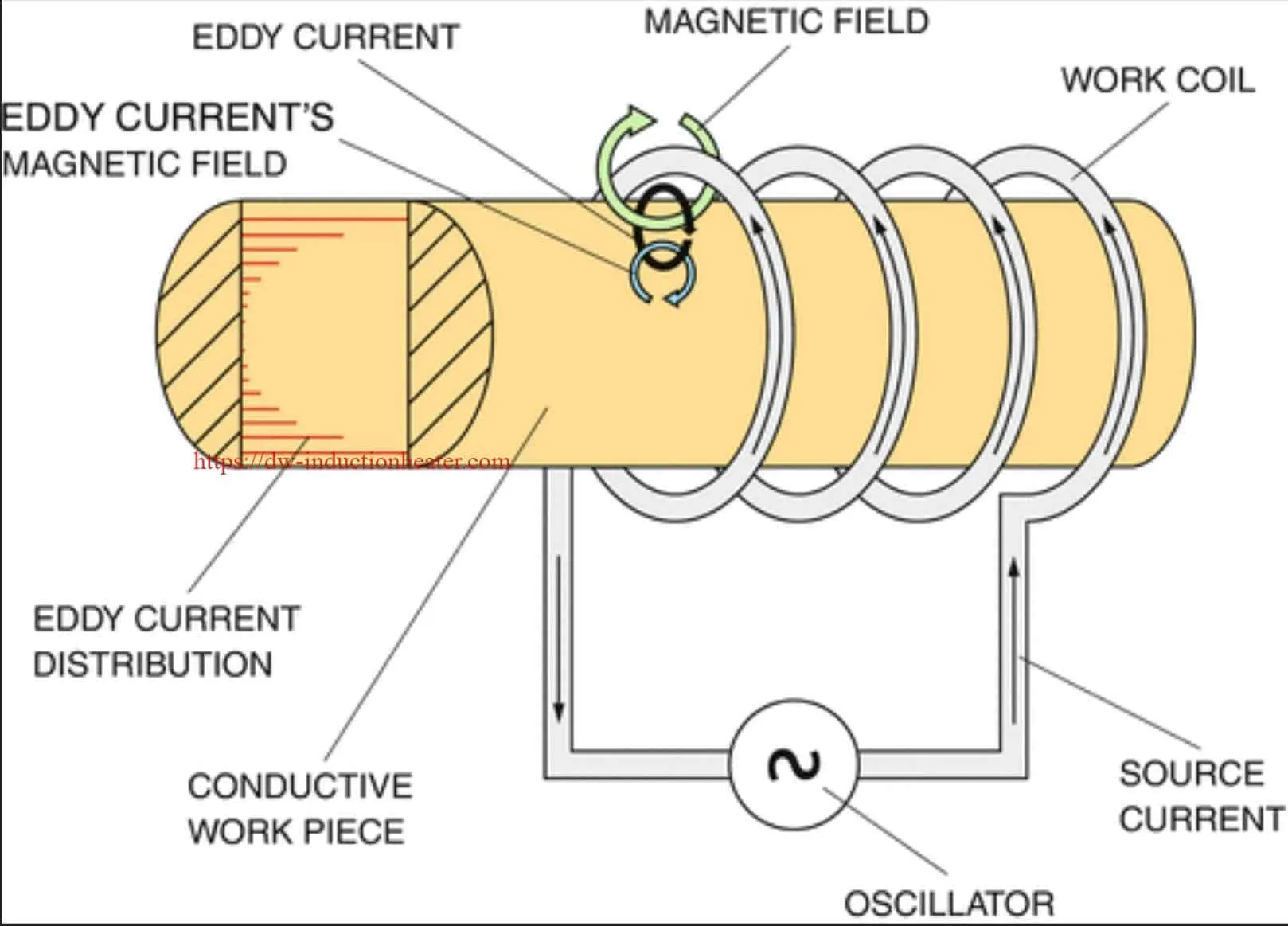

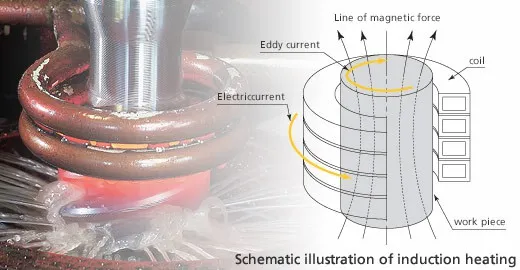

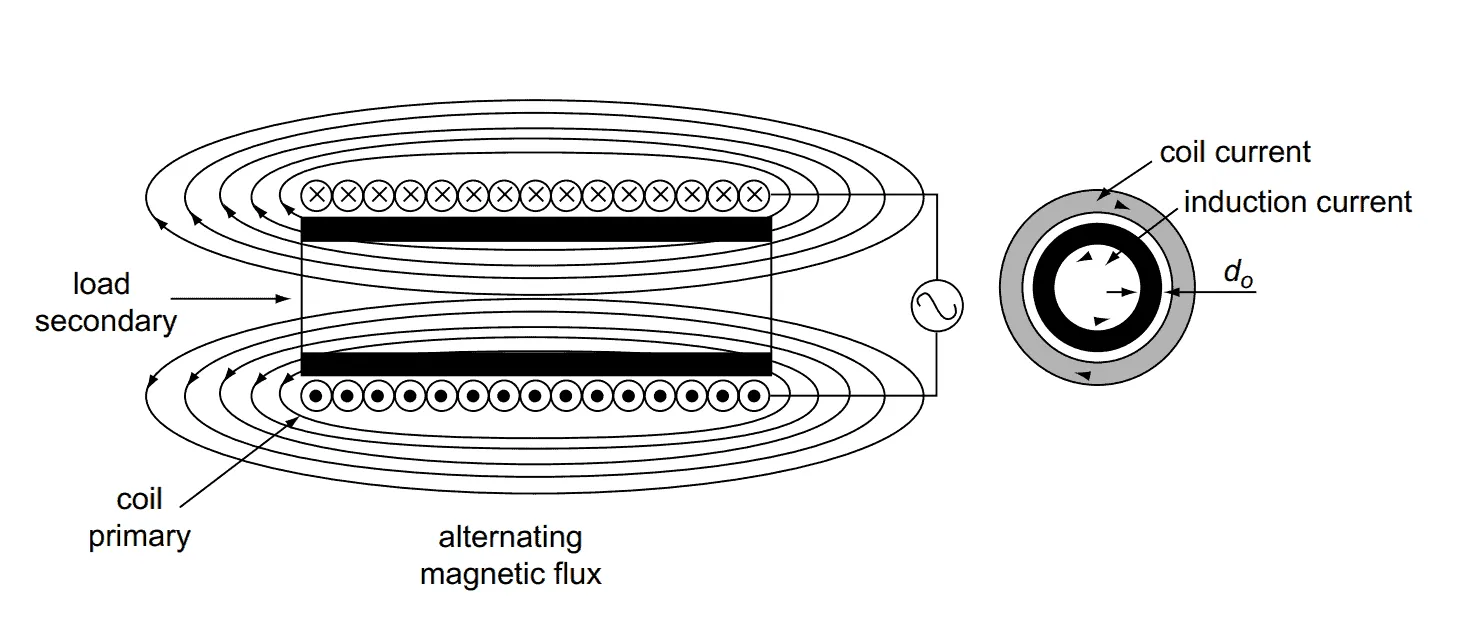

Application of Induction Heating In Food Processing Induction heating is an electromagnetic heating technology that has several advantages such as high safety, scalability, and high energy efficiency. It has been applied for a long time in metal processing, medical applications, and cooking. However, the application of this technology in food processing industry is still in … Read more