Induction Heating Steel Part For Hot Heading With IGBT Induction Heater

Objective Heating steel parts to 1900ºF (1038ºC) for hot heading application

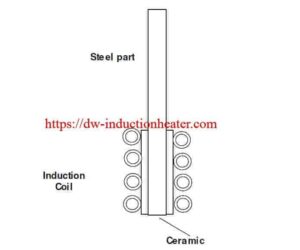

Material Steel parts with 7/16” (11.11mm) OD and ceramic piece

Temperature 1900 ºF (1038ºC)

Frequency 440 kHz

Equipment • DW-UHF-6kW induction heating system, equipped with a remote workhead containing one 0.66μF capacitor.

• An induction heating coil, designed and developed specifically for this application.

Process A four turn helical coil with ceramic insert is used to heat a 0.75” (19mm) section of the part to 1900ºF (1038ºC) for 7.5 seconds. A ceramic piece is so the part does not come in

contact with the coil.

Results/Benefits Induction heating provides:

• Hands-free heating that involves no operator skill for manufacturing

• Direct application of the heat on the work piece with precision and consistency

• Even distribution of heating

• Low pressure and minimal residual part stress