-

1/4

-

2/4

-

3/4

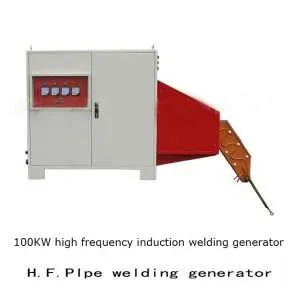

Pipe-Tube Heating Systems With Induction

Pipe-Tube Heating Systems With Induction

Pipe&Tube Induction Heating is the most energy-efficient and controllable method for applying heat during the production of tubular products.The induction heating precessing of pipe&tube includes drilling, threading, welding and other types of mechanical deformation which may require heat treatment to harden the metal or to eliminate residual stresses. In addition, tube&pipe ends are often heated and then upset (formed) to increase or decrease the diameter or wall thickness to allow pipes to be joined end-to-end.

DAWEI Induction pipe&tube heating systems are designed for a variety of these applications including:

- Heat Treat Quench and Temper of Tubing and Pipe

- Upset Processing for Heat Treating

- Pre-heating for Upsetting

- Heating Rod Upsetting

- Swedge End Stress Relieving

- Preheating Tool Joint

- Curing & Pre-heating of Coatings

- Swivel Joint Bending

- Pipe Bending

- De-Bonding of Rubber

- Continues Coiled Tube Processing

- Seamless Mill Billet Pre-heaters

- Seamless Finishing Taper Re-heaters

- Solution Annealing

- Bright Annealing

- Hot Reduction

- Hybrid Gas/Induction lines