-

1/5

-

2/5

-

3/5

-

4/5

High Frequency Seamless Tube Welding Machine

The High Frequency Seamless Tube Welding Machine: A Revolutionary Technology in the Manufacturing Industry

The manufacturing industry is constantly evolving, and new technologies are constantly emerging to make production more efficient and cost-effective. One such revolutionary technology that is making waves in the industry is the high frequency seamless tube welding machine. This cutting-edge technology has transformed the way manufacturers produce seamless tubes, offering numerous benefits in terms of speed, quality, and cost-effectiveness. In this post, we will take a closer look at this innovative technology, exploring how it works, its benefits, and its many applications in the manufacturing industry. Whether you are a manufacturer looking to improve your production processes or simply curious about the latest advancements in manufacturing technology, this post is for you.

In this post, we will take a closer look at this innovative technology, exploring how it works, its benefits, and its many applications in the manufacturing industry. Whether you are a manufacturer looking to improve your production processes or simply curious about the latest advancements in manufacturing technology, this post is for you.

What is a high frequency seamless tube welding machine?

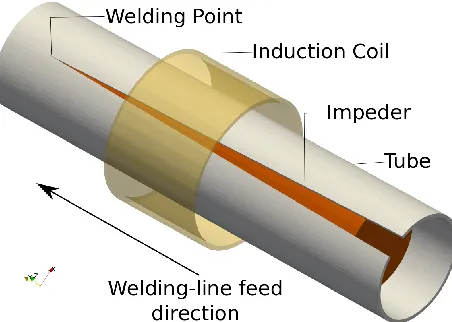

A high frequency seamless tube welding machine is a cutting-edge technology used in the manufacturing industry for the production of seamless tubes. This machine is designed to weld two metal surfaces of a tube seamlessly and quickly using high-frequency electrical currents. The technology behind this machine is based on the concept of induction heating, which is a method of heating a metal by exposing it to an electromagnetic field. This field causes the metal to heat up quickly and melt, allowing it to be joined with another metal surface.  The high frequency seamless tube welding machine uses this principle to produce high-quality and seamless tubes that are strong, durable, and reliable. The machine is equipped with advanced features that help to ensure precise and accurate welding, such as automatic controls, sensors, and monitoring systems. With the high-frequency seamless tube welding machine, manufacturers can produce seamless tubes with high precision and consistency, resulting in reduced production costs and improved efficiency. This revolutionary technology has transformed the manufacturing industry, making it possible to produce high-quality seamless tubes that are widely used in various applications such as automotive, aerospace, and construction.

The high frequency seamless tube welding machine uses this principle to produce high-quality and seamless tubes that are strong, durable, and reliable. The machine is equipped with advanced features that help to ensure precise and accurate welding, such as automatic controls, sensors, and monitoring systems. With the high-frequency seamless tube welding machine, manufacturers can produce seamless tubes with high precision and consistency, resulting in reduced production costs and improved efficiency. This revolutionary technology has transformed the manufacturing industry, making it possible to produce high-quality seamless tubes that are widely used in various applications such as automotive, aerospace, and construction.

How does a high frequency seamless tube welding machine work?

A high frequency seamless tube welding machine is a cutting-edge technology that has revolutionized the manufacturing industry. It is used to create seamless tubes that are used in various applications, including construction, transportation, and energy. So, how does this machine work? The process begins with the raw material, which can be either a coil or a straight bar. The material is then fed into the machine, which starts the process of forming the tube. The machine uses high-frequency current to heat the material, which causes it to fuse together.  Once the material is heated, it is passed through a series of rollers that shape it into a tube. The machine also uses a welding head that applies pressure to ensure a strong and seamless weld. The welding head is designed to move along the length of the tube, ensuring that the entire surface is welded correctly. One of the key advantages of using a high frequency seamless tube welding machine is that it can work at a high speed. The machine is capable of producing up to 100 meters of seamless tube per minute, making it an ideal choice for large-scale manufacturing operations.In addition to its speed and efficiency, the high frequency seamless tube welding machine is also known for its accuracy and precision. The machine is designed to create tubes with tight tolerances, which ensures that the final product is of high quality and meets industry standards. In conclusion, the high frequency seamless tube welding machine is a remarkable technology that has transformed the manufacturing industry. Its ability to create high-quality, seamless tubes quickly and efficiently has made it an essential tool for many industrial applications.

Once the material is heated, it is passed through a series of rollers that shape it into a tube. The machine also uses a welding head that applies pressure to ensure a strong and seamless weld. The welding head is designed to move along the length of the tube, ensuring that the entire surface is welded correctly. One of the key advantages of using a high frequency seamless tube welding machine is that it can work at a high speed. The machine is capable of producing up to 100 meters of seamless tube per minute, making it an ideal choice for large-scale manufacturing operations.In addition to its speed and efficiency, the high frequency seamless tube welding machine is also known for its accuracy and precision. The machine is designed to create tubes with tight tolerances, which ensures that the final product is of high quality and meets industry standards. In conclusion, the high frequency seamless tube welding machine is a remarkable technology that has transformed the manufacturing industry. Its ability to create high-quality, seamless tubes quickly and efficiently has made it an essential tool for many industrial applications.

Benefits of using a high frequency seamless tube welding machine

The high frequency seamless tube welding machine is a revolutionary technology that is changing the manufacturing industry. This machine offers numerous benefits that make it a popular choice for manufacturers worldwide. One of the main advantages of using a high frequency seamless tube welding machine is that it is extremely efficient. This machine can produce large quantities of seamless tubes quickly and accurately, which is essential in meeting the demands of modern manufacturing. Moreover, the high frequency seamless tube welding machine produces seamless tubes with a high degree of precision, which is essential in industries such as aerospace, automotive, and medical where tolerances are critical. Another significant benefit of the high frequency seamless tube welding machine is its versatility. This machine can be used to produce tubes of varying sizes and shapes with a wide range of materials, including stainless steel, titanium, and aluminum.  This versatility is essential in meeting the diverse needs of different industries. Additionally, the high frequency seamless tube welding machine requires minimal maintenance, which makes it a cost-effective solution for manufacturers. The high frequency seamless tube welding machine is also eco-friendly, producing minimal waste and reducing the carbon footprint of manufacturers. This is a significant advantage in today’s world, where sustainability is becoming increasingly important to consumers and stakeholders. In conclusion, the high frequency seamless tube welding machine offers numerous benefits that make it a revolutionary technology in the manufacturing industry. Its efficiency, precision, versatility, and sustainability make it a popular choice for manufacturers worldwide.

This versatility is essential in meeting the diverse needs of different industries. Additionally, the high frequency seamless tube welding machine requires minimal maintenance, which makes it a cost-effective solution for manufacturers. The high frequency seamless tube welding machine is also eco-friendly, producing minimal waste and reducing the carbon footprint of manufacturers. This is a significant advantage in today’s world, where sustainability is becoming increasingly important to consumers and stakeholders. In conclusion, the high frequency seamless tube welding machine offers numerous benefits that make it a revolutionary technology in the manufacturing industry. Its efficiency, precision, versatility, and sustainability make it a popular choice for manufacturers worldwide.

Applications of a high frequency seamless tube welding machine in the manufacturing industry

A high frequency seamless tube welding machine is a revolutionary technology that has changed the manufacturing industry. This machine has a wide range of applications in the industry, making it an essential piece of equipment for companies that produce tubes and pipes. One of the primary applications of this machine is in the production of seamless tubes. The machine is used to join two pieces of metal together to create a seamless tube without a weld seam. This makes the tube much stronger and more durable than a tube with a weld seam. The machine is also used to produce pipes and tubes for a wide range of applications, including construction, transportation, and plumbing. Additionally, the high frequency seamless tube welding machine is used in the production of heat exchangers, which are used in the chemical and oil industries. The machine is also used in the production of boilers, which are essential in power plants and other industrial settings. In summary, the high frequency seamless tube welding machine has a wide range of applications in the manufacturing industry. It is used to produce seamless tubes, pipes, heat exchangers, and boilers, among other products. Its ability to produce seamless tubes without weld seams makes it an essential piece of equipment in the industry, as it helps to create products that are stronger and more durable than those produced with traditional welding methods.

Overall, high frequency seamless tube welding machines are an essential tool for the production of seamless steel tubes. By choosing the right equipment and maintaining it properly, manufacturers can ensure the efficiency, quality, and reliability of their tube welding operations.