-

1/7

-

2/7

-

3/7

-

4/7

-

5/7

-

6/7

induction seam welder

Induction Seam Welder For Welding Tube and Pipe Solutions

What is induction welding?

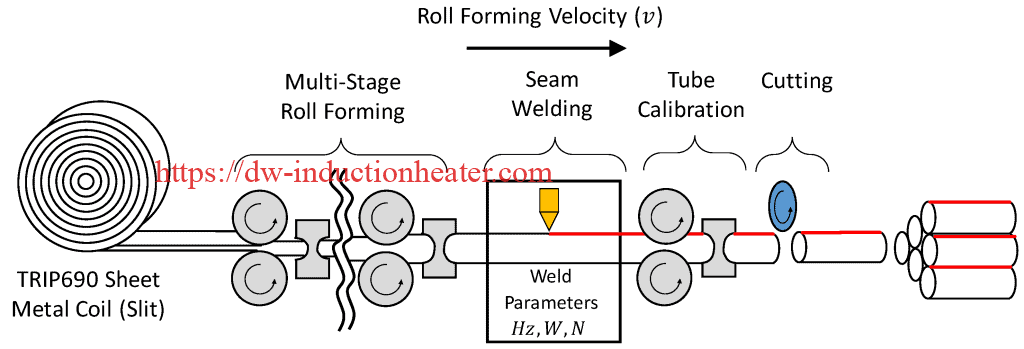

With induction welding, the heat is electromagnetically induced in the workpiece. The speed and accuracy of induction welding makes it ideal for edge welding of tubes and pipes. In this process, pipes pass an induction coil at high speed. As they do so, their edges are heated, then squeezed together to form a longitudinal weld seam. Induction welding is particularly suitable for high-volume production. Induction welders can also be fitted with contact heads, turning them into dual purpose welding systems.

With induction welding, the heat is electromagnetically induced in the workpiece. The speed and accuracy of induction welding makes it ideal for edge welding of tubes and pipes. In this process, pipes pass an induction coil at high speed. As they do so, their edges are heated, then squeezed together to form a longitudinal weld seam. Induction welding is particularly suitable for high-volume production. Induction welders can also be fitted with contact heads, turning them into dual purpose welding systems.

What are the advantages of induction Seam welding?

Automated induction longitudinal welding is a reliable, high-throughput process. The low power consumption and high efficiency of HLQ Induction welding systems reduce costs. Their controllability and repeatability minimize scrap. Our systems are also flexible—automatic load matching ensures full output power across a wide range of tube sizes. And their small footprint make them easy to integrate or retrofit into production lines.

Automated induction longitudinal welding is a reliable, high-throughput process. The low power consumption and high efficiency of HLQ Induction welding systems reduce costs. Their controllability and repeatability minimize scrap. Our systems are also flexible—automatic load matching ensures full output power across a wide range of tube sizes. And their small footprint make them easy to integrate or retrofit into production lines.

Where is induction seam welding used?

Induction welding is used in the tube and pipe industry for the longitudinal welding of stainless steel (magnetic and non-magnetic), aluminum, low-carbon and high-strength low-alloy (HSLA) steels and many other conductive materials.

High Frequency Induction Seam Welder

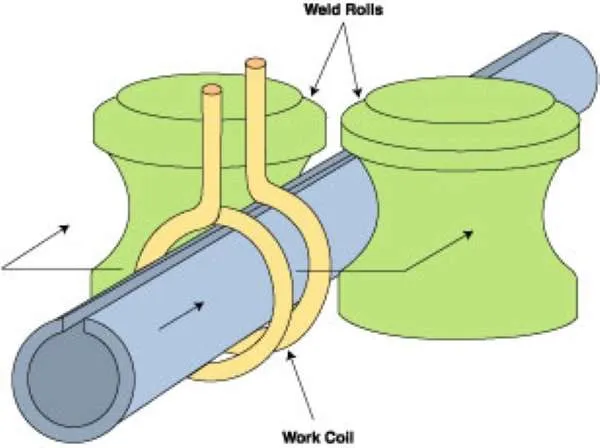

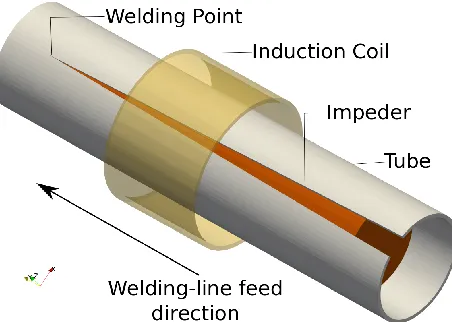

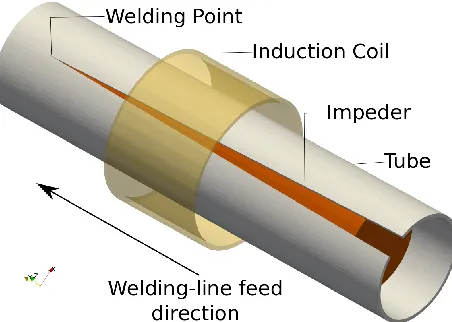

In the high frequency induction tube welding process, high frequency current is induced in the open seam tube by an induction coil located ahead of (upstream from) the weld point, as shown in Fig. 1-1. The tube edges are spaced apart when they go through the coil, forming an open vee whose apex is slightly ahead of the weld point. The coil does not contact the tube.

The coil acts as the primary of a high frequency transformer, and the open seam tube acts as a one-turn secondary. As in general induction heating applications, the induced current path in the work piece tends to conform to the shape of the induction coil. Most of the induced current completes its path around the formed strip by flowing along the edges and crowding around the apex of the vee-shaped opening in the strip.

The high frequency current density is highest in the edges near the apex and at the apex itself. Rapid heating takes place, causing the edges to be at welding temperature when they arrive at the apex. Pressure rolls force the heated edges together, completing the weld.

It is the high frequency of the welding current that is responsible for the concentrated heating along the vee edges. It has another advantage, namely that only a very small portion of the total current finds its’ way around the back of the formed strip. Unless the diameter of the tube is very small compared with the vee length, the current prefers the useful path along the edges of the tube forming the vee.

Product: Induction Seam Welder

| All Solid State (MOSFET) High Frequency Induction Seam Welder For Tube and Pipe | ||||||

| Model | GPWP-60 | GPWP-100 | GPWP-150 | GPWP-200 | GPWP-250 | GPWP-300 |

| Input power | 60KW | 100KW | 150KW | 200KW | 250KW | 300KW |

| Input voltage | 3Phases,380/400/480V | |||||

| DC Voltage | 0-250V | |||||

| DC Current | 0-300A | 0-500A | 800A | 1000A | 1250A | 1500A |

| Frequency | 200-500KHz | |||||

| Output efficiency | 85%-95% | |||||

| Power factor | Full load>0.88 | |||||

| Cooling Water Pressure | >0.3MPa | |||||

| Cooling Water Flow | >60L/min | >83L/min | >114L/min | >114L/min | >160L/min | >160L/min |

| Inlet water temperature | <35°C | |||||

True all-solid-state IGBT power adjustment and variable current control technology, using unique IGBT soft-switching high-frequency chopping and amorphous filtering for power regulation, high-speed and precise soft-switching IGBT inverter control, to achieve 100-800KHZ/3 -300KW product application.

- Imported high-power resonant capacitors are used to obtain stable resonant frequency, effectively improve product quality, and realize the stability of the welded pipe process.

- Replace the traditional thyristor power adjustment technology with high-frequency chopping power adjustment technology to achieve microsecond level control, greatly realize the rapid adjustment and stability of the power output of the welding pipe process, the output ripple is extremely small, and the oscillation current is stable. The smoothness and straightness of the weld seam are guaranteed.

- Security. There is no high frequency and high voltage of 10,000 volts in the equipment, which can effectively avoid radiation, interference, discharge, ignition and other phenomena.

- It has a strong ability to resist network voltage fluctuations.

- It has a high power factor in the whole power range, which can effectively save energy.

- High efficiency and energy saving. The equipment adopts high-power soft switching technology from input to output, which minimizes power loss and obtains extremely high electrical efficiency, and has extremely high power factor in the full power range, effectively saving energy, which is different from traditional Compared with the tube type high frequency, it can save 30-40% of the energy saving effect.

- The equipment is miniaturized and integrated, which greatly saves the occupied space. The equipment does not need a step-down transformer, and does not need a power frequency large inductance for SCR adjustment. The small integrated structure brings convenience in installation, maintenance, transportation, and adjustment.

- The frequency range of 200-500KHZ realizes the welding of steel and stainless steel pipes.

HLQ Induction has the most comprehensive range of solutions for the tube and pipe industry. HLQ Induction Seam Welder is a proven solution for welding stainless steel, aluminum, low-carbon steel and high-strength steel and is possibly the world’s best induction welder.

More output: Continuous electronic load matching secures full power output across a wide range of tube sizes.

More uptime: Short-circuit-proof, safe and reliable operation.

Unrivalled efficiency: Diode rectifier with a constant power factor of 0.95 at all power levels, and an efficiency factor of 85-87%.

Eco and energy friendly: High efficiency saves energy and reduces cooling water consumption.

Easy to operate: An easy-to-use control panel with a minimum of manual settings makes the Induction Seam Welder extremely easy to operate.

Wide range of power sizes: From 40 kW up to 1000 kW. A frequency range of 200-500 kHz.Modern modular design: The small, compact footprint saves valuable floor-space and simplifies in-line integration. Up to 1000 kW available in a one-cabinet solution.

Wide range of power sizes: From 40 kW up to 1000 kW. A frequency range of 200-500 kHz.Modern modular design: The small, compact footprint saves valuable floor-space and simplifies in-line integration. Up to 1000 kW available in a one-cabinet solution.

Complete system: Consisting of a diode rectifier, inverter modules, output section, busbar and operator control system.

Unmatched warranty: three-year warranty on HLQ Induction Seam Welder inverter modules and driver cards.

Full range of consumables: Coils, ferrite, impeders and tube scarfing equipment.