-

1/3

-

2/3

Induction Bonding Rubber To Steel

Induction Bonding Rubber To Steel With High Frequency Heating System

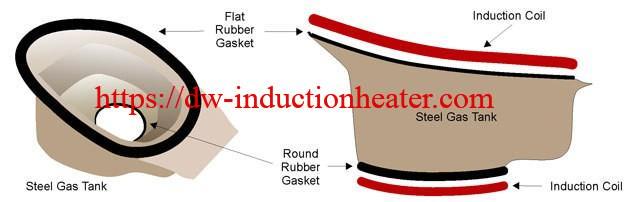

Objective To bond rubber gaskets to the top and bottom of a steel gas tank assembly.

Material Flat and round rubber gaskets, steel gas tank assembly

Temperature 300 to 350°F(148.9-176.7°C)

Frequency 200 kHz for the flat gasket; 231 kHz for the round gasket

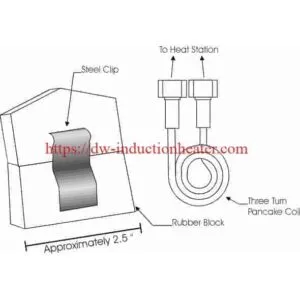

Equipment • DW-UHF-10kW induction heating system equipped with a remote workhead containing two 1.25 μF capacitors for a total of 0.625 μF

• An induction heating coil designed and developed specifically for this application.

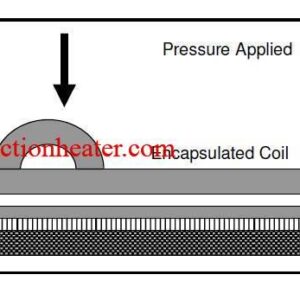

Process Two two-turn pancake coils are specially contoured to the the shape of the steel assembly to produce uniform heat in the gasket areas. The gaskets are positioned over the joint areas.

Power is applied for 6.5 seconds to reach the bonding temperature of 320°F (160°C).

Results/Benefits Induction heating provides:

• Repeatable, rapid & accurate heating cycles

• Reduced process time

• Even distribution of heat