-

1/3

-

2/3

-

3/3

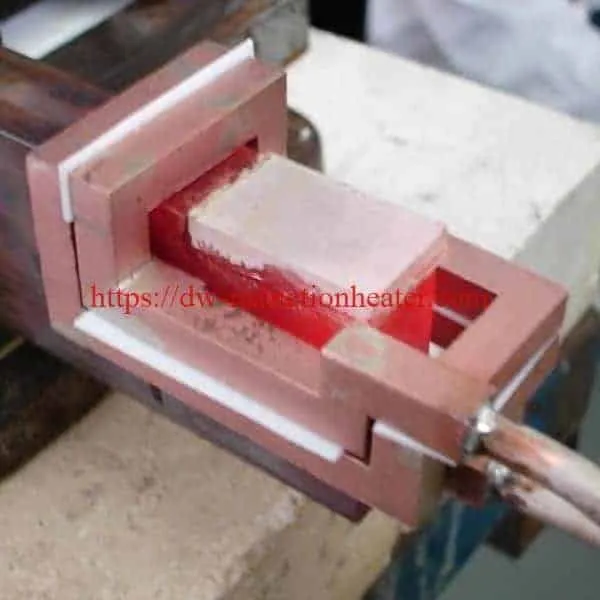

Electromagnetic Induction Brazing Equipment

Electromagnetic Induction Brazing Equipment

| Model | DW-UHF-60KW | |

| Input Voltage | 3 phase,380V,50-60Hz | |

| Output Power | 60KW | |

| Oscillate frequency | 30-150KHz | |

| Max Input Current | 90A | |

| Duty Cycle | 100% | |

| Heating Current | 15-145A | |

| Weight | 120KG | |

| Size | Main | 680X370X640mm |

| Heaer | 530X330X480mm | |

Main characteristics

1.With high frequency up to 150KHZ , and very thin and tiny parts can be easily heated.

2.IGBT and current inverting technologies have been used; higher reliability and lower maintenace cost.

3.100% duty cycle, continuous working is allowed at maximum power output.

4.Constant current or constant power status can be selected accordingly to achieve higher heating efficiency;

5.Display of heating power and heating current and oscillating frequency.

6.Simple to install , installation can be done by unprofessional person very easily;

7.Light weight, small size;

8.different shape and size of induction coil can be changed easily to heat different parts.

9.Advantages of the model with timer: the power and the operating time of the heating period and the retain period can be preset respectively, to realize a simple heating curve, this model is suggested to use for batch production to improve the repeatability.

Applications:

Particularly designed for small precision pieces soldering,quenching,heating.

* Harden treatment for belt of saw,knife.

* Harden treatment for both sides belt of knife.

* Quenching valves.

* Heating electrode.

* Brazing of the saw tip.

* Quenching of the gear.

* Heating of the small screw.

* Drills forging or hardening.

* Brazing of the small PCB drills.

* Brazing for parts of jewellery.

* Brazing for parts of hardware.

* Brazing for the parts of optical spectacle frame.

* Soldering for DLC data link connector.

* Tin-Lead bonding Antennas.

* Tin soldering Coaxial Cable.

* Annealing the small parts.

* Brazing of the tools.

* Quenching of the small shaft.

* Shaping of the small shaft.