-

1/2

-

2/2

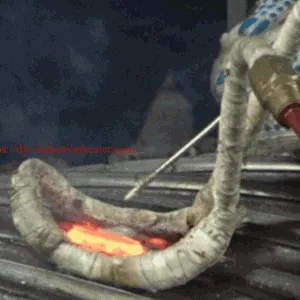

Brazing Steel Tube to Copper Tube with Induction Heater

Categories: Applications, Induction Brazing

Tags: Brazing, brazing steel tube, Buy induction brazing heater, buy steel tube brazer, copper tube, hf brazing steel tube, induction brazing, induction brazing steel tube process, induction heating steel tube, induction steel tube brazing, steel tube brazing copper tube, steel tube induction brazing, tube

High Frequency Induction Brazing Steel Tube to Copper Tube

Objective

The goal is to braze a steel tube to a copper tube in 60 seconds using flux and brazing alloy.

Equipment

DW-UHF-10kw induction brazing heater

Three turns dual diameter coil

Materials

• Steel tube and copper receiver

• Braze alloy (CDA 681)

• B-1 flux

Key Parameters

Temperature: Approximately 1750° F (954° C)

Frequency: 148 kHz

Process:

- The assembly section was pre-assembled and fluxed (B-1) then located in the two diameter coil with a single pre-formed alloy ring set at the interface area.

- Alloy flow and joint completed in 60 seconds.

- The material was cooled in water following the completion of induction brazing.

- The joint was then cross-sectioned to validate that the brazing process had produced a strong, high quality joint.

Results/Benefits:

- Strong durable joints with induction heating

- Selective and precise heat zone, resulting in less part distortion and joint stress than welding

- Less oxidation

- Faster heating cycles

- More consistent results and suitability for large volume production, without the need for batch processing

- Safer than flame brazing