Induction Heating for Dismounting and Dismantling of Couplings: The Safer and More Efficient Way

For anyone who works with heavy machinery, disassembling and dismantling couplings can be a challenging endeavor. However, with the help of induction heating technology, the process has become more efficient, safe, and cost-effective.

Couplings, which are used to connect two rotating shafts, are an essential component in many industrial applications. However, over time, these couplings can wear out, become damaged, or need to be replaced for maintenance purposes. In such situations, dismounting and dismantling the couplings can be a challenging and labor-intensive process, especially if traditional methods are used. Fortunately, induction heating technology is now available to make this process safer, faster, and more efficient.

Induction heating is a process of heating an electrically conductive material by inducing an electrical current through it. Induction heating has proven to be a reliable method for dismounting and dismantling couplings in various types of heavy machinery. The technology has been adopted in several industries, including power generation, oil and gas, marine, mining, pulp and paper, and steel mills, among others.

The conventional method of dismounting and dismantling couplings involves using hammers, pry bars, and other tools to remove them forcefully, which can result in serious damage to the couplings, shafts, and bearings. This method also poses a safety risk to the workers. The process can be time-consuming and costly, as the machinery has to be shut down for a long period, leading to production downtime.

Induction heating technology offers a solution to these challenges. The method involves heating the coupling with an induction coil, which causes it to expand slightly, allowing it to be easily removed from the shaft. The process is quick, safe, and eliminates the risk of damaging the couplings, shafts, and bearings.

Induction heating technology also offers a non-destructive way of dismounting and dismantling couplings. The process does not damage the coupling or the shaft, which means that the same coupling can be re-installed without having to be replaced. Additionally, the technology has low power consumption, which makes it an environmentally friendly solution.

The technology can be applied to various types of couplings, including elastomeric, gear, grid, and fluid couplings. Induction heating technology can also be used to disassemble and dismantle other components of heavy machinery, including bearings, gears, and rotors.

What is Induction Heating?

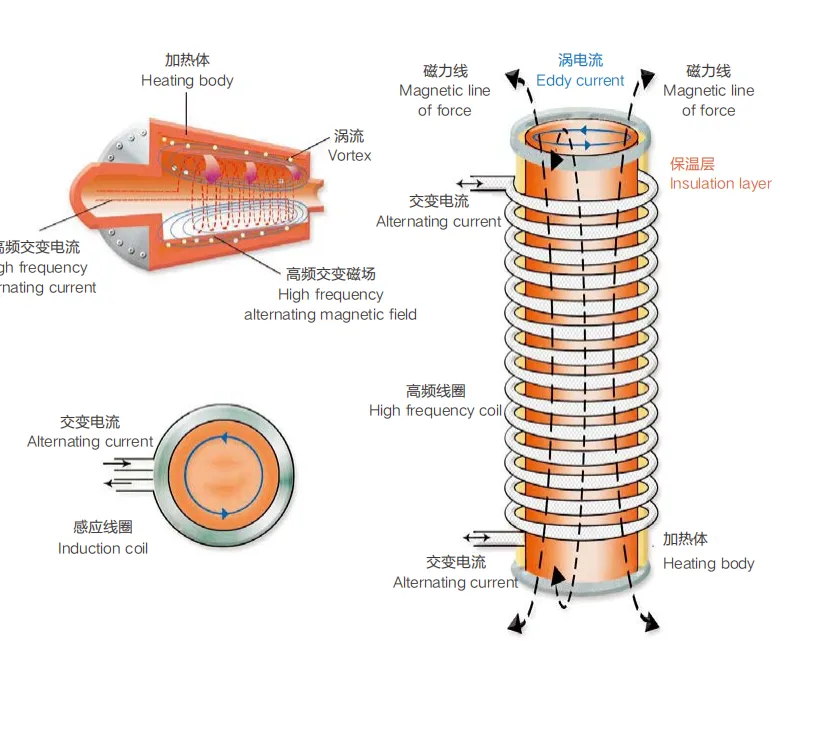

Induction heating is a process of heating an electrically conductive material by inducing an electrical current in it, using a strong magnetic field. This heat is generated within the material itself, rather than being applied from an external source, making it a highly efficient and precise method of heating. Induction heating can be used to heat various types of materials, including metals, plastics, and ceramics.

How Induction Heating is Used for Dismounting and Dismantling of Couplings

Induction heating technology is being increasingly used in the dismounting and dismantling of couplings. This is because it offers several advantages over traditional methods, such as open flame heating or mechanical disassembly. Induction heating is a non-contact method, which means that the heat is generated within the coupling itself, without the need to apply any external force, reducing the risk of damage to the coupling or the surrounding components.

When using induction heating for dismounting and dismantling of couplings, a special induction heating machine is used, which consists of an electromagnetic induction coil and a power supply. The induction coil is placed around the coupling, and a high-frequency alternating current is passed through it, creating a strong magnetic field that induces an electrical current in the coupling. This electrical current generates heat within the coupling, causing it to expand and loosen, making it easier to dismount or dismantle.

Induction heating machines for dismantling couplings come in various sizes and configurations. Some are designed for on-site use, while others are portable and can be used in the field. The machines are also designed to heat couplings of different sizes and materials. The induction heating equipment can be automated, allowing the process to be completed without human intervention.

Induction heating for dismounting and dismantling couplings offers significant advantages over traditional methods. First, it eliminates the risk of injury to workers, as the process can be completed without the use of force. Second, it reduces production downtime, enabling companies to improve their productivity levels. Third, it is cost-effective, as it eliminates the need for replacement or repair of damaged components.

Advantages of Induction Heating for Dismounting and Dismantling of Couplings

1. Safer: Induction heating is a safer method of heating, as it does not involve any open flames, reducing the risk of fire or explosion. It is also a non-contact method, which means that there is no risk of damage to the coupling or the surrounding components.

2. Faster: Induction heating is a faster method of heating, as it generates heat within the material itself, rather than being applied from an external source. This means that the coupling can be heated up to the required temperature more quickly, reducing the time required for dismounting and dismantling.

3. More efficient: Induction heating is a highly efficient method of heating, as it generates heat only in the area where it is needed, without wasting energy on heating the surrounding area. This means that it is a more environmentally friendly method of heating, as it minimizes energy consumption.

4. Precise: Induction heating is a precise method of heating, as the temperature can be controlled accurately. This means that the coupling can be heated up to the required temperature without exceeding it, reducing the risk of damage to the coupling or the surrounding components.

Conclusion

induction heating for dismounting and dismantling couplings is a reliable and effective method in heavy machinery. The technology helps to improve productivity, safety, and cost-effectiveness. It is an innovative solution that is gaining popularity in various industries, and those who adopt the technology can look forward to a safer, more efficient, and environmentally friendly future in heavy equipment maintenance.