Induction Aluminum Brazing: Techniques and Benefits Explained

Induction aluminum brazing is a process that involves joining two or more pieces of aluminum using a filler metal. This process is widely used in the automotive, aerospace, and HVAC industries, among others. In this article, we will discuss the basics of induction aluminum brazing and its advantages.

The induction aluminum brazing process starts with the selection of the right filler metal, which is essential for a strong and durable joint. The two pieces of aluminum are then prepared by cleaning them thoroughly and applying the filler metal to the joint area.

What is Induction Aluminum Brazing?

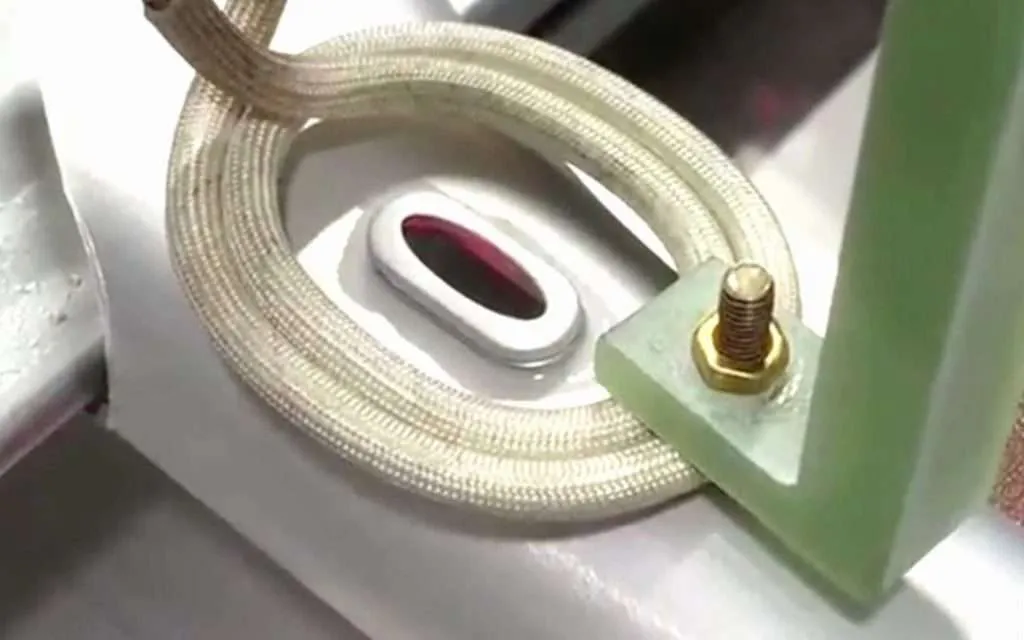

Induction aluminum brazing is a process that uses electromagnetic induction to heat the aluminum parts and the filler metal. The filler metal is melted and flows between the aluminum parts, creating a strong bond. This process is fast, efficient, and produces high-quality joints.

Advantages of Induction Aluminum Brazing :

Induction aluminum brazing offers several advantages over other brazing methods. Some of these advantages include:

1. High Quality Joints: Induction aluminum brazing produces high-quality joints that are strong and durable. The joints are also free of porosity and other defects that can weaken the bond.

2. Fast and Efficient: Induction aluminum brazing is a fast and efficient process that can join multiple parts in a short amount of time. This makes it ideal for high-volume production.

3. Precise Control: Induction aluminum brazing allows for precise control over the heating process, which ensures consistent results and reduces the risk of overheating or underheating.

4. Environmentally Friendly: Induction aluminum brazing is an environmentally friendly process that produces minimal waste and emissions.

Applications of Induction Aluminum Brazing Induction aluminum brazing is used in a wide range of applications, including:

1. Automotive: Induction aluminum brazing is used to join aluminum parts in cars and trucks, including radiators, condensers, and heat exchangers.

2. Aerospace: Induction aluminum brazing is used to join aluminum parts in aircraft, including heat exchangers, fuel tanks, and hydraulic systems.

3. HVAC: Induction aluminum brazing is used to join aluminum parts in HVAC systems, including evaporators, condensers, and heat exchangers.

4. Electrical: Induction aluminum brazing is used to join aluminum parts in electrical components, including transformers and motors.

Conclusion

Induction aluminum brazing is a fast, efficient, and high-quality process that is widely used in various industries. Its advantages include high-quality joints, fast and efficient production, precise control, and environmental friendliness. If you are looking for a reliable and efficient way to join aluminum parts, induction aluminum brazing is definitely worth considering.