High Frequency Induction Brazing Aluminum Tube T Joints

Objective

Induction brazing of multiple in line aluminum T tube joints for less than 10 seconds each and brazing an aluminum fitting into an aluminum tube 1.25″ (32mm).

The application is about brazing of an aluminum tube assembly consisting of two parallel tubes with outer diameter of 1.25″ (32mm), wall thickness 0.08″ (2mm) and length between 31.4″ (0.8m) to 86.6″ (2.2m). These tubes are connected in a ladder shape to smaller tubes with outer diameter of 0.7″(18mm), wall thickness 0.05″ (1.5mm) and length. The small tubes have 1.57″ (40mm) distance between each of the smaller tubes.

The application has two types of joints to be made:

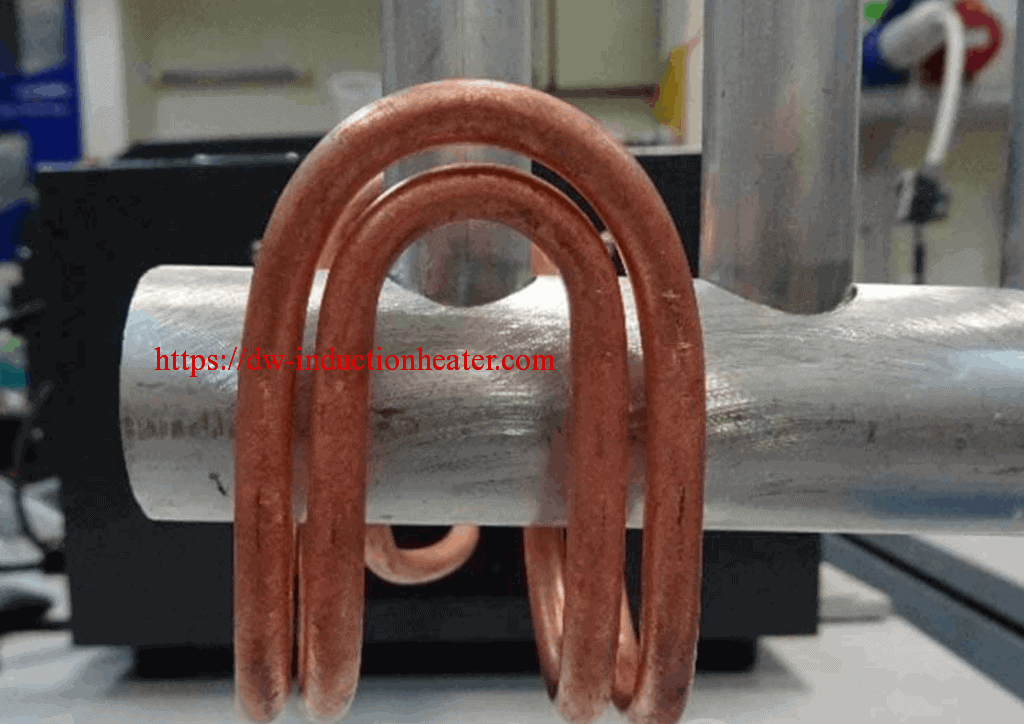

Joint 1: “T”-shape joint – between the bigger tube and the smaller tubes.

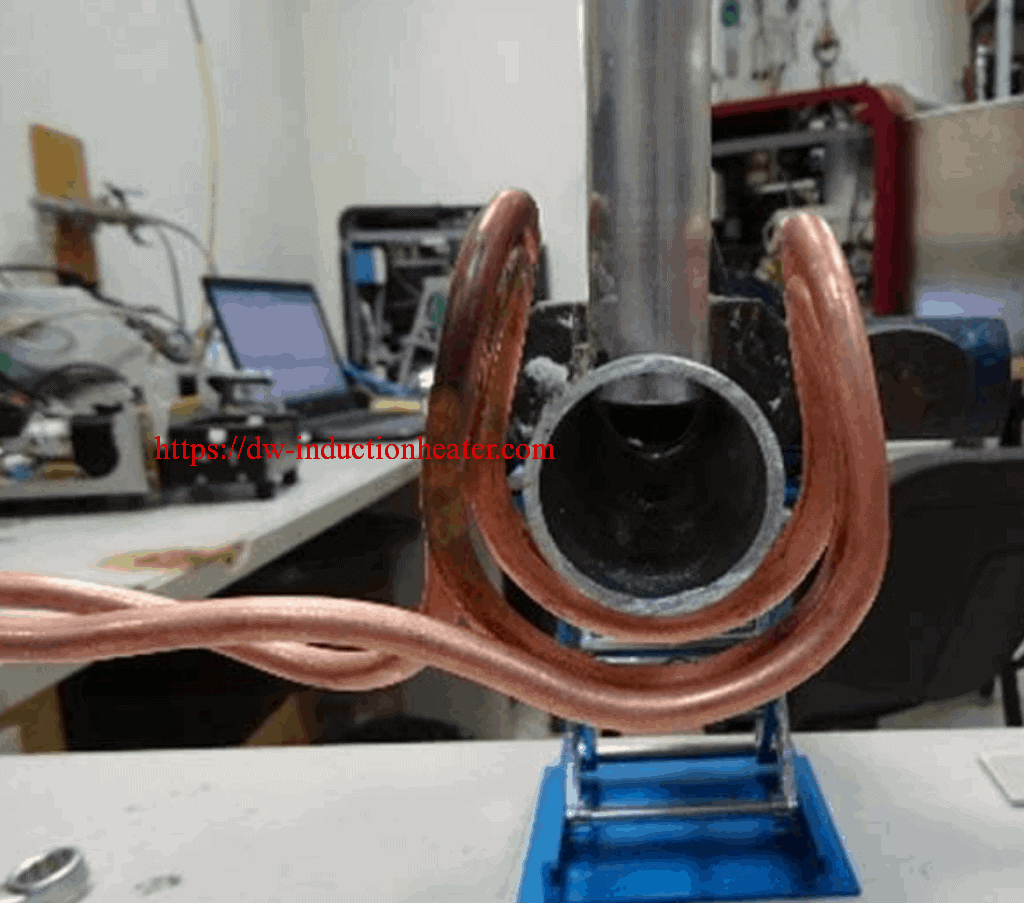

Joint 2: Joint to braze both ends of the bigger tubes with an aluminum fitting.

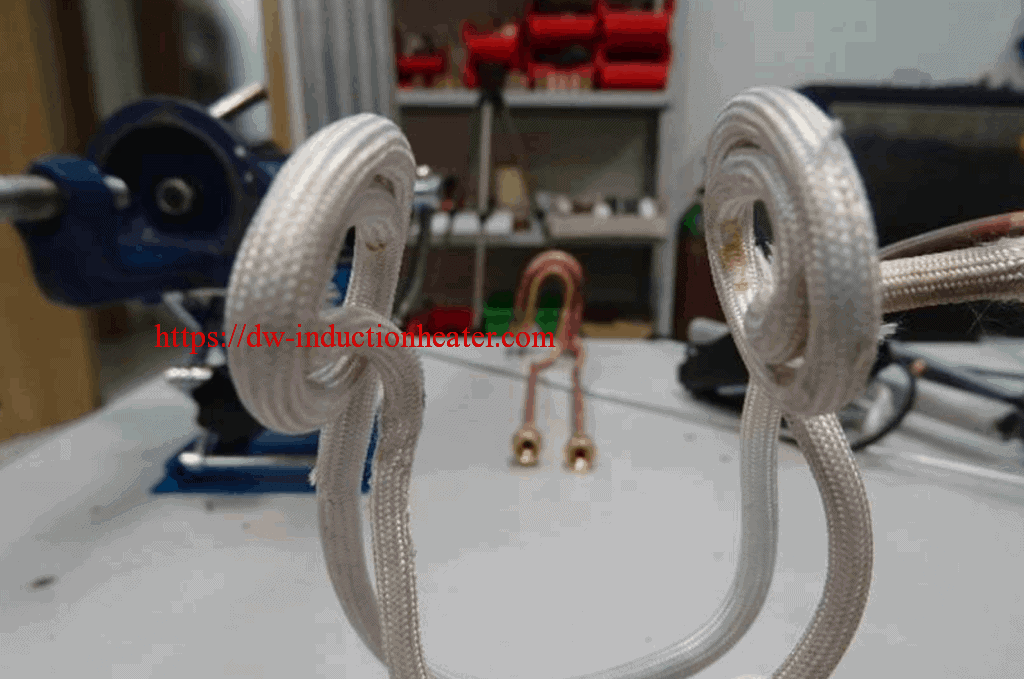

The requirements are the coil to be static and the whole mechanical assembly has stepping movement to make the T-shape joints. The fitting joints are made afterwards.

During the process, the bigger tubes are in a horizontal position while the smaller ones are vertical.

Our initial information was that access for brazing is allowed only from the side.

Recommended Equipment

Joint 1: The recommended induction brazing equipment for joint 1 is the DW-HF-4 5KW induction heating machine. A channel coil is

5KW induction heating machine. A channel coil is

recommended to help heat up 2 or 3 joints at the same time and temperature control to help maintain the appropriate temperature for the completion of the joints.

recommended to help heat up 2 or 3 joints at the same time and temperature control to help maintain the appropriate temperature for the completion of the joints.

Joint 2: The recommended equipment for joint 2 is the DW-HF-15kw induction heating machine.

Materials

Al tubes Ø 1.25″ (32mm) and Ø 0.7″(18mm)