Soldering Fiber Optic Cable for Hermetic Sealing With IGBT Induction Soldering Heater

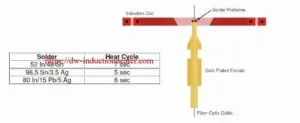

Objective To heat a Kovar ferrule and fiber optic cable to 297°F within 10 seconds for a soldering application, to form a hermetic seal

Material Gold-coated cable, Kovar ferrule, solder and flux

Temperature 297 ºF

Frequency 360 kHz

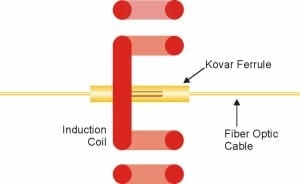

Equipment DW-UHF-4.5kW power supply with a specially designed induction coil

Process A specially designed, 4-turn “C” shape coil was used to provide uniform heat to the assembly near the joint area. With this design, the coil can be lowered directly onto the joint; it is not necessary to feed the ferrule assembly through the coil. Flux was applied to the assembly where the ferrule and fiber optic cable were to be joined. RF power was applied for 10 seconds, which caused the solder to melt and flow.

Results/Benefits Consistent and repeatable results were achieved with the DW-UHF-4.5kW power supply and a 10-second heat cycle. The solder flowed evenly and bonded the fiber optic cable to

the Kovar ferrule. With the induction coil’s compact design, a very small surface area was heated with pinpoint accuracy.