Induction Shrink Fit Aluminum Shaft with IGBT induction heating systems

Objective Heat aluminum impeller blades to 200 ºF (93 ºC) and shrink fit onto a shaft.

Material Aluminum impeller blades with a .28” (7.109mm) bore, aluminum shaft

Temperature 200 ºF (93 ºC)

Frequency 255 kHz

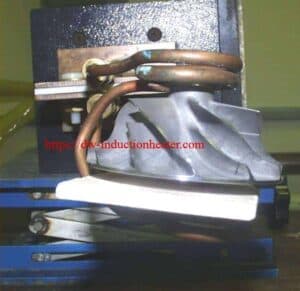

Equipment • DW-UHF-6W induction heating system, equipped with a remote workhead containing one 1.0μF capacitor.

• An induction heating coil designed and developed specifically for this application.

Process A split two turn helical coil is used to evenly heat the opening on the impeller blade. The impeller blade is heated for 20 seconds to reach the 200 ºF (93 ºC). The impeller blades are then removed from the coil & slipped over the shaft to complete the shrink fitting application.

Results/Benefits Induction heating provides:

• Repeatable results

• Reduced cycle time, lower consumables cost

• Even distribution of heating