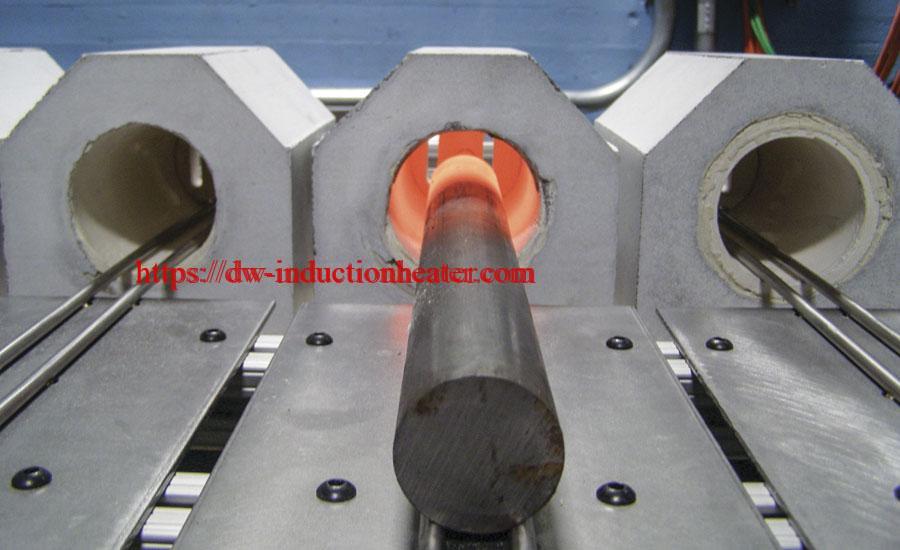

HLQ Induction Equipment Co is the World leader in the design and manufacture of induction heating products including those for induction bar end heating applications. Higher production rates can be achieved with the use of multiple solenoid coils while channel induction coils facilitate material handling of long bars through the use of chain conveyors to continuously feed the bars through the C-shaped coil.

Parameter of induction bar end heating furnace:

| DW-MF-200 | DW-MF-250 | DW-MF-300 | DW-MF-400 | DW-MF-500 | DW-MF-600 | ||

| Input Voltage | 3phases, 380V/410V/440V , 50/60Hz | ||||||

| Max Input Current | 320A | 400A | 480A | 640A | 800A | 960A | |

| Oscillating frequency | 0.5KHz^20KHz ( Oscillating frequency will be customized according to the size of heating parts) | ||||||

| Duty Cycle Loading | 100%,24h continuously work | ||||||

| Cooling Water Desires | 0.1MPa<Water Pressure<0.3MPa, Water hardness<50 | ||||||

| Dimension | Host | 1000X800X1500mm | 1500X800X2800mm | 850X1700X1900mm | |||

| Extension | extension will be customized according to the material and size of heating parts | ||||||

| Weight | 110kg | 150kg | 160kg | 170kg | 200kg | 220kg | |

| Depend on the dimension of extension | |||||||