Induction Heat Setting A Shape Memory Alloy With IGBT Induction Heater

Objective Heat a steel die to 975°F (523.8ºC) to set (cure) a shape memory alloy in the correct position.

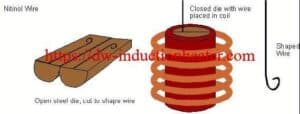

Material Nitinol wire, 2” (50.8mm) diameter tapered steel die, steel tube to house the die, instant adhesive

Temperature 975°F(523.8ºC)

Frequency 131kHz

Equipment • DW-UHF-6kW induction heating system equipped with a remote workhead containing one 1.0 μF capacitor

• An induction heating coil designed and developed specifically for this application.

Process A five turn helical coil is used to heat the steel die. The Nitinol wire is set into the die and tacked into place using instant adhesive. The die is placed inside a larger steel tube. The die cure is heated to 945ºF (507.2ºC) in 75 seconds. Successful heat setting of the Nitinol wire is achieved in 15 seconds.

Results/Benefits Induction heating provides:

• Fast, accurate, repeatable heating

• Heat precisely delivered only to where it is needed