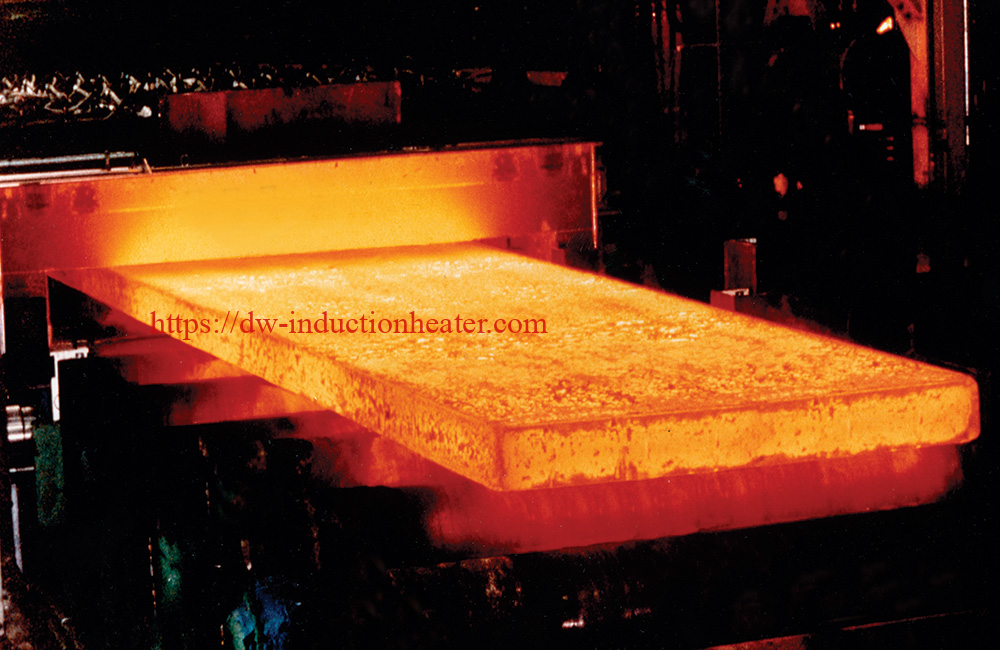

Induction heating steel sheet is a process that involves using an electromagnetic field to heat up a metal object. In this case, the object is a steel sheet. The steel sheet is placed within the electromagnetic field, and the energy from the field causes the steel to heat up. This method of heating is fast and efficient, and it can be used for a variety of purposes, including annealing, hardening, and welding. Induction heating is also a more precise method of heating, as the heat can be localized to specific areas of the steel sheet. This means that there is less risk of overheating or damaging the steel sheet during the heating process. Overall, induction heating is a great option for anyone who needs to heat up steel sheets quickly, efficiently, and with precision.

1. What is induction heating steel sheet production?

Induction heating is a type of heating that is commonly used for steel sheet production. It is a process that uses electromagnetic induction to heat the metal. This technique is particularly useful for steel sheet production because it offers numerous advantages over traditional heating methods. Induction heating is a fast and efficient way to heat steel sheets. By using high-frequency electromagnetic currents, it can heat the metal quickly and evenly. This can lead to a more consistent product with fewer defects. Another advantage of induction heating is that it is a clean and safe process. Unlike other heating methods, induction heating doesn’t produce emissions or require the use of fossil fuels. This makes it a more environmentally friendly option. Additionally, induction heating doesn’t require a flame or other heat source, which reduces the risk of fire or other accidents. Induction heating is also a cost-effective option for steel sheet production. Because it is a quick and efficient process, it can save both time and money in the production process. Additionally, the even heating that induction heating provides can reduce the need for additional processing steps, which can also save money. Overall, induction heating for steel sheet production is an excellent choice for those looking for a fast, efficient, and cost-effective heating method. Its numerous advantages make it a popular choice in many industries, including automotive, aerospace, and construction.

2. Advantages of induction heating over traditional methods

Induction heating has become a popular choice in steel sheet production because of its numerous advantages over traditional heating methods.  One of the most significant advantages of induction heating is that it can be more energy-efficient than other heating methods. With traditional heating methods, a lot of energy is lost as the heat is transferred from the heating element to the metal. With induction heating, however, the heat is produced directly within the metal, resulting in a more efficient heating process. This translates to lower energy costs and a reduced carbon footprint. Another advantage of induction heating is that it can provide a more precise and controlled heat source. This is because induction heating uses a magnetic field to generate heat, which allows for more accurate temperature control. This ability to control the temperature more precisely results in a more consistent heating process, which ultimately leads to higher quality steel sheet production. Furthermore, induction heating can also be a safer option for steel sheet production. With traditional heating methods, there is often an open flame or other heating element that can pose a safety risk. Induction heating, on the other hand, does not require an open flame, making it a safer option for both workers and the environment. Overall, the advantages of induction heating make it a popular choice for steel sheet production. Its energy efficiency, precision, and safety make it a more effective and sustainable option for heating steel sheets.

One of the most significant advantages of induction heating is that it can be more energy-efficient than other heating methods. With traditional heating methods, a lot of energy is lost as the heat is transferred from the heating element to the metal. With induction heating, however, the heat is produced directly within the metal, resulting in a more efficient heating process. This translates to lower energy costs and a reduced carbon footprint. Another advantage of induction heating is that it can provide a more precise and controlled heat source. This is because induction heating uses a magnetic field to generate heat, which allows for more accurate temperature control. This ability to control the temperature more precisely results in a more consistent heating process, which ultimately leads to higher quality steel sheet production. Furthermore, induction heating can also be a safer option for steel sheet production. With traditional heating methods, there is often an open flame or other heating element that can pose a safety risk. Induction heating, on the other hand, does not require an open flame, making it a safer option for both workers and the environment. Overall, the advantages of induction heating make it a popular choice for steel sheet production. Its energy efficiency, precision, and safety make it a more effective and sustainable option for heating steel sheets.

3. The impact of induction heating on steel sheet production quality

Induction heating has revolutionized steel sheet production by enhancing the quality of the final product. When steel sheets are heated using induction heating, they experience a rapid, localized, and precise heating process that results in a uniform temperature distribution across the steel sheet. This uniform heating process ensures that the steel sheet is heated precisely, avoiding any chances of overheating or under-heating that could result in defects in the final product. Furthermore, induction heating offers a more controlled heating process compared to other traditional heating methods like the use of gas or oil. This means that the steel sheet won’t come into contact with any harmful impurities during the heating process, as induction heating is a clean and precise process. This results in a high-quality steel sheet that is uniform, clean, and free from any impurities. The impact of induction heating on steel sheet production quality is significant. It increases the quality, consistency, and efficiency of the heating process. The precise induction heating process eliminates the risk of defects in the final product, reducing rework and scrap rates. As a result, induction heating reduces overall production costs and improves the profitability of steel sheet manufacturing companies. In conclusion, the advantages of induction heating for steel sheet production are numerous, and it represents a significant step forward in the steel manufacturing industry.

4. Conclusion.

In conclusion, Induction heating steel sheet is a process that uses an alternating magnetic field to heat up steel sheets. The heating is caused by the eddy currents that are induced in the steel sheet as a result of the alternating magnetic field. Induction heating is a very efficient and precise method of heating steel sheets, as it can be controlled with great accuracy. This makes it an ideal method for heat treatment processes, such as annealing, hardening, and tempering. Induction heating is also used in welding, brazing, and soldering applications, as well as in the manufacturing of various steel products such as pipes, tubes, and sheets. It is a versatile and widely used technology in the steel industry, offering precise control and energy efficiency.