Induction Fluid Pipeline heating system

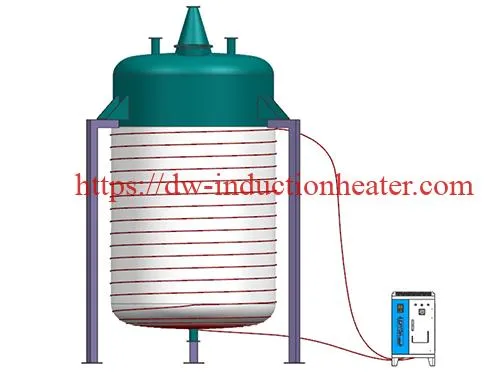

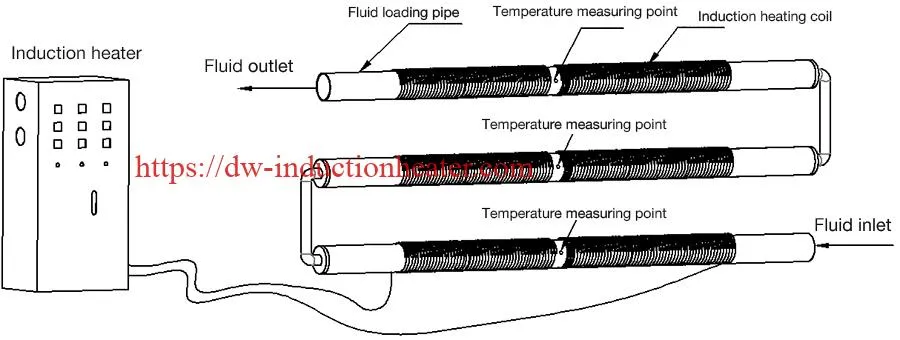

HLQ Induction Heating Equipment is designed for Pipeline, Vessel, Heat Exchanger, Chemical Reactor and Boiler. The vessels transfers heat to the fluid materials like Industrial Water, Oil, Gas, Food Material and Chemical Raw Materials heating. Heating Power size 2.5KW-100KW is the air cooled ones. Power size 120KW-600KW is the water cooled ones. For some on site chemical material reactor heating, We will supply the heating system with Explosion Proof Configuration and Remote Control System.

This HLQ heating system consists induction heater, induction coil, temperature control system, thermal couple and insulation materials. Our company provides installation and commissioning scheme. The user can install and debug by yourself. We can also provide on-site installation and commissioning. The key of power selection of fluid heating equipment is the calculation of heat and heat exchange area.

HLQ Induction Heating Equipment 2.5KW-100KW air cooled and 120KW-600KW water cooled.

Energy Efficiency Comparison

| Heating method | Conditions | Power consumption |

| Induction heating | Heating 10 liters of water up to 50ºC | 0.583kWh |

| Resistance heating | Heating 10 liters of water up to 50ºC | 0.833kWh |

Comparison between Induction Heating and Coal/Gas/Resistance Heating

| Items | Induction heating | Coal-fired heating | Gas-fired heating | Resistance heating |

| Heating efficiency | 98% | 30-65% | 80% | Below 80% |

| Pollutant emissions | No noise, no dust, no exhaust gas, no waste residue | Coal cinders, smoke, carbon dioxide, sulfur dioxide | Carbon dioxide, sulfur dioxide | Non |

| Fouling (pipe wall) | Non-fouling | Fouling | Fouling | Fouling |

| Water softener | Depending on the quality of fluid | Required | Required | Required |

| Heating stability | Constant | Power is decreased by 8% yearly | Power is decreased by 8% yearly | Power is decreased by more than 20% yearly (high power consumption) |

| Safety | Electricity and water separation, no electricity leakage, no radiation | Risk of carbon monoxide poisoning | Risk of carbon monoxide poisoning and exposure | Risk of electricity leakage, electric shock or fire |

| Durability | With core design of heating, 30 years service life | 5 years | 5 to 8 years | Half to one year |

Diagram

Induction Heating Power Calculation

Induction Heating Power Calculation

Required parameters of parts to be heated: specific heat capacity, weight, starting temperature and end temperature, heating time;

Calculation formula: specific heat capacity J/(kg*ºC)×temperature differenceºC×weight KG ÷ time S = power W

For example, to heat thermal oil of 1 ton from 20ºC to 200ºC within an hour, the power calculation is as follows:

Specific heat capacity: 2100J/(kg*ºC)

Temperature difference: 200ºC-20ºC=180ºC

Weight: 1ton=1000kg

Time: 1 hour=3600 seconds

i.e. 2100 J/ (kg*ºC)×(200ºC -20 ºC)×1000kg ÷3600s=105000W=105kW

Conclusion

The theoretical power is 105kW, but the actual power is commonly increased by 20% because of taking the heat loss into consideration, that is, the actual power is 120kW. Two sets of 60kW induction heating system as a combination are required.