Induction Brazing of short circuit rings of electrical motors

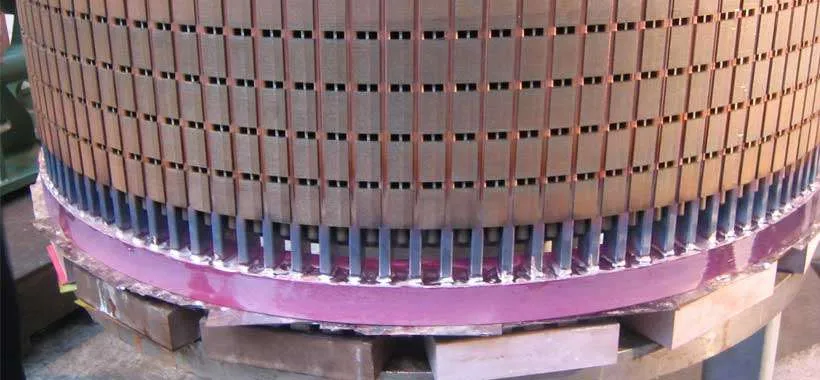

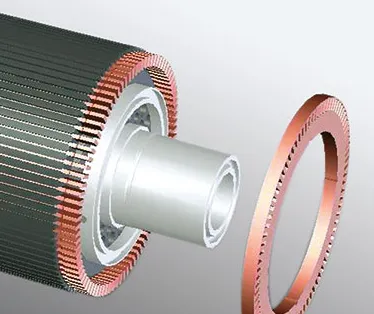

Short-circuit ring is brazed to rotors in electric motors, particularly in the motors called “squirrel cage”, name used to call the rotor and the whole motor itself. The temperature homogeneity in the ring is absolutely critical to meet the technical requirements in the final motor or generator. So the control process and brazing experience in this field are a must.

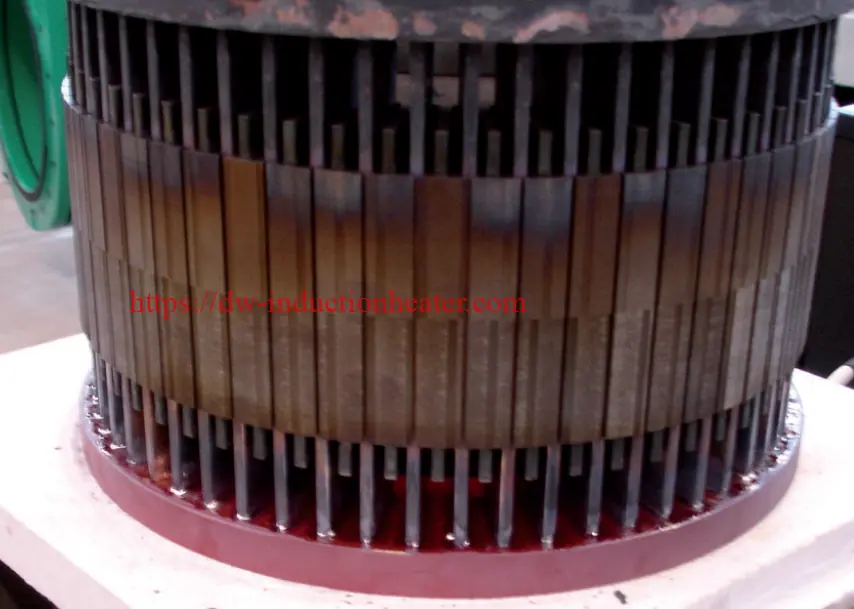

Induction heating offers numerous advantages over traditional flame methods for brazing short-circuit rings (SCRs). One key advantage is that induction generates a more homogeneous temperature distribution around the SCR. Also, as induction heating can be very precisely controlled, overheating of the copper bars is avoided. Finally, induction heating is fast. Its accuracy and repeatability means it can boost throughput without sacrificing quality.

SCR/ short circuit ring induction brazing can be done in two ways: single shot and segment brazing. The major difference between the two methods is that the former needs more heating power. When the diameter of the SCR is less than 1200 mm, single shot brazing is used.HLQ Induction Equipment’s series power generators provide a wide range of heating power from 25 KW up to 200/320 KW. A temperature regulating system can be integrated into infrared temperature controller for closed loop control of the brazing power. Normally there are two controlled pyrometers in the system: one for measuring the temperature in the SCR and the other for measuring the temperature on the copper bar to ensure it reaches the brazing temperature.

HLQ Induction’s unique induction heating coil design, together with induction heating’s speed and accuracy, mean minimal heat inputs. This in turn reduces the risk of shafts weakening, and minimizes heat transfer into the laminations, a common problem when using flame brazing. Induction brazing also prevents other problems associated with flame heating. For example, the accuracy of induction heating reduces the risk of ovality, and the subsequent need to re-balance squirrel cage motors. Open flames risk overheating the flux material,

compromising its capability to prevent the formation of oxides in the joint. The copper, too, risks overheating, which can lead to unwanted grain growth. But with induction heating the temperature is precisely controlled. Induction heating also has environmental and safety advantages. It’s easy to remove any fumes. Noise levels and ambient temperature increases are negligible.

HLQ Induction can provide customized, turn-key solutions for virtually any SCR brazing task. These solutions include the equipment, optimized temperature curves, customized coils and a comprehensive range of training and service support.

HLQ Induction Equipment Co provides solutions covering either Medium to High Power motors and generators with more than 20 year experience around the world. This application in part of a wider portfolio for this industry.

INDUCTION BRAZING BENEFITS vs ALTERNATIVE PROCESSES

Controlled process: homogenization of the heating and temperature control all around the ring .

Fast process (higher power density), about 10 times less than flame

Heating by ramps totally controlled and warranted or even cooling by ramps

Repeatability and traceability

SIMPLIFIED PROCESS

1.No dedusting required

2.Less distortions, no rebalanced required

3.Low oxide formation

4.Operator expertise brazing skills are not too critical

5.Running costs lower than torch

6.ECO & USER-FRIENDLY OPERATION

Safer process:

1.No flame or gas, minimized risks

2.Clear view of the process by operator at any moment

3.Environmental friendly

4.Easy to remove fumes

Induction Brazing Solution:

HLQ Induction Brazing Solutions for short-circuit ring brazing cover either Medium to High Power motors and generators.

1.Specialized coil for extreme temperature uniformity all over the ring

2.Advanced temperature control either fully atomized process or managed by the brazer

RELATED PRODUCTS

Rotor Short circuit ring brazing

Stator Copper Strip brazing

Rotor Shaft shrink fitting

Housing shrink fitting